Precision Laser Cutting Services for Frameless SMT Stencils

In the ever-evolving world of electronics manufacturing, precision, efficiency, and cost-effectiveness are essential. Our Precision Laser Cutting Services for Frameless SMT Stencils deliver exactly that—premium-quality stencils designed specifically for use with stencil tensioning systems, also known as Reusable Stencil Frames (such as the popular Wizard Frame). These frameless stencils are a versatile and economical solution for PCB assembly operations, offering excellent performance in prototype development and short production runs.

With a focus on laser precision, material integrity, and flexible applications, our frameless SMT stencils help streamline your manufacturing process, reduce overall production costs, and deliver consistently superior results.

Applications

Our Frameless SMT Stencils are engineered for a variety of PCB assembly scenarios, providing outstanding utility in the following areas:

Prototype PCB Assembly: Ideal for engineering builds, prototypes, and pre-production testing where quick setup and changeover are essential.

Short Production Runs: Perfect for low- to medium-volume production, especially when flexibility and cost-efficiency are critical.

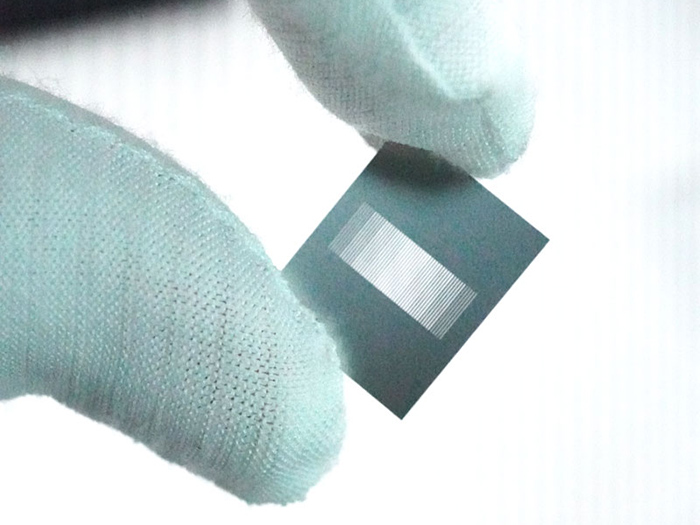

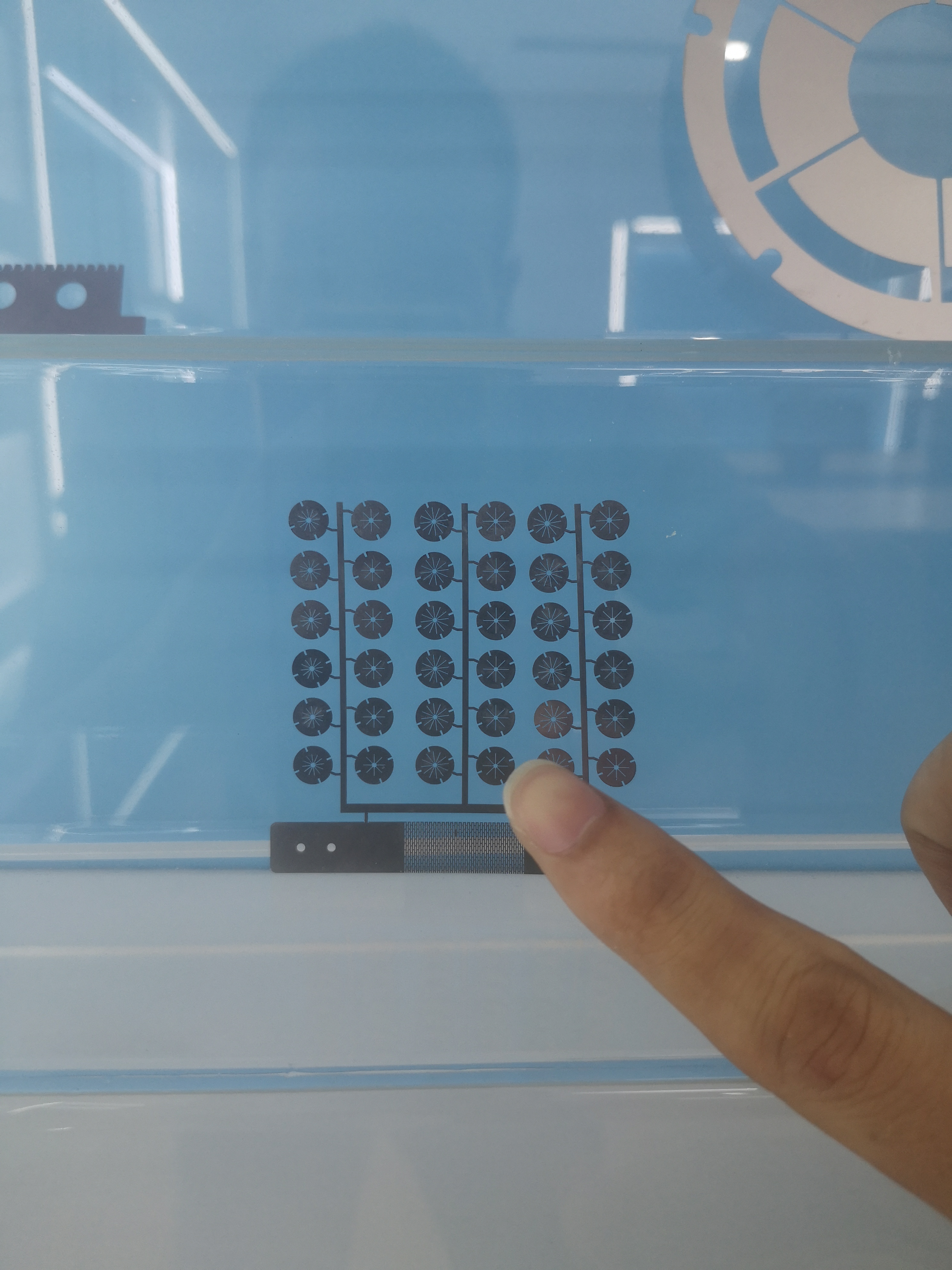

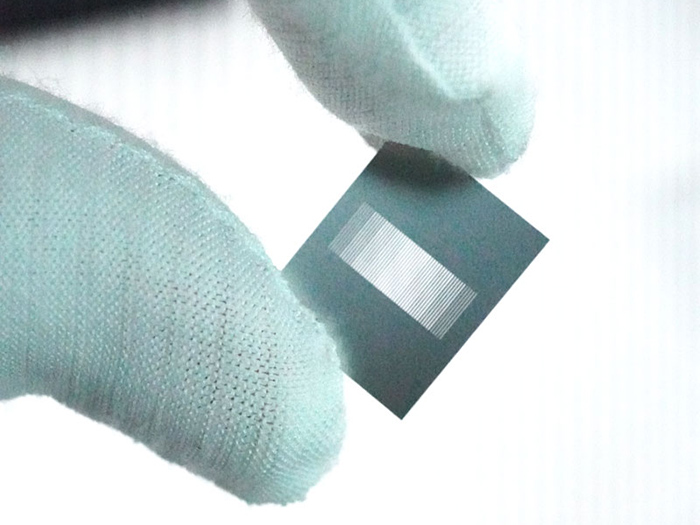

High-Precision Applications: Designed to support fine-pitch components (16 mil pitch and smaller) and Micro BGA assemblies, where accuracy and clean aperture walls are mandatory.

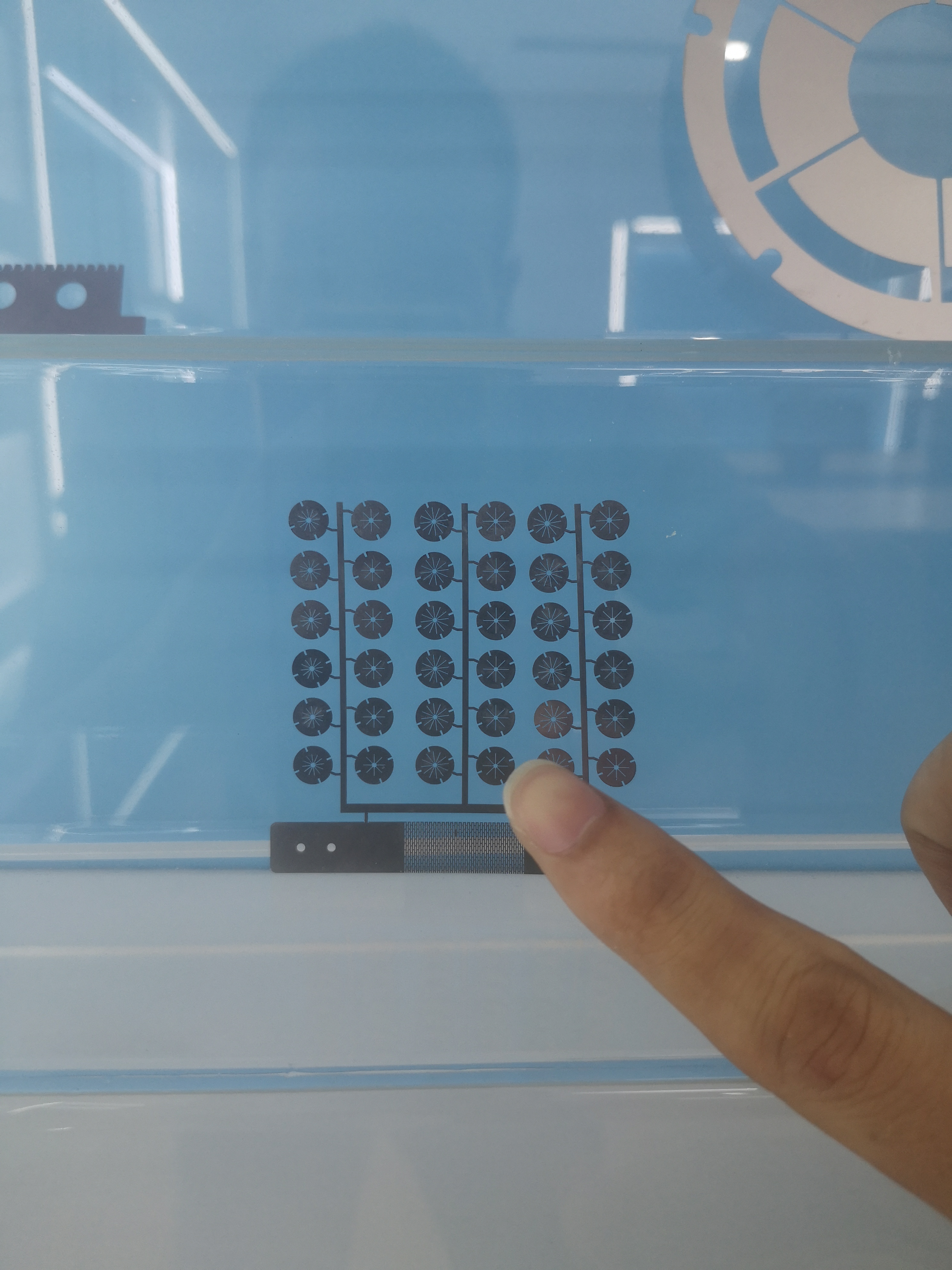

Panelized PCB Assembly: Supports panelized designs, allowing multiple boards to be printed simultaneously, enhancing throughput and assembly efficiency.

Rework and Repair Operations: In conjunction with a tensioning system, frameless stencils can also be used for selective rework applications where targeted solder paste deposition is needed.

Service Features

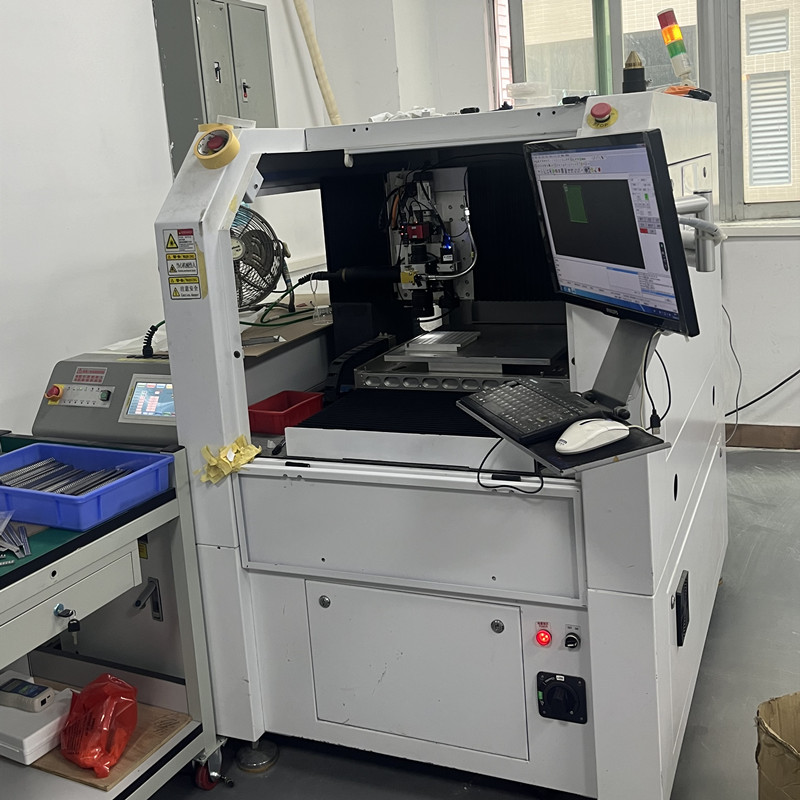

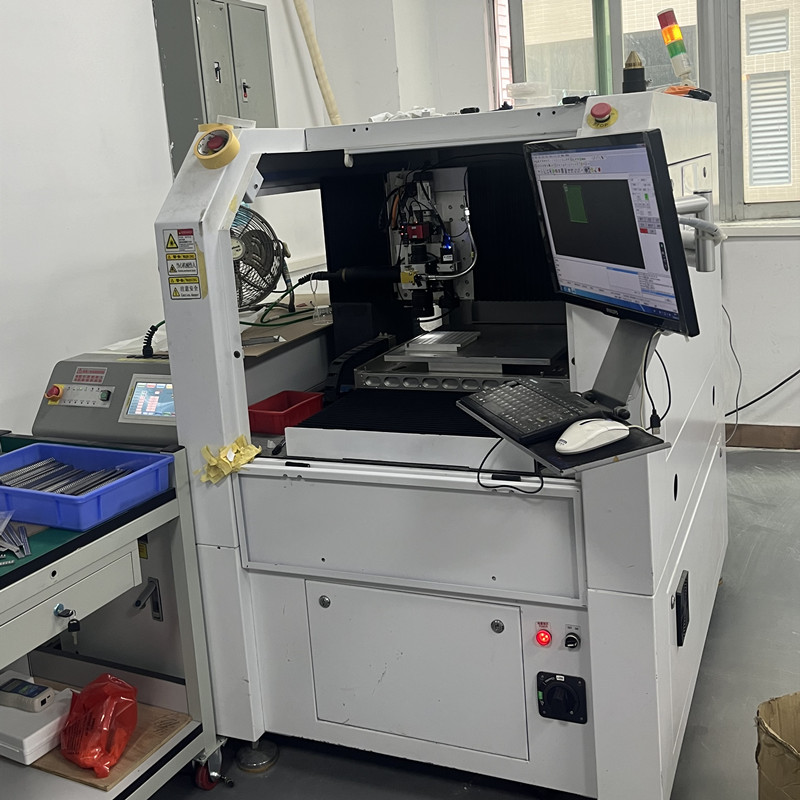

1. 100% Laser Cutting Technology

All of our frameless SMT stencils are manufactured exclusively using state-of-the-art laser cutting machines.

This ensures:

Ultra-smooth, burr-free aperture walls

High precision and repeatability

Superior solder paste release characteristics

Long stencil lifespan with consistent performance

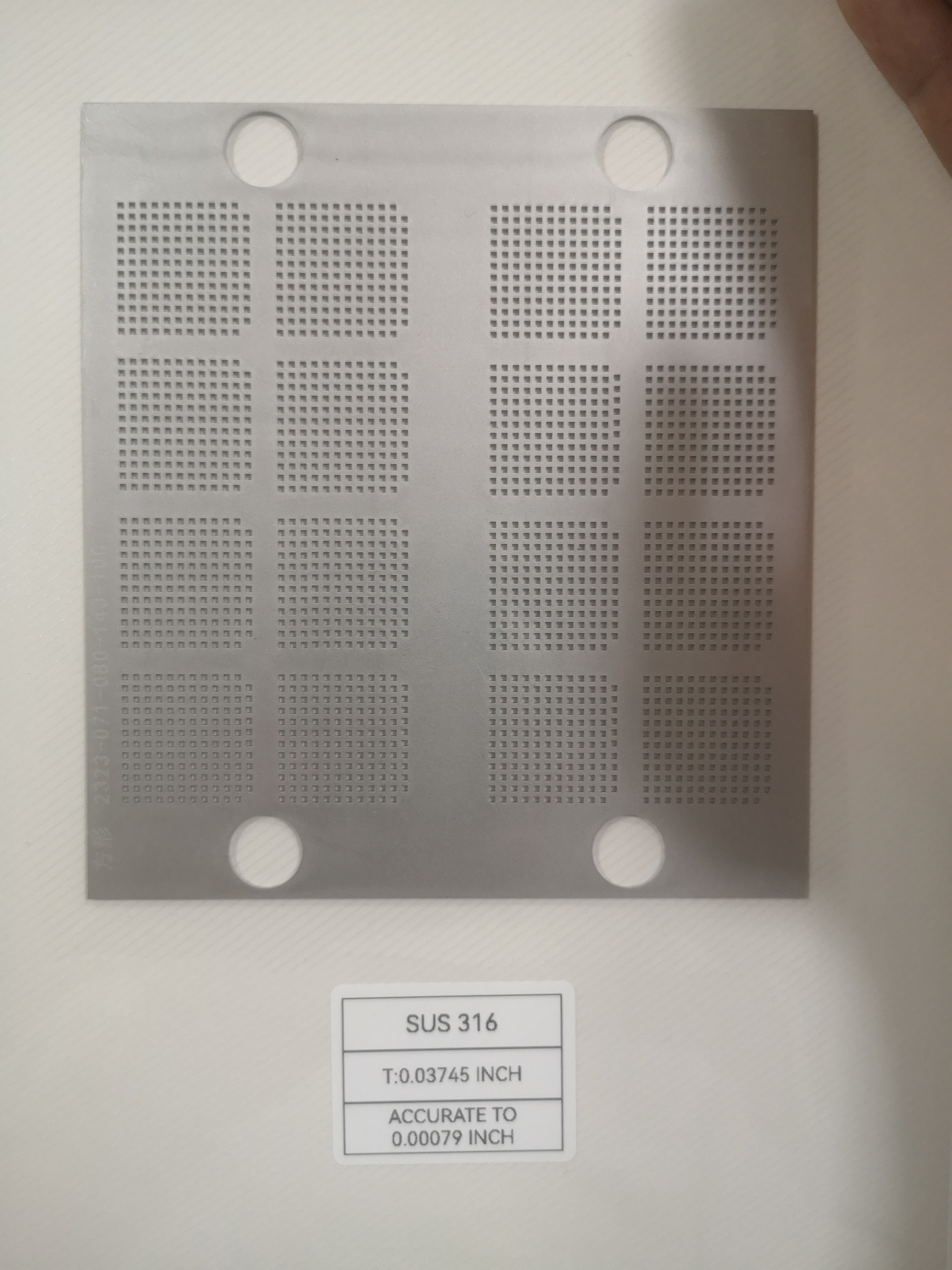

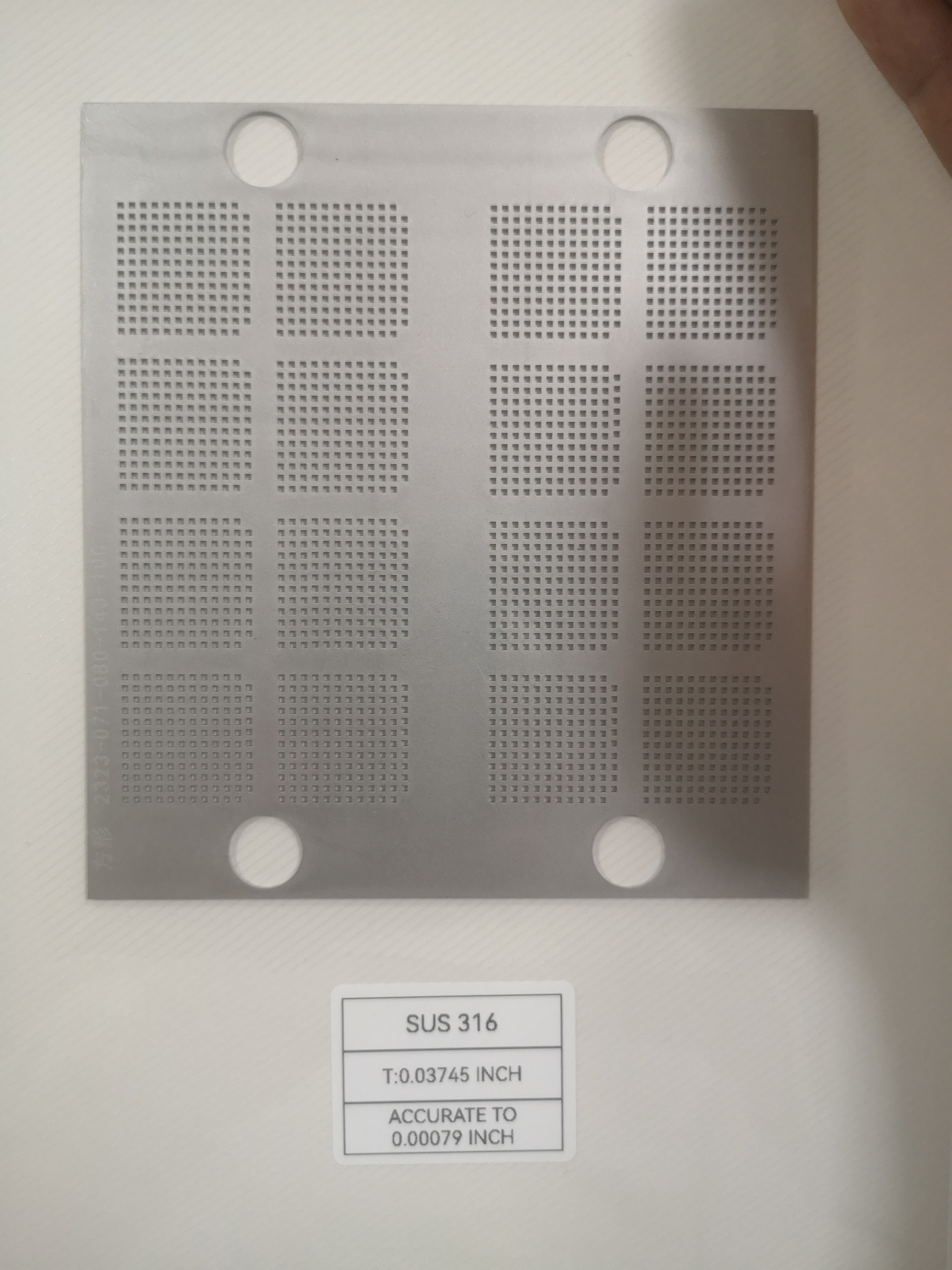

2. Premium Stainless Steel Material

We use high-grade stainless steel for all stencils, providing:

Exceptional durability and resistance to wear

Reliable flatness and stability during printing

Compatibility with fine-pitch and complex designs

3. Flexible Thickness Options

Stencil thicknesses are available from .002 inches to .016 inches, allowing you to tailor the stencil to your specific solder paste volume and component requirements.

4. High-Precision Apertures

Minimum cut width: .002 inches

Aperture tolerance: Within .00025 inches These specifications allow us to deliver stencils that meet the most demanding precision requirements for today’s miniaturized components.

5. Large Stencil Size Support

6. Support for Fiducial and Panelized Data

We support both fiducial marks and panelized layouts, ensuring that your stencil will align perfectly during the solder paste printing process, resulting in higher assembly yields.

7. Space-Saving and Cost-Efficient

Frameless stencils require significantly less storage space than framed stencils, helping you manage inventory more efficiently.

They are considerably more affordable than permanently framed stencils, especially when factoring in the reuse of tensioning frames across multiple builds.

Why Choose Frameless SMT Stencils?

Choosing frameless SMT stencils manufactured with precision laser cutting offers a series of tangible benefits:

Cost Savings

Frameless stencils typically cost less than framed options, making them ideal for prototypes, pre-production, and short runs.

Reusable tensioning frames eliminate the need for a separate frame per stencil, reducing your tooling costs over time.

Flexibility and Versatility

High-Quality Solder Printing

Laser-cut stencils produce superior solder paste deposition, reducing defects such as insufficient solder, bridging, and tombstoning.

Smooth aperture walls enhance paste release and maintain consistent print quality throughout the stencil’s life.

Storage and Handling Advantages

Frameless stencils are lighter and more compact, making them easier to store, transport, and handle compared to traditional framed stencils.

Handling aids, such as optional flaps, are available to make stencil loading and unloading even easier.

Technical Specifications

| Feature | Specification |

| Technology Used | 100% Laser Cutting |

| Material | Stainless Steel |

| Stencil Thickness | .002 - .016 Inches |

| Minimum Cut Width | .002 Inches |

| Maximum Size | 29” x 29” |

| Aperture Tolerance | Within .00025 Inches |

| Supports Fiducial Data | Yes |

| Supports Panelized Data | Yes |

Quality Assurance

Each stencil undergoes a stringent quality inspection process to ensure that it meets our exacting standards.

Our quality control measures include:

Dimensional Verification: Confirming aperture sizes and locations match the customer's CAD data.

Visual Inspection: Checking for burrs, scratches, and imperfections.

Material Testing: Ensuring consistent thickness and flatness.