100T 3200mm CNC Hydraulic Double Servo Press Brake – Servo CNC Oil-Electro Hybrid Hydraulic Press Brake

The 100T 3200mm CNC Hydraulic Double Servo Press Brake is an advanced servo CNC oil-electric hybrid press brake designed to provide high performance, energy efficiency, and precision for bending sheet metal. With a 100-ton bending force and 3200 mm bending length, this machine is capable of handling medium to large-sized metal sheets, offering excellent versatility and precision for various industrial applications. The integration of servo-electric technology with traditional hydraulic power delivers outstanding energy savings while maintaining optimal force control.

This CNC Hybrid Press Brake is suitable for industries such as automotive, aerospace, metal fabrication, and heavy machinery manufacturing, where high-quality bending operations are essential. The hybrid technology ensures reduced operational costs and higher productivity while maintaining the flexibility needed for bending a wide variety of materials.

Double Servo Electro-Hydraulic Hybrid Press Brake parameters:

| Parameter Name | Unit | WBL-40/1500 | WBL-100/2500 | WBL-100/3200 | WBL-100/4100 | WBL-160/3200 | WBL-160/4100 | WBL-200/3200 | WBL-200/4100 |

| Bending Force | kN | 400 | 1000 | 1000 | 1000 | 1600 | 1600 | 2000 | 2000 |

| Effective Bending Length | mm | 1500 | 2500 | 3200 | 4100 | 3200 | 4100 | 3200 | 4100 |

| Maximum Opening Height | mm | 400 | 460 | 460 | 460 | 460 | 460 | 500 | 500 |

| Column Distance | mm | 1140 | 2010 | 2700 | 3600 | 2700 | 3600 | 2700 | 3600 |

| Throat Depth | mm | 300 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Ram Stroke | mm | 160 | 200 | 200 | 200 | 200 | 200 | 240 | 240 |

| Fast Down Speed | mm/s | 240 | 240 | 240 | 240 | 200 | 200 | 200 | 200 |

| Working Speed | mm/s | 10-15 | 10-15 | 10-15 | 10-15 | 10-14 | 10-14 | 10-14 | 10-14 |

| Return Speed | mm/s | 220 | 220 | 220 | 220 | 200 | 200 | 200 | 200 |

| Motor Power | kW | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

| Oil Tank Capacity | L | 40*2 | 40*2 | 40*2 | 40*2 | 65*2 | 65*2 | 65*2 | 65*2 |

| Overall Dimensions | Length (mm) | 1700 | 2700 | 3400 | 4300 | 3500 | 4300 | 3500 | 4300 |

| Width (mm) | 1540 | 1600 | 1600 | 1600 | 1650 | 1650 | 1900 | 1900 |

| Height (mm) | 2350 | 2400 | 2500 | 2550 | 2630 | 2630 | 2750 | 2750 |

| Machine Weight | kg | 3800 | 7500 | 9800 | 11500 | 11800 | 13800 | 14700 | 16000 |

Key Features and Advantages

1. CNC Control System

The CNC control system is central to the 100T 3200mm CNC Hydraulic Double Servo Press Brake, offering precise control over every aspect of the bending operation:

Advanced CNC Software: The machine is equipped with a high-performance CNC control system that allows for easy programming of bend sequences, angles, material types, and sheet thicknesses. This ensures each part is bent to the required specifications with high precision.

Intuitive Touchscreen Interface: The touchscreen interface allows for quick input of parameters, making the machine easier to operate and reducing the chance for programming errors.

Multi-Axis Control: The CNC system controls multiple axes simultaneously, including the ram, backgauge, and other movements. This makes the press brake highly efficient and capable of producing parts with complex geometries and multi-bend requirements.

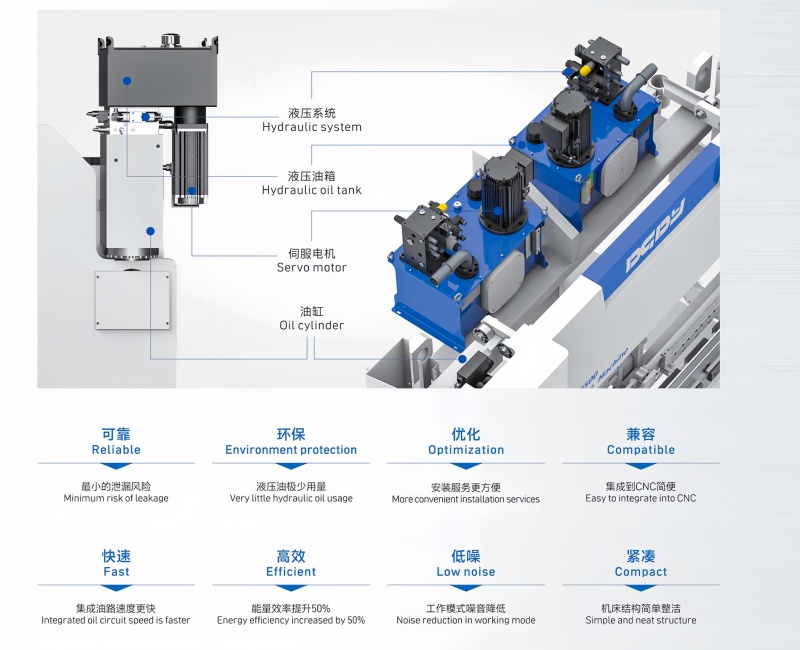

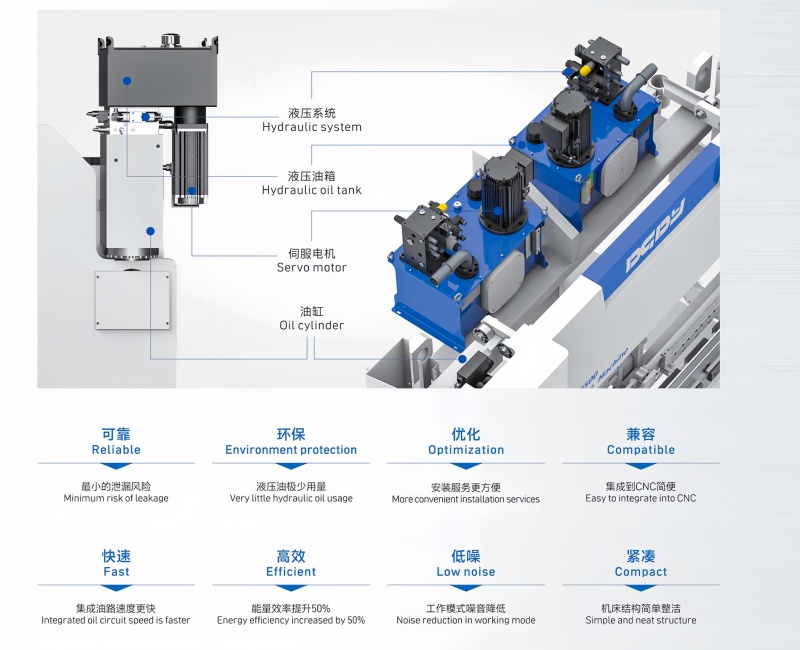

2. Hybrid Drive Technology (Servo-Electric + Hydraulic)

The hybrid drive system integrates both servo-electric and hydraulic technologies to optimize performance, energy efficiency, and precision:

Dual Servo Motors: The use of two servo motors for controlling the ram and backgauge axes allows for highly precise positioning and speed control. Servo motors are energy-efficient and use only the required power, reducing overall energy consumption compared to traditional hydraulic press brakes.

Hydraulic Support: The hydraulic system complements the servo motors, providing the additional force necessary for handling larger and thicker materials that require significant bending pressure. This hybrid design ensures the machine is capable of both high precision and high force.

Energy Efficiency: The servo motors drastically reduce energy consumption by only drawing power when needed, thus reducing electricity costs and improving the overall efficiency of the press brake. The energy-efficient design makes this machine environmentally friendly and more cost-effective over time.

3. Bending Force and Length

Bending Force: The press brake has a 100-ton bending force, making it suitable for bending medium to thick sheets of material. The machine delivers consistent force across the full length of the bending surface, ensuring high-quality, accurate bends.

Bending Length: With a bending length of 3200 mm, this machine can handle large sheets, making it ideal for industries that require the bending of long parts such as structural components, chassis, and body panels.

4. Maximum Opening Height and Stroke

Maximum Opening Height: The maximum opening height is 460 mm, allowing the machine to accommodate thicker workpieces, providing greater flexibility for a variety of material thicknesses and sizes.

Ram Stroke: The machine has a 200 mm ram stroke, enabling it to bend a wide range of sheet thicknesses while maintaining consistent bending angles.

5. Fast Downward and Return Speeds

The 100T 3200mm CNC Hydraulic Double Servo Press Brake is designed for high-speed operation, increasing overall productivity:

Fast Downward Speed: The machine has a downward speed of 240 mm/s, enabling fast operation cycles and higher throughput. This helps reduce processing time for each part, enhancing the efficiency of the bending process.

Return Speed: The return speed of the machine is 220 mm/s, allowing the ram to return quickly to the top position, reducing cycle time between bends and maximizing overall productivity.

6. Backgauge System

The machine features an advanced backgauge system that allows for precise material positioning:

Adjustable Backgauge: The CNC-controlled backgauge moves along multiple axes to accurately position the sheet for each bend. The backgauge adjusts automatically based on programmed parameters, ensuring that the material is aligned correctly every time.

Multi-Axis Movement: The backgauge moves in multiple axes, allowing for accurate positioning even when multiple bends or complex part geometries are required.

7. Precision and Repeatability

High Precision: The machine’s hybrid drive system provides high accuracy, with precise control over the ram and backgauge movements. This ensures that each bend is accurate to the specified angle, thickness, and tolerance.

Repeatability: The hybrid technology minimizes variation between bends, ensuring that each part is consistently produced to the same high standard. This is especially important for high-volume production and industries that require tight tolerances.

8. Springback Compensation

Springback Control: The press brake's CNC control system incorporates springback compensation, which automatically adjusts for the material's tendency to return to its original shape after bending. This ensures that the final product matches the required specifications without the need for manual adjustments.

9. Safety Features

The 100T 3200mm CNC Hybrid Press Brake is equipped with several safety features to protect operators and ensure safe operation:

Safety Guards: The machine includes safety shields and guards to prevent accidental contact with moving parts, providing a secure working environment.

Light Curtains: The machine uses safety light curtains that detect the presence of objects or personnel within the machine’s working area. If an obstruction is detected, the machine automatically halts to prevent accidents.

Emergency Stop: The press brake is equipped with an easily accessible emergency stop button that allows operators to immediately halt the machine if needed.

10. Versatility and Applications

The 100T 3200mm CNC Hydraulic Double Servo Press Brake is versatile and can be used for a wide range of applications across various industries:

Automotive Manufacturing: The machine is used to form complex body parts, chassis, and other automotive components, ensuring precision and consistency.

Aerospace: The press brake is used for bending lightweight, high-strength materials like aluminum and titanium for aircraft components.

Heavy Equipment and Machinery: It is ideal for bending large components for heavy machinery and construction equipment.

Metal Fabrication: The machine is well-suited for general metalworking tasks such as producing custom parts, prototypes, and small-to-medium production runs.