Introduction to Metal Sheet Vacuum Lifters for Heavy Large-Format Sheet Metal and Metal Plates Up to 2,000kg: DC12V Rechargeable Electric Vacuum Lifter

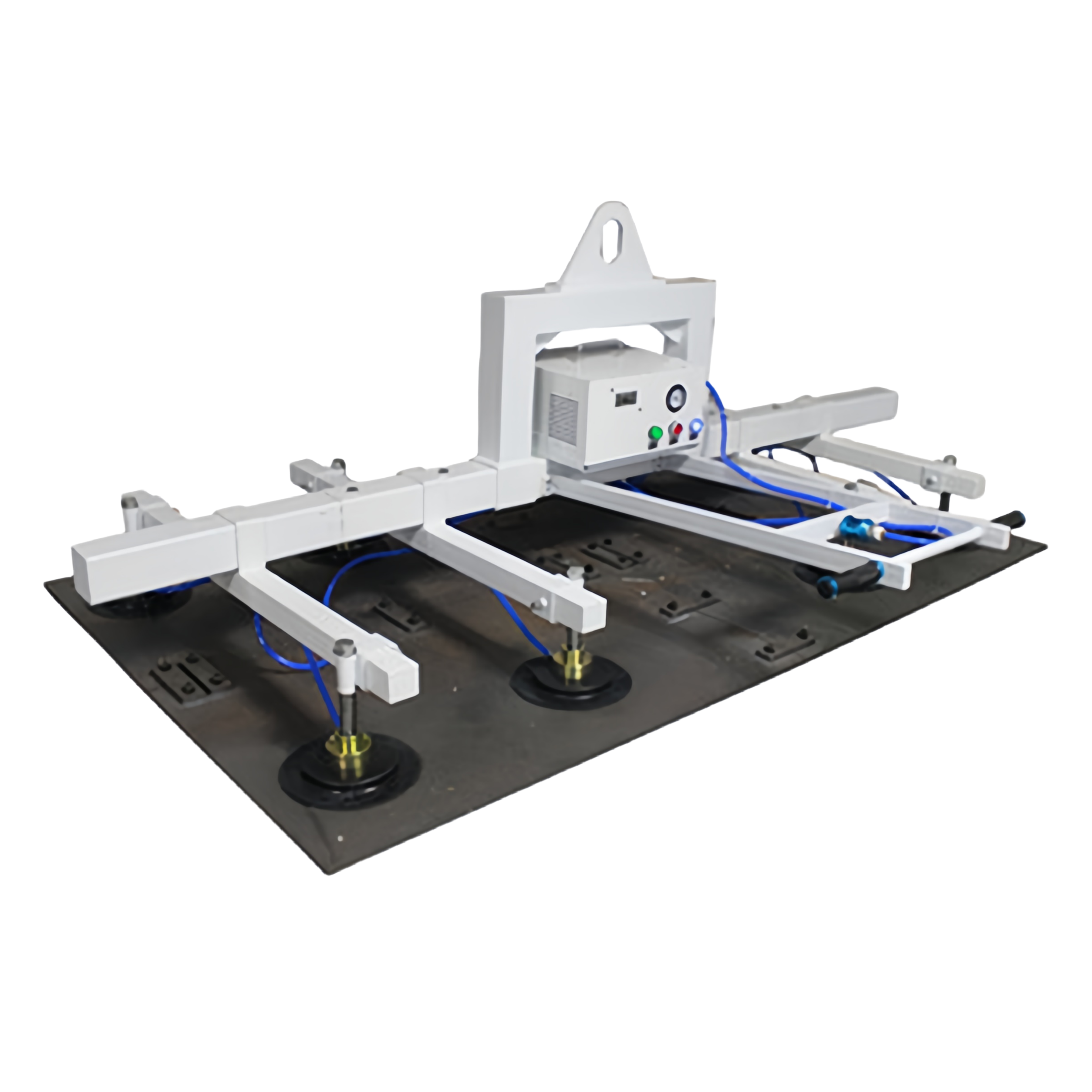

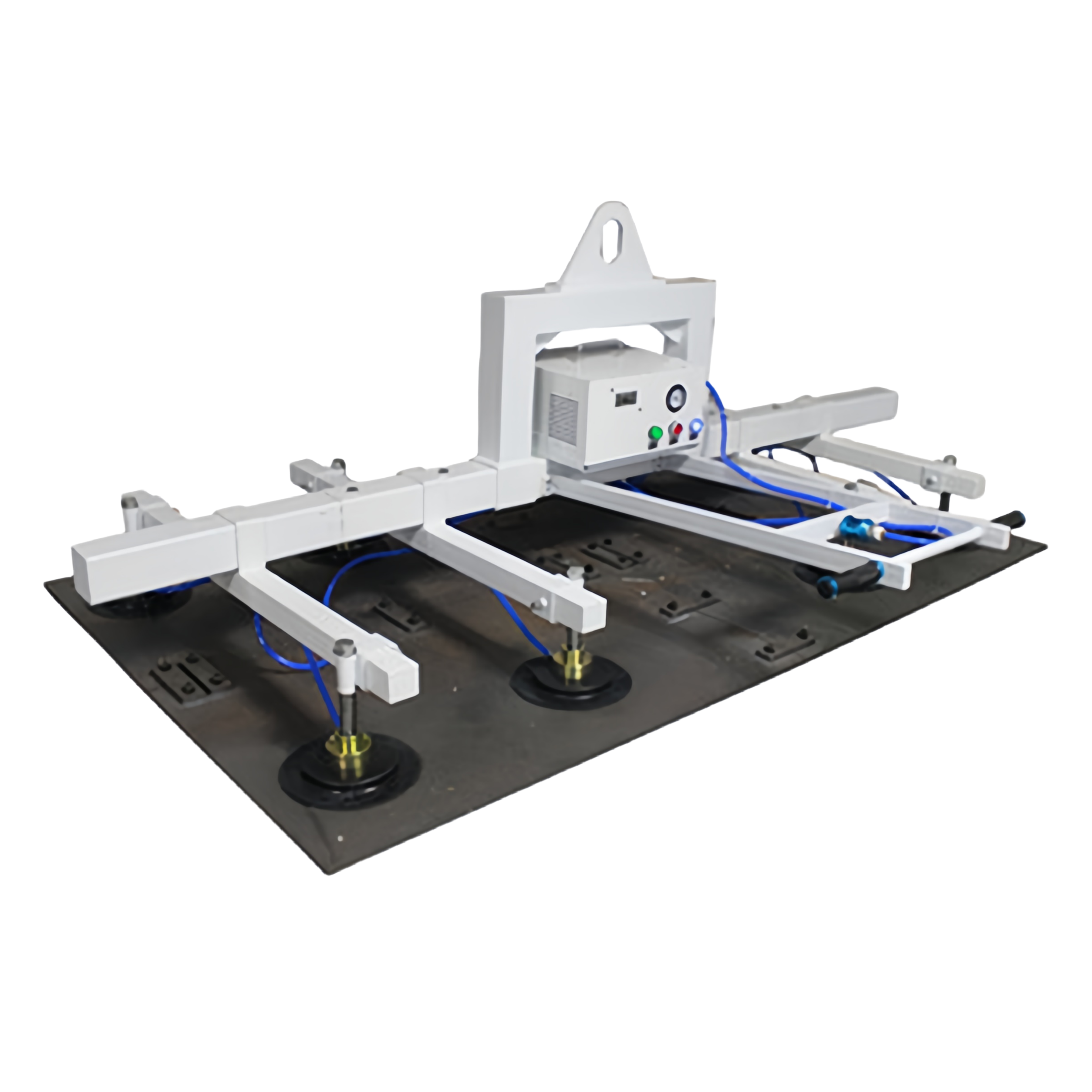

In industries such as metalworking, construction, automotive manufacturing, and metal processing, the ability to safely and efficiently handle heavy, large-format sheet metal and metal plates is crucial for maximizing productivity and ensuring worker safety. The Metal Sheet Vacuum Lifters for Heavy Large-Format Sheet Metal and Metal Plates up to 2,000kg are advanced lifting systems designed to address the challenges of lifting, moving, and positioning heavy metal materials with precision and ease. These lifters feature DC12V rechargeable electric power, making them both portable and energy-efficient, ideal for various industrial applications.

With a remarkable lifting capacity of up to 2,000kg, these vacuum lifters are engineered to handle even the heaviest metal sheets and plates, providing a secure and reliable lifting solution without compromising safety or efficiency. Whether you need to lift large steel panels in a metal fabrication facility, move heavy aluminum plates in automotive manufacturing, or handle thick steel sheets in construction, these vacuum lifters are designed to handle the toughest lifting tasks with ease.

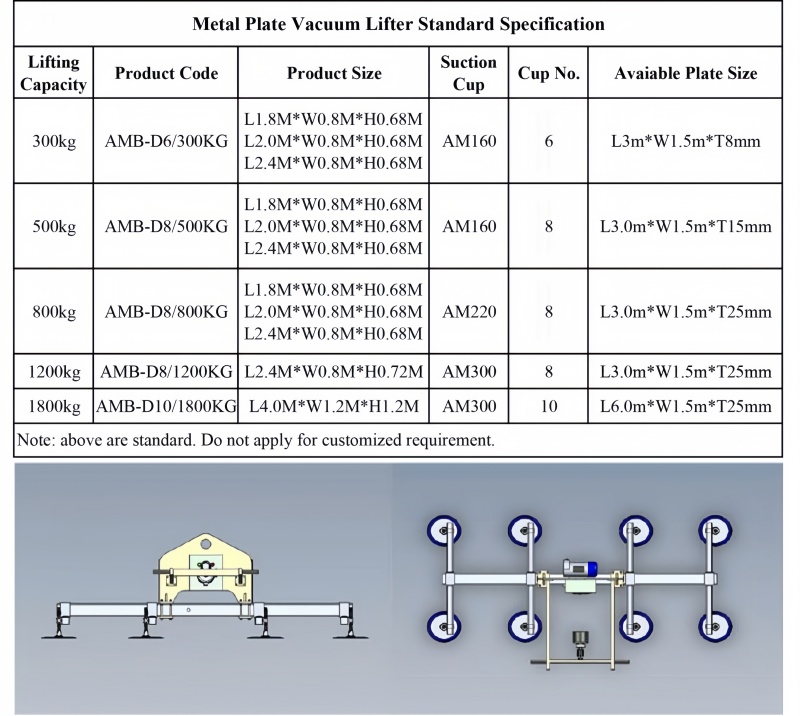

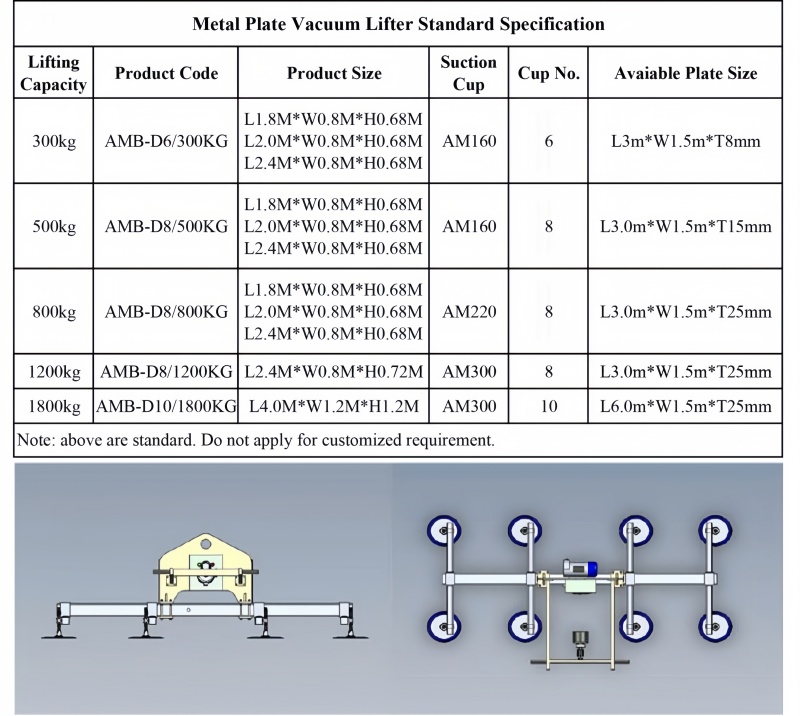

| Product Type | Rechargeable Lifter | Plug-in Lifter |

| Model | JS-J1000-5M | JS-J2000-5M | JS-C1000-25M | JS-C2000-5M |

| Rated Load (kg) | 1000 | 2000 | 1000 | 2000 |

| Suction Cup Diameter (mm) | 200 | 200 | 200 | 200 |

| Number of Suction Cups | 12 | 12 | 12 | 12 |

| Dimensions (mm) | 5000*1000 | 5000*1000 | 5000*1000 | 5000*1000 |

| Plate Size (mm) | 6000*2000 | 6000*2000 | 6000*2000 | 6000*2000 |

| Operating Power (V) | DC12V | DC12V | AC220V/380V | AC220V/380V |

Key Features of the Metal Sheet Vacuum Lifters

1. Impressive Lifting Capacity (Up to 2,000kg)

The primary feature of this electric vacuum lifter is its high lifting capacity of up to 2,000kg, making it suitable for lifting and handling heavy large-format sheet metal and metal plates. This high capacity allows industries to handle large steel plates, aluminum panels, or other materials without the need for multiple workers or bulky machinery.

With this 2,000kg capacity, operators can lift and transport heavy materials safely, improving efficiency and minimizing the physical strain on workers. It also reduces the risk of material damage, which can occur when lifting large metal sheets manually or using less secure lifting methods.

2. DC12V Rechargeable Battery Operation

This DC12V rechargeable battery power source is one of the most significant advantages of this lifter. Unlike traditional vacuum lifters that rely on power cords or compressed air, this electric lifter is battery-powered, making it more portable, flexible, and cost-effective.

Rechargeable Battery: The DC12V battery allows the lifter to operate independently, providing freedom of movement across production lines or different workstations without being tethered to a power supply.

Long Battery Life: The battery is designed for long-lasting operation, supporting multiple lifting cycles before needing to be recharged. This makes the lifter ideal for high-efficiency operations in factories and warehouses where large volumes of metal sheets need to be handled continuously.

3. Vacuum Lifting Technology for Safe and Secure Handling

The vacuum lifting technology used in this lifter ensures that the large metal plates are securely gripped without the risk of slipping or damage. The vacuum suction system provides a strong and reliable grip on materials, even when lifting heavy sheets of metal that weigh up to 2,000kg.

Adjustable Suction Pads: The lifter is equipped with adjustable suction pads that can accommodate different sizes of metal plates. Whether dealing with wide metal sheets, small steel panels, or large aluminum plates, the suction cups can adapt to different material sizes, ensuring a secure and efficient lift.

Powerful Suction: The lifter features a high-performance vacuum pump capable of generating sufficient suction to lift and hold large sheets securely, ensuring that the metal plates remain stable during transport.

4. Ergonomically Designed for Worker Safety and Comfort

Lifting large and heavy metal sheets manually can put significant strain on workers, leading to injuries and fatigue. This electric vacuum lifter is designed with ergonomics in mind, ensuring that workers can lift heavy materials safely and comfortably, reducing the risk of accidents.

Lightweight and Maneuverable: Despite its high lifting capacity, the lifter is designed to be lightweight and easy to maneuver. This allows operators to move heavy metal plates with minimal effort, even in tight or narrow spaces.

Ergonomic Controls: The lifter is equipped with user-friendly controls that allow operators to handle large metal sheets with ease. The controls are simple and intuitive, allowing for precise lifting, lowering, and placement of materials.

5. Versatility for Various Industrial Applications

This vacuum lifter is highly versatile and can be used in a range of industries where large metal sheets or plates are handled. Some of the key applications include:

Metalworking and Fabrication: Ideal for moving steel plates, aluminum sheets, and other metal materials to and from machines such as laser cutting, press brakes, and welding stations. The lifter ensures that materials are handled safely and efficiently during fabrication processes.

Automotive Manufacturing: Used for lifting and positioning large metal panels and components used in car body assembly or other manufacturing processes. The vacuum lifter provides a secure method for moving large, heavy parts during vehicle production.

Construction: In construction projects that require the use of large metal panels, such as in steel framing or prefabricated buildings, this vacuum lifter helps workers easily move materials on-site.

Warehousing and Logistics: For moving large metal plates, including those used for packaging, storage, and distribution, this vacuum lifter provides an efficient way to handle heavy materials without the need for forklifts or cranes.

6. Advanced Safety Features

Safety is a key consideration when lifting heavy materials, and this vacuum lifter is designed with multiple safety features to protect both the operator and the materials being lifted:

Vacuum Pressure Monitoring: The lifter includes an automatic vacuum monitoring system that ensures the vacuum level stays at a safe level throughout the lifting process. If the vacuum pressure drops below a safe threshold, the system will alert the operator with an audible or visual warning.

Automatic Locking Mechanism: Once the metal plate is lifted, the suction pads automatically lock into place to prevent accidental detachment during transport.

Emergency Stop Function: In case of any malfunction or emergency, the emergency stop button allows the operator to quickly stop the lifting process, ensuring safety and preventing accidents.

Non-Slip Suction Cups: The vacuum pads are made of high-quality, non-slip materials that provide a secure hold, ensuring the metal plate remains safely attached during movement.

7. Cost-Effective and Energy-Efficient

The DC12V rechargeable battery system makes this vacuum lifter energy-efficient and cost-effective. Unlike pneumatic lifters that require compressed air, or traditional electric lifters that require constant access to a power supply, this battery-operated system provides flexibility and efficiency at a lower operational cost. The rechargeable battery eliminates the need for additional infrastructure like compressors or expensive air supply systems, lowering both capital and operational expenditures.

Low Operating Costs: The lifter’s energy-efficient design helps reduce electricity consumption, making it an ideal solution for businesses looking to reduce their carbon footprint and energy expenses.

Long Battery Life: The battery is designed for long-lasting performance, supporting continuous use during busy shifts without requiring frequent recharging, increasing overall productivity.

8. Low Maintenance and Durability

The Metal Sheet Vacuum Lifter for Heavy Large-Format Sheet Metal is built for long-lasting durability with minimal maintenance requirements. The lifter features high-quality components designed to withstand the demanding environments of industrial settings. The vacuum system is durable, and the suction pads are made of long-lasting materials that can endure constant use.

Routine maintenance involves checking the vacuum pressure and inspecting the battery and suction pads. These simple tasks ensure that the vacuum lifter continues to operate efficiently without costly downtime or repairs.

Applications of the Metal Sheet Vacuum Lifter for Heavy Large-Format Sheet Metal

The 2,000kg Metal Sheet Vacuum Lifter is ideal for industries that need to handle heavy metal plates. Some of the primary applications include:

Metalworking: Used in metal fabrication shops to lift steel plates, aluminum sheets, and other metal materials for cutting, welding, or bending.

Automotive Manufacturing: Handling large panels and components for vehicle body assembly.

Construction: Moving large metal panels for prefabricated construction or cladding installations.

Shipbuilding: Handling large sheets of metal used in the construction of ships and maritime structures.

Warehouse and Logistics: Used for moving and stacking large metal sheets in distribution centers.