✅ RRR5340C Automatic Wet Wide Belt Sander | Magnetic Conveyor Table | 3 Sanding Heads | PLC Touch Screen

Product Overview: RRR5240C 400mm 3-Head Wide Belt Wet Grinding & Finishing Machine

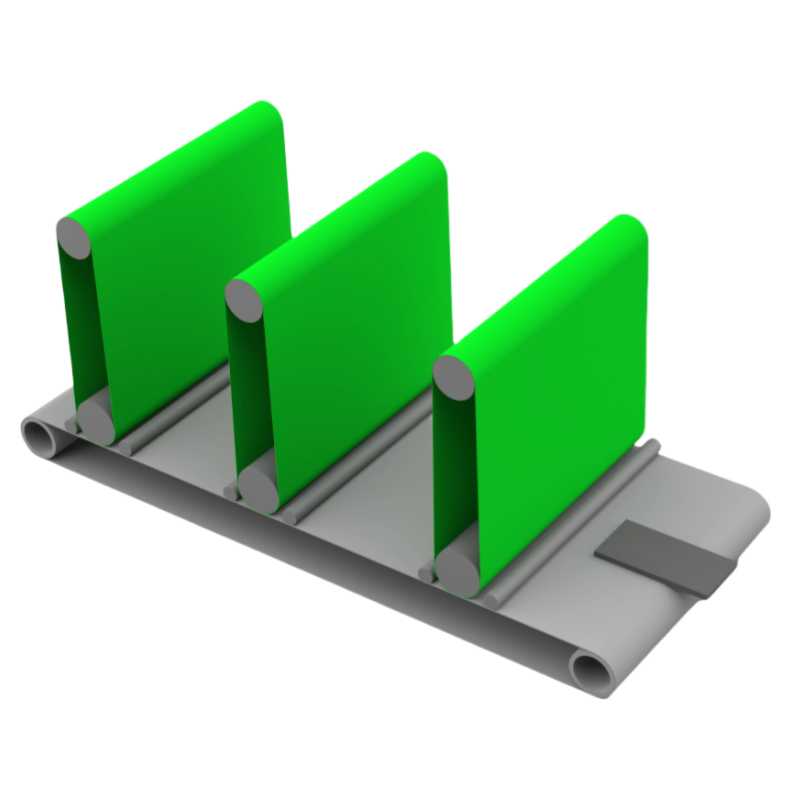

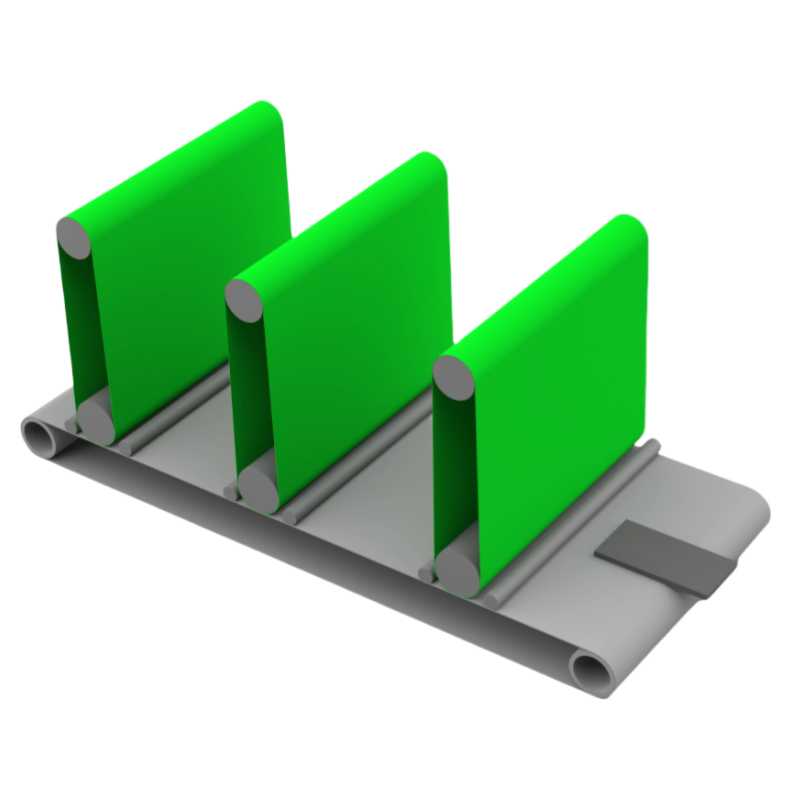

The Model RRR5240C is an industrial-grade, three-head, wide-belt grinding machine engineered for unparalleled efficiency in wet grinding, deburring, and surface finishing of metal sheets. This heavy-duty workhorse is specifically designed to handle the demanding requirements of post-processing laser-cut, plasma-cut, and punched components, delivering a superior, consistent satin finish on stainless steel and other metals. Its advanced three-station design allows for a complete roughing to finishing sequence in a single pass, dramatically boosting productivity.

Key Features & Competitive Advantages

Triple Sanding Head Configuration: The core of its superiority. Three powerful independent sanding heads can be configured with a progression of abrasive grits (e.g., coarse, medium, fine) to achieve a perfect finish from a raw, burred part in just one pass. This eliminates the need for multiple machines or manual intermediate steps.

Magnetic Conveyor System (Standard): Ensures positive hold-down of ferrous metals, especially stainless steel sheets. This prevents vibration, minimizes chatter marks, and guarantees flat, consistent pressure across the entire workpiece for a perfectly even finish without the part lifting or shifting.

Advanced PLC Touch Screen Control: Provides effortless and precise control over all machine functions. Operators can easily set and save recipes for different materials and finishes, adjust conveyor speed, monitor system status, and troubleshoot, ensuring repeatability and reducing operator error.

High-Power Grinding Efficiency: With a massive total of 22.5 kW (3 x 7.5 kW) of grinding power, the machine can aggressively remove heavy laser scale, thick burrs, and heat tint without stalling, while maintaining high throughput.

Superior Wet Process Technology: The closed-loop water cooling and filtration system is essential for quality finishing. It prevents heat buildup (avoiding material warping or property changes), extends abrasive belt life, suppresses dust completely, and ensures a scratch-free, high-luster satin finish.

Robust Construction: Weighing approximately 2200 kg, the machine features a rigid frame that absorbs vibrations, ensuring stability during operation and contributing to exceptional finish quality and machine longevity.

Technical Specifications: Model RRR5240C

| Parameter | Specification |

| Model | RRR5240C |

| Max Working Width | 400 mm |

| Max Working Thickness | 60 mm |

| Min Working Length | 150 mm |

| Number of Sanding Heads | 3 |

| Sanding Belt Size | 1900 mm × 400 mm |

| Power - 1st Sanding Head | 7.5 kW |

| Power - 2nd Sanding Head | 7.5 kW |

| Power - 3rd Sanding Head | 7.5 kW |

| Power - Conveyor Motor | 1.5 kW |

| Power - Lifting Motor | 0.37 kW |

| Total Installed Power | ~24 kW |

| Conveyor Speed (Variable) | 0.5 – 6 m/min |

| Abrasive Belt Speed | 12 m/s |

| Cooling System | Water circulation with integrated filtration |

| Control System | PLC with Touch Screen Interface |

| Worktable Type | Magnetic Conveyor (Standard) |

| Machine Dimensions (L×W×H) | 2600 mm × 1500 mm × 1900 mm |

| Machine Weight | ~2200 kg |

Applications

This machine is the ultimate solution for:

Heavy-Duty Deburring: Efficiently removing large burrs from thermally cut parts.

Descaling & Heat Tint Removal: Completely eliminating the heat-affected zone (HAZ) and discoloration from laser and plasma cutting on stainless steel.

Surface Finishing: Producing uniform brushed, satin, or hairline finishes on stainless steel, aluminum, brass, and carbon steel.

Surface Leveling: Smoothing out imperfections and creating a perfectly flat surface on sheet metal.

Ideal For Industries:

Precision metal fabrication shops

Laser cutting and profiling service bureaus

Kitchen equipment and appliance manufacturing

Architectural metalwork and decoration (elevators, cladding, signage)

Automotive and aerospace component suppliers

Summary

The RRR5240C represents the pinnacle of automated wide-belt finishing technology. Its robust three-head design, standard magnetic conveyor, and intelligent PLC control make it a premium choice for high-volume manufacturers who require maximum throughput, exceptional finish quality, and operational simplicity. It is more than just a grinder; it is a complete finishing solution designed to integrate seamlessly into modern production lines and deliver a rapid return on investment.