✅ RRP5340 Wet Wide Belt Sander | 3-Station | PLC Touch Screen Control | Non-Magnetic Conveyor

Product Introduction:

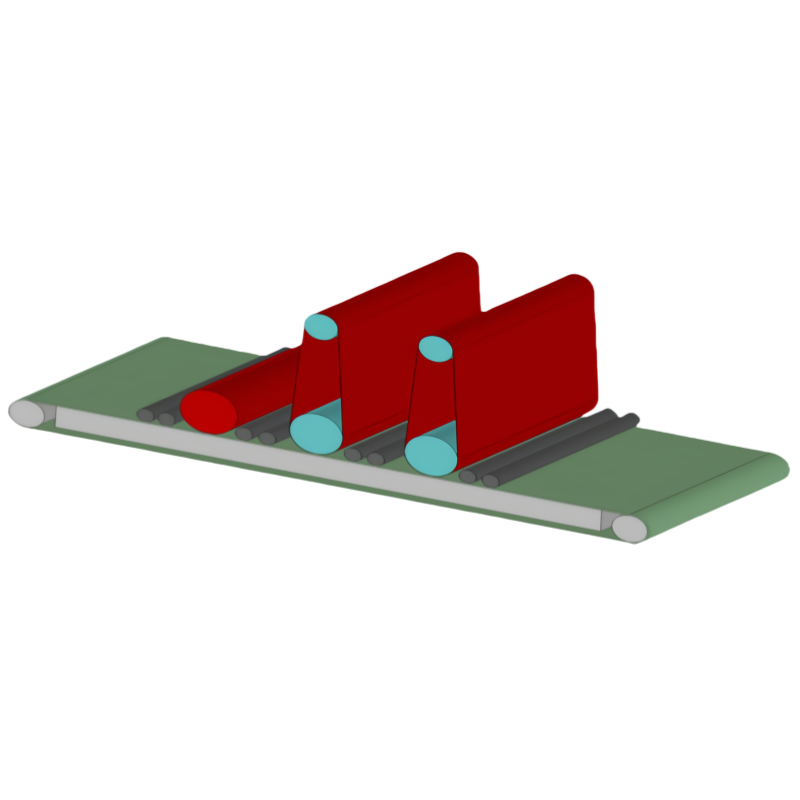

The RRP5340 Wet Wide Belt Sander is a high-performance, industrial-grade machine specifically engineered for surface grinding, deburring, oxide removal, and fine finishing of metal sheets and components. Featuring two abrasive belt heads and one brush head, this model is designed to efficiently handle heat-sensitive materials such as stainless steel, aluminum, thin sheets, and mixed materials.

Operating within a wet processing system, the machine minimizes heat buildup, prevents material warping, and ensures dust-free operation, while significantly extending the life of abrasive consumables. The PLC touch screen control panel provides a user-friendly interface for easy operation, precise adjustment, and real-time monitoring, making it ideal for both experienced operators and newcomers to industrial finishing processes.

Unlike magnetic table models, the RRP5340 uses a standard non-magnetic conveyor system, making it suitable for non-ferrous metals and parts of various shapes and sizes that do not require magnetic fixation.

✅ Key Features:

✅ Three Processing Stations: Includes two sanding heads and one brush head to complete deburring, edge rounding, oxide removal, and surface finishing in a single pass.

✅ Wet Processing System: Integrated water cooling keeps materials cool, prevents overheating, and reduces airborne dust.

✅ Standard Conveyor (Non-Magnetic): Suitable for both ferrous and non-ferrous materials, allowing flexibility in processing various metals like stainless steel, aluminum, and copper.

✅ PLC Touch Screen Control: Simplifies operation with recipe saving, quick adjustment, and real-time error diagnostics.

✅ 400mm Working Width: Perfect for medium-sized metal parts, offering flexibility for different industries.

✅ Durable Industrial Design: Heavy-duty welded frame ensures high stability, minimal vibration, and consistent performance.

✅ Efficient Edge Rounding & Fine Finishing: The combination of sanding belts and a brush head ensures high-quality surface finishing and smooth edge rounding.

✅ Energy-Efficient Motors: Optimized motor configuration reduces energy consumption while maintaining high productivity.

✅ Machine Functions:

✅ Deburring: Removes burrs and sharp edges from laser-cut, punched, or plasma-cut metal parts.

✅ Slag & Dross Removal: Effectively removes slag from flame and plasma-cut components.

✅ Oxide Removal: Cleans oxide layers, improving weldability and coating adhesion.

✅ Edge Rounding: Creates a uniform radius on sharp edges to improve safety and paint durability.

✅ Surface Conditioning & Graining: Achieves consistent, fine grain finishes like hairline or satin polish on stainless steel, aluminum, and other alloys.

✅ Cooling & Dust Control: Wet process ensures no heat-induced distortion and minimal airborne contaminants.

✅ Technical Specifications:

| Parameter | Specification |

| Model | RRP5340 |

| Max Working Width | 400 mm |

| Max Working Thickness | 60 mm |

| Min Working Length | 150 mm |

| Sanding Stations | 3 (2 sanding heads + 1 brush head) |

| Abrasive Belt Size | 1900 mm x 400 mm |

| First Sanding Head Power | 7.5 kW |

| Second Sanding Head Power | 7.5 kW |

| Brush Head Power | 5.5 kW |

| Conveyor Motor Power | 1.5 kW |

| Lifting Motor Power | 0.37 kW |

| Total Power | ~22.5 kW |

| Conveyor Speed | Adjustable, 0.5 – 6 m/min |

| Sanding Belt Speed | 12 m/s |

| Cooling System | Water circulation with filtering |

| Control System | PLC Touch Screen |

| Conveyor Type | Non-Magnetic Conveyor Belt |

| Machine Dimensions (L×W×H) | 2500 × 1500 × 1900 mm |

| Net Weight | ~2000 kg |

✅ Application Scenarios:

✅ Laser Cutting Parts Deburring

✅ Flame/Plasma Cut Parts Slag Removal

✅ Oxide Layer Removal before Welding

✅ Edge Rounding for Safer Handling and Better Coating

✅ Surface Polishing and Graining

✅ Finishing Thin Stainless Steel Panels

✅ Aluminum and Copper Sheet Finishing

✅ Sanitaryware, Kitchenware, and Appliance Manufacturing

✅ Automotive Metal Component Processing

✅ Industries Served:

Sheet Metal Fabrication

Laser and Plasma Cutting Workshops

Kitchenware Production

Automotive Parts Manufacturing

Elevator Panel Fabrication

Sanitary Product Factories

Metal Processing Service Providers

✅ Advantages of the RRP5340:

✅ One-Pass Operation: Multiple processes in a single feed reduce labor costs and increase output.

✅ Heat-Free Processing: Wet method prevents warping or discoloration of thin, delicate parts.

✅ Cost Savings: Extended abrasive lifespan and minimized rework improve operational cost-effectiveness.

✅ Easy Operation: PLC control reduces the learning curve and enhances process stability.

✅ Versatile Material Compatibility: Processes ferrous and non-ferrous metals without magnetic limitations.

✅ Safe, Clean Working Environment: Wet grinding captures dust and minimizes heat exposure.

✅ Summary:

The RRP5340 Wet Wide Belt Sander with a non-magnetic conveyor is the optimal choice for manufacturers seeking efficient, high-quality deburring, oxide removal, and surface finishing, especially when processing mixed materials or non-magnetic metals. It offers exceptional precision, durability, and productivity, making it a core asset for modern metal fabrication lines.