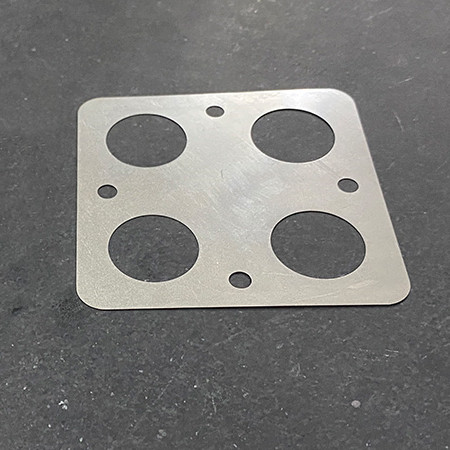

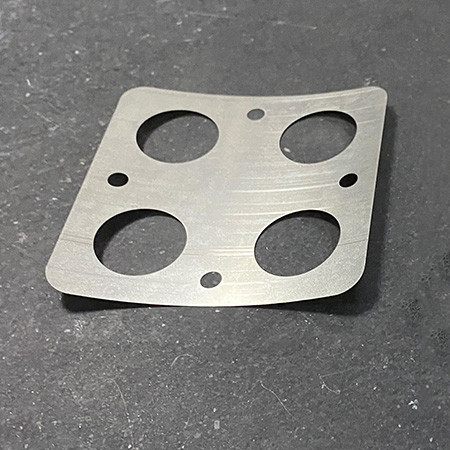

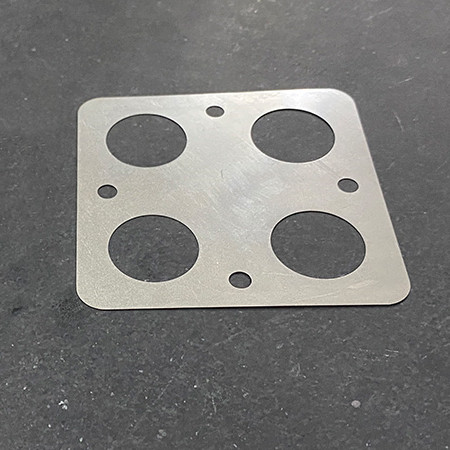

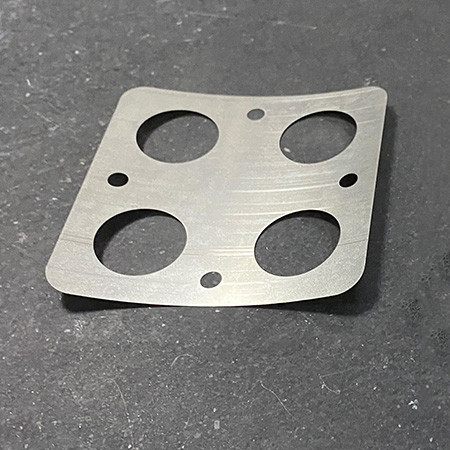

Sheet Metal Leveling Machines for Light Laser and Stamped Parts

These Sheet Metal Leveling Machines are designed for leveling light laser-cut, plasma-cut, and stamped parts with a sheet metal thickness ranging from 0.8mm to 4mm. Equipped with advanced features, these machines provide superior precision, efficiency, and consistency in leveling thin and medium thickness metal sheets, making them ideal for high-precision applications in various industries.

Key Specifications:

Width: 200-2200mm

Roll Diameter: 50mm

Rated Thickness: 0.8-4mm

Number of Rolls: 21 (Upper: 10, Lower: 11)

Leveling Roller Gap Adjustment: Four-point automatic adjustment, driven by servo motors

| Model | STR-20CNC | STR-30CNC | STR-40CNC | STR-50CNC |

| Width (mm) | 200-1300 | 200-2200 | 400-2200 | 400-2200 |

| Roll Diameter (mm) | 20 | 30 | 40 | 50 |

| Rated Thickness (mm) | 0.2-1.5 | 0.5-2.5 | 0.6-3 | 0.8-4 |

| Maximum Thickness (mm) | 1.5 | 2.5 | 3 | 4 |

| Number of Rolls | 23 (Upper: 11, Lower: 12) | 21 (Upper: 10, Lower: 11) | 21 (Upper: 10, Lower: 11) | 21 (Upper: 10, Lower: 11) |

| Shortest Part (mm) | 10x40 | 10x60 | 10x75 | 15x100 |

| Leveling Speed (m/min) | 0-12 | 0-12 | 0-12 | 0-12 |

| Leveling Roller Gap Adjustment | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors |

| Voltage | 3-phase 380V | 3-phase 380V | 3-phase 380V | 3-phase 380V |

Applications:

These leveling machines are ideal for a wide range of light metal parts that have undergone laser cutting, plasma cutting, or stamping. Some key applications include:

Laser-Cut Parts: Post-processing to correct warping or distortion from laser cutting, providing a flat, even surface.

Plasma-Cut Parts: Flattening plasma-cut parts for improved dimensional accuracy and quality.

Stamped Parts: Leveling stamped metal parts, ensuring they are ready for further processing like welding, painting, or assembly.

Industries:

Automotive Manufacturing: Ensures flatness and dimensional precision for automotive components.

Electronics: Ideal for leveling metal parts used in electronic devices, ensuring the parts fit together properly without distortion.

Appliance Manufacturing: Corrects warping in metal sheets used for home appliances, improving both the aesthetics and functionality of the final products.

Construction and HVAC: Leveling metal sheets used in construction materials and HVAC systems to ensure precise fitting and smooth surfaces.

Benefits:

Improved Flatness: The machine ensures consistent flatness across all parts, improving the quality of the end product and reducing the need for rework.

Increased Production Efficiency: The automatic gap adjustment and high-level automation increase throughput, reduce manual labor, and shorten cycle times, making the process more efficient and cost-effective.

Minimized Material Waste: By providing consistent and precise leveling, the machine minimizes material waste due to misalignment or distortion, improving the overall cost-effectiveness of production.

Consistent Quality: With the ability to process a wide range of material thicknesses, the machine ensures that dimensional accuracy and surface quality are consistently maintained throughout the production process.