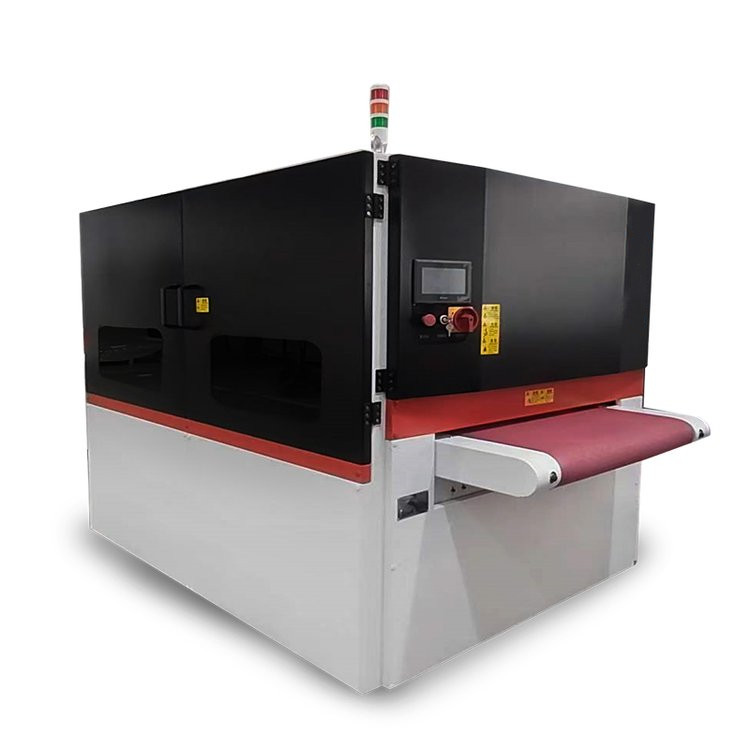

Metal Deburring and Edge Rounding Machine – Technical Specifications & Features

This machine is designed for deburring, edge rounding, and surface finishing of metal parts after flame cutting, laser cutting, punching, and other cutting processes. It ensures the removal of burrs, rounding of sharp edges, and delivers a smooth surface. The equipment is highly suitable for materials such as steel, stainless steel, aluminum, and copper.

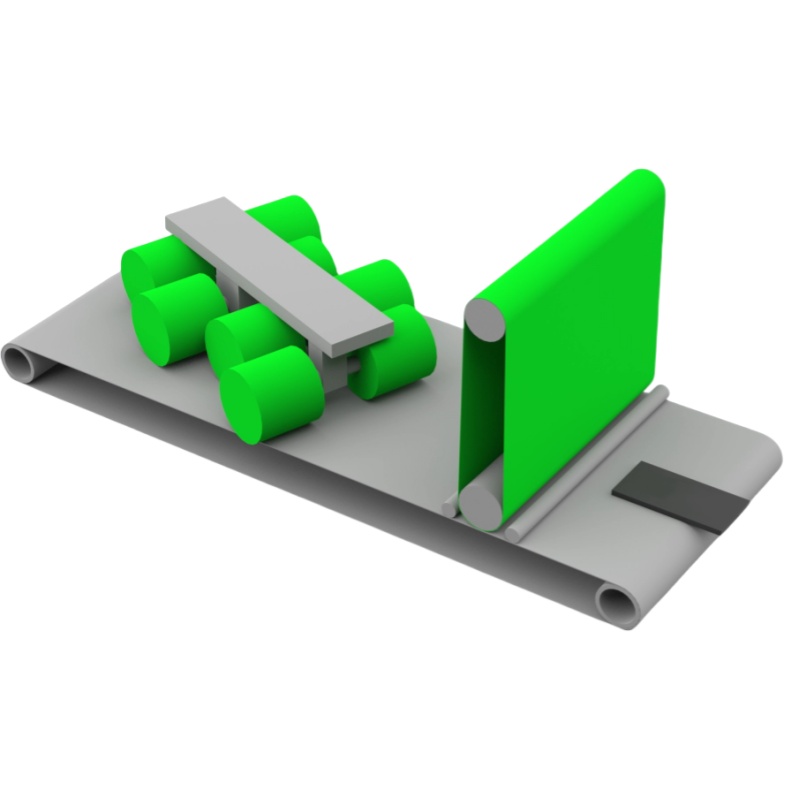

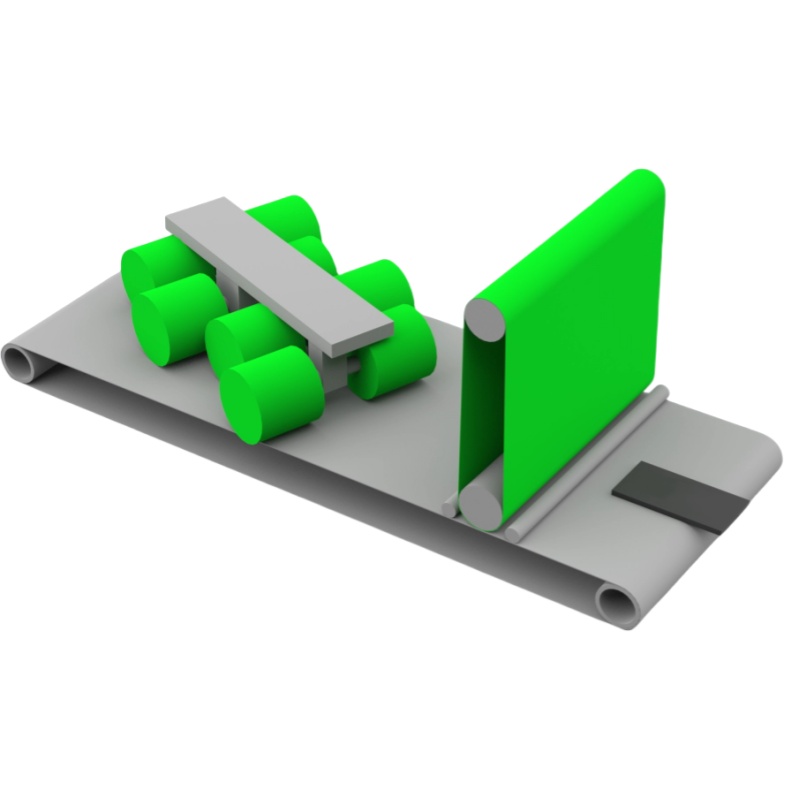

The system consists of a dry-type sanding belt combined with eight universal sanding disc roller brushes. The equipment handles burrs, edges, and holes, removes oxide layers, and polishes metal sheets. The machine is designed for high-volume, continuous production, providing a consistent small-radius edge finish (R-arc effect) on all processed parts.

Key Features & Applications

Deburring and Edge Rounding:

The machine efficiently removes burrs from the edges and holes of metal workpieces. It produces uniformly rounded edges with adjustable radius, ensuring high-quality surface finishes.

It is particularly effective for metal sheets cut by laser, plasma, flame cutting, or stamping processes.

Wide Range of Materials:

This equipment processes a variety of metals, including stainless steel, carbon steel, aluminum, copper, and other non-ferrous metals.

It can handle a wide range of thicknesses from 0.5mm to 80mm, allowing it to process thin sheets and thicker plates alike.

Advanced Multi-Function Processing:

The equipment combines multiple processing functions, including deburring, oxide removal, polishing, and brushing. It uses a sanding belt for larger burrs and eight rotating disc brushes to treat edges and holes, achieving a smooth and consistent finish.

It also offers the option to operate each station independently, allowing for different tasks to be completed separately, optimizing efficiency.

Flexible Processing Design:

The equipment’s multi-functional design allows for versatile processing of parts. For example, the sanding belt can independently perform oxide removal and polishing, while the sanding disc roller brushes handle the deburring and edge rounding.

The system is equipped with a variable-speed conveyor for precise control over material handling, allowing it to process parts with a width up to 1320mm and thicknesses ranging from 0.5mm to 80mm.

High Efficiency and Low Cost:

The continuous feeding and pass-through processing design enhance production efficiency, allowing the machine to handle a large volume of parts.

Compared to manual deburring and edge rounding, this machine significantly reduces processing time and improves consistency, resulting in lower production costs per unit.

Safety and Environmental Protection:

The machine is equipped with a wet-type dust collector that captures grinding dust, providing a safer and cleaner working environment. The high-flow fan ensures effective dust extraction, and the water spray system filters the dust, preventing pollution and allowing metal powder recycling.

The dust collection system reduces safety hazards associated with airborne metal particles, improving operator health and compliance with environmental regulations.

Precision Control:

The machine offers precise adjustment for both processing thickness and brush compensation, with servo motors providing a high degree of accuracy (0.01mm), ensuring consistent surface finishes on all parts.

The adjustable speed for both the sanding belt and disc brushes allows operators to fine-tune the system for different materials and processing requirements.

Technical Specifications

| Feature | Specification |

| Maximum Processing Width | ≤ 1320mm |

| Processing Thickness Range | 0.5mm ~ 80mm |

| Minimum Processing Size | 50mm × 50mm (solid parts) |

| Main Processing Functions | Deburring, Edge Rounding, Oxide Removal, Polishing, Surface Brushing |

| Main Power | 50KW |

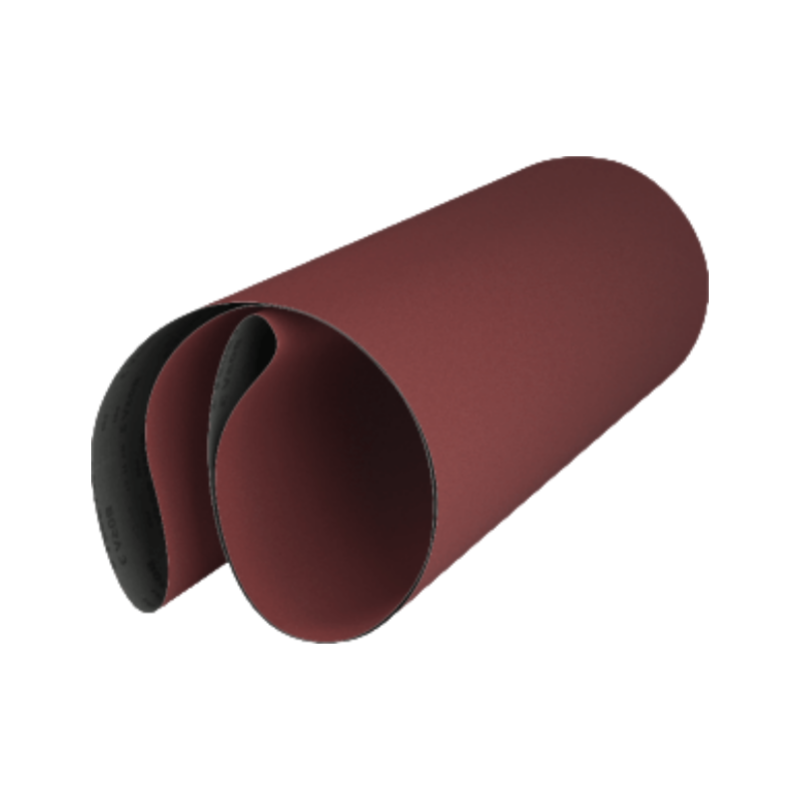

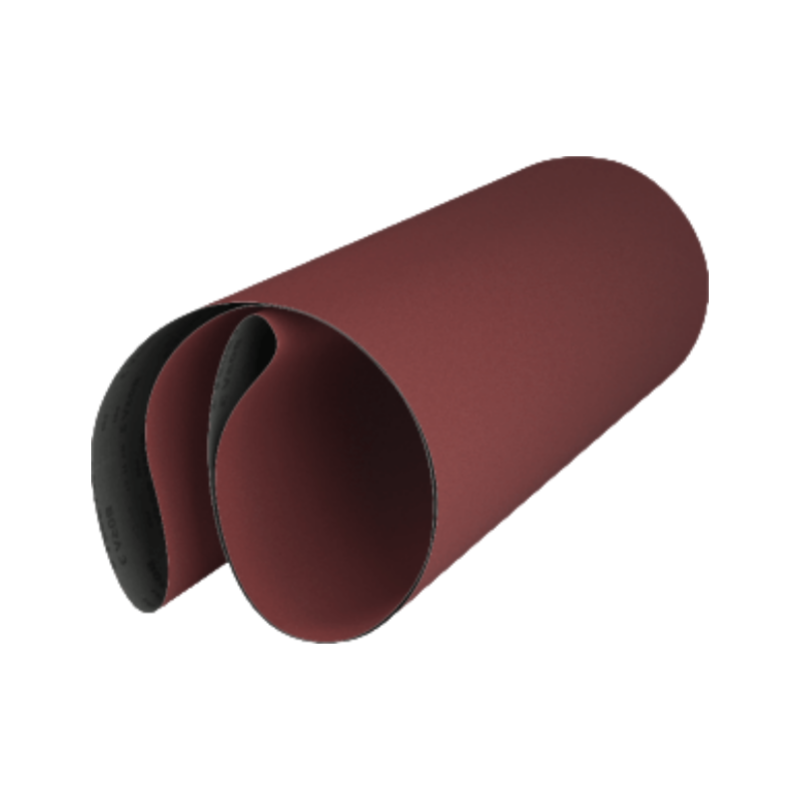

| Sanding Belt Size | Φ1910mm × 1350mm |

| Disc Brush Size | Φ300mm × 400mm |

| Conveyor Speed | 0.5~6 m/min (variable) |

| Sanding Belt Speed | 18 m/s |

| Brush Rotation Speed | 8~26 m/s (adjustable) |

| Brush Revolution Speed | 1~15 rpm (adjustable) |

| Number of Brush Heads | 8 sets |

| Brush Compensation Precision | 0.01mm |

| Dust Extraction Volume | 5000 m³/h |

| Equipment Dimensions | 3800mm × 2300mm × 2400mm |

| Weight | 5 tons |

Advantages of the Equipment

Enhanced Production Efficiency:

Consistent and High-Quality Finishes:

The combination of sanding belts and rotating disc brushes ensures uniform deburring, edge rounding, and polishing. It delivers a consistent finish across all processed parts, superior to manual methods.

Flexible Operation:

The sanding belt and disc brushes can operate independently, allowing for customized treatment of different parts, including surface brushing, oxide removal, and deburring. This feature adds flexibility and efficiency to the processing.

Low Operational Costs:

The automated nature of the machine reduces the need for manual labor and minimizes errors, lowering overall operational costs. Additionally, the precise control over the processing reduces material waste.

Safe and Environmentally Friendly:

Versatility:

The machine can process a wide variety of materials, including stainless steel, carbon steel, aluminum, copper, and non-ferrous metals, making it a versatile solution for many industries.