Plug-In Vacuum Lifter for loading and unloading systems in Fiber Laser Cutting Machines is a specialized tool used to automate the handling of metal sheets during the laser cutting process. It simplifies the movement of metal sheets onto the cutting bed and removes finished parts after cutting, significantly enhancing productivity, reducing manual labor, and improving safety in industrial settings.

Key Features of Plug-In Vacuum Lifters for Fiber Laser Cutting Machines:

Electrical Power Source (AC220V/380V):

These lifters are powered by a consistent electrical source (typically AC 220V or 380V), offering continuous, uninterrupted operation without the need for recharging or compressed air. This makes them ideal for long shifts or high-production environments.

Multiple Suction Cups:

Equipped with 6 to 8 suction cups, which vary in size from 150mm to 200mm in diameter, these lifters provide strong and stable suction for handling heavy metal sheets.

Suction cups are strategically placed to optimize contact area with the sheet, ensuring a secure grip, even on large sheets.

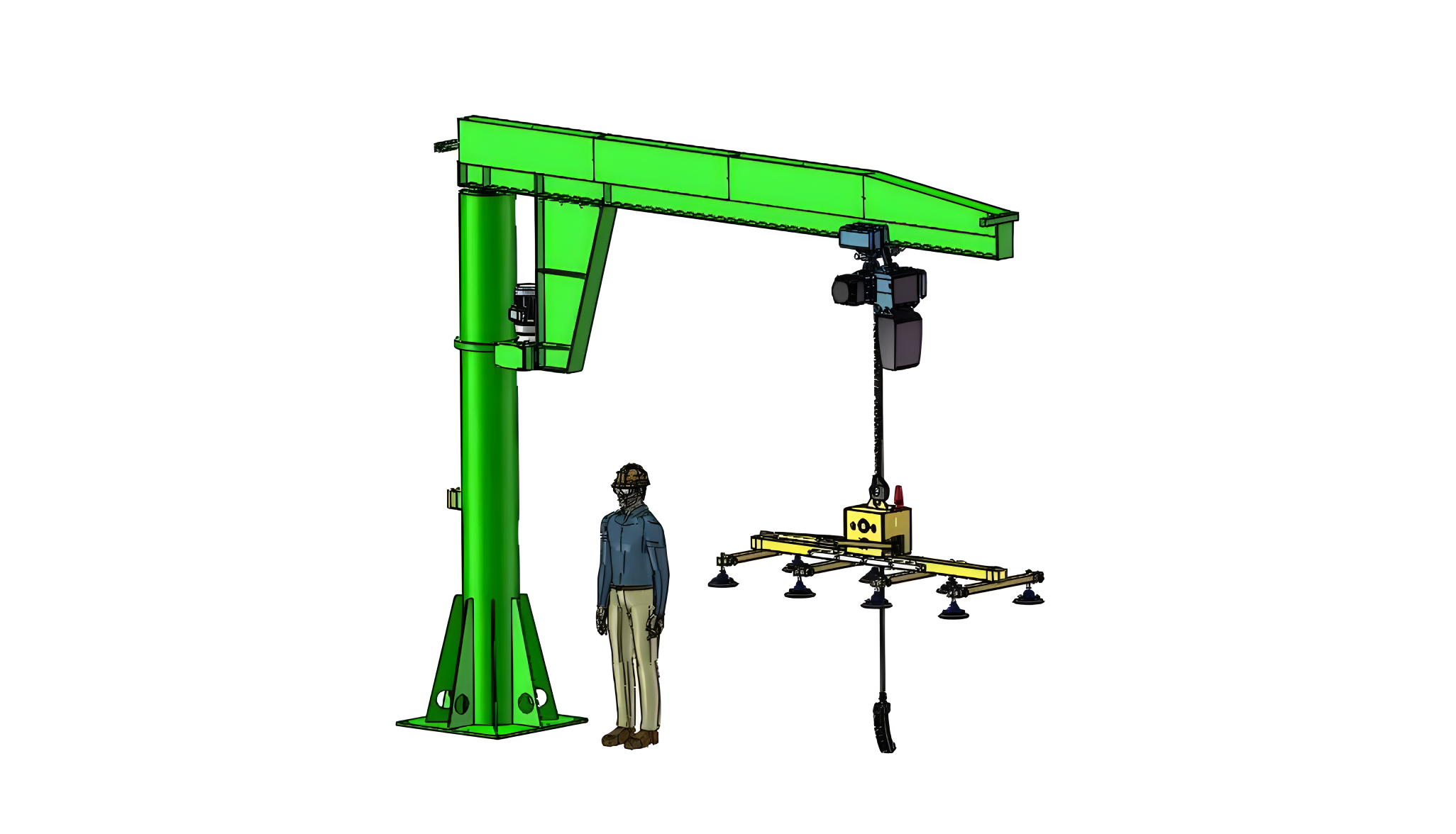

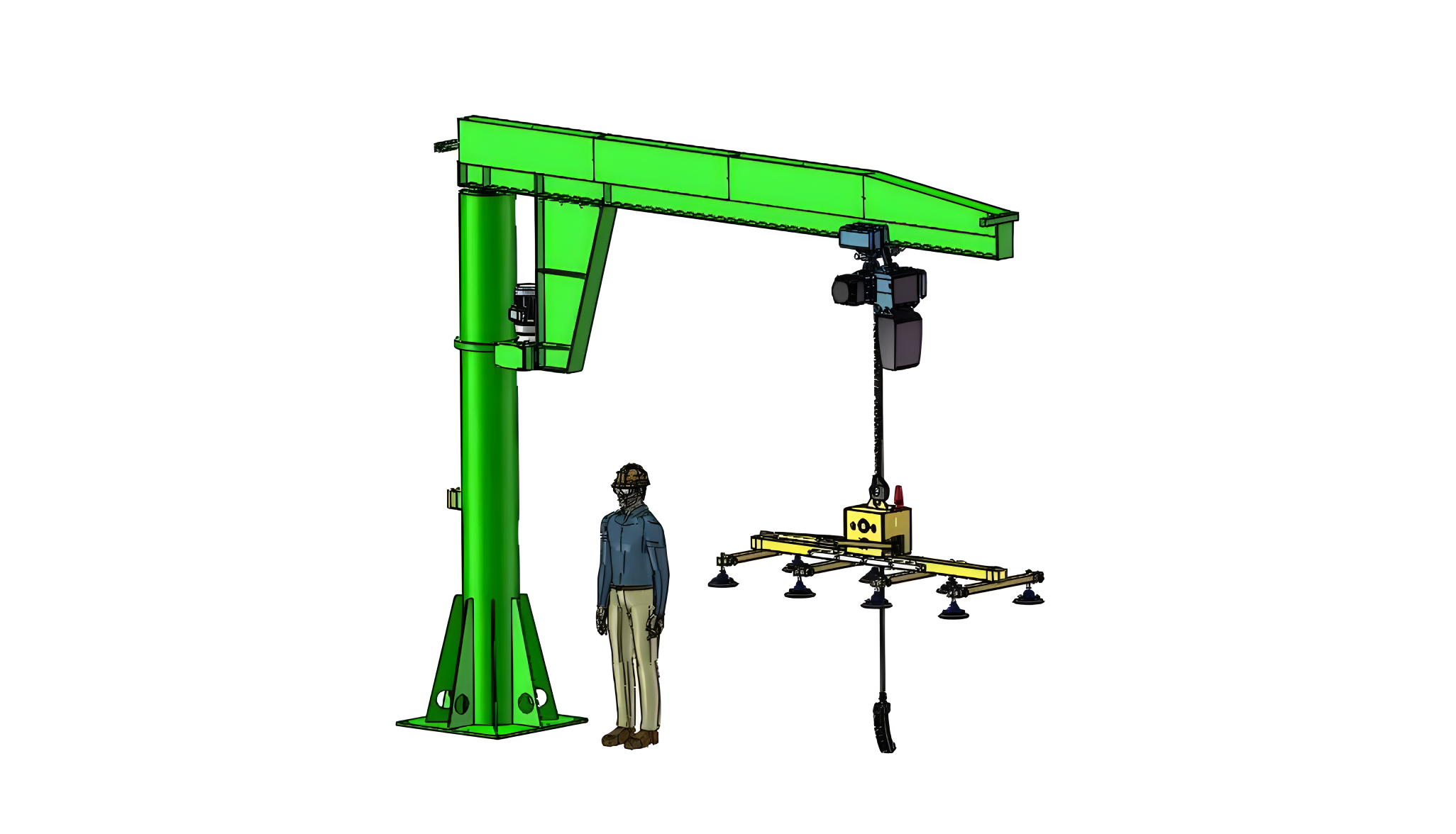

High Load Capacity:

Depending on the model, plug-in vacuum lifters can handle sheet loads ranging from 300 kg to 800 kg or more, making them suitable for lifting a wide variety of metal sheets, including those used in fiber laser cutting.

Sheet Size Compatibility:

Robust Construction:

The frame is designed for durability and stability, ensuring safe handling of large, heavy, and sometimes delicate metal sheets. Many models also come with features that allow for fine adjustments to handle sheets with different thicknesses and surface finishes.

Automatic and Manual Operation:

These systems often come with both manual and automatic operation modes. The automatic mode can synchronize with the fiber laser cutting machine’s workflow, loading raw materials and unloading finished pieces without operator intervention.

Operators can also manually control the vacuum lifter via remote control for more specialized handling, giving flexibility for diverse tasks.

360-Degree Rotation and Tilt Functionality:

Integration with Fiber Laser Cutting Systems:

These lifters are designed to integrate seamlessly with the automated workflow of fiber laser cutting machines, optimizing loading/unloading cycles, reducing machine downtime, and improving overall production efficiency.

Safety Features:

Plug-in vacuum lifters are equipped with vacuum sensors that constantly monitor suction levels, ensuring a strong hold on the metal sheet during transport.

In case of a power failure, anti-drop mechanisms are in place to safely lower the sheet, preventing accidents and damage.

Customizable Features:

Many plug-in vacuum lifters allow customization of suction cup configuration, sheet size capacity, and load-bearing capacity, making them adaptable for specific operational needs.

Applications:

Laser Cutting Machines:

Metal Sheet Processing:

In addition to laser cutting, these lifters can be used in other sheet metal processing operations such as stamping, bending, or punching, where frequent loading and unloading of metal sheets are required.

Manufacturing and Fabrication:

Widely used in industries like automotive, aerospace, appliance manufacturing, and general metal fabrication where precision and efficiency in material handling are essential.

Advantages:

Continuous Operation:

Improved Safety:

Reduces the risk of injury related to manual lifting of large, heavy, or sharp-edged metal sheets.

Vacuum sensors and anti-drop mechanisms add a layer of safety, ensuring secure handling at all times.

Increased Production Efficiency:

Versatility:

Can handle a variety of sheet sizes, thicknesses, and materials such as carbon steel, stainless steel, aluminum, and more. It is suitable for both ferrous and non-ferrous metals.

Precision and Control:

Typical Specifications:

Load Capacity: 300 kg to 800 kg (or more)

Power Supply: AC220V/380V

Suction Cup Diameter: 150-200mm

Number of Suction Cups: 6 to 8

Sheet Size Range: 2000mm × 1000mm to 4000mm × 2000mm

Vacuum Pressure: Adjustable depending on material and sheet thickness

Rotation/Tilting Mechanism: Optional, depending on the model

Recommended Models:

Several manufacturers produce high-quality plug-in vacuum lifters for fiber laser cutting machines. Notable manufacturers include:

Schmalz

ANVER

Vaculex

GGR Group

These manufacturers offer different models tailored to specific needs, from basic models for small-scale operations to advanced systems designed for large, heavy-duty industrial applications.

Safety Considerations:

Regular Maintenance:

Training for Operators:

Emergency Stop:

Conclusion:

A Plug-In Vacuum Lifter for loading and unloading fiber laser cutting machines is a valuable investment for businesses looking to increase efficiency, reduce labor costs, and enhance safety in their metal sheet handling processes. By automating material handling, these lifters can help companies optimize their cutting processes and improve overall production throughput.

Pneumatic Vacuum Lifter

| Product Model | JS-300-2M/3M |

| Rated Load (kg) | 300 |

| Suction Cup Diameter (mm) | 150 |

| Number of Suction Cups | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 |

| Working Voltage | 0.8 MPa Air Supply |

Battery-Powered Vacuum Lifter

| Product Model | JS-JG300-2M/3M | JS-JG600-2M/3M | JS-JG800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 150 | 150 |

| Number of Suction Cups | 8 | 6 | 6 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Working Voltage | DC12V | DC12V | DC12V |

Plug-In Vacuum Lifter

| Product Model | JS-GC300-2M/3M | JS-GC600-2M/3M | JS-GC800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 8 | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Working Voltage | AC220V/380V | AC220V/380V | AC220V/380V |