ZHN-01S Industrial Nitrogen Generator with PLC Control

20 Nm³/min | 95%-99.999% Purity | Designed for Automated Laser Welding Systems

Key Features

✅ Precision PLC Control

7-inch multilingual touchscreen (English/Chinese/European languages)

Real-time monitoring of purity, pressure, and flow rate

Automated pressure stabilization (0.5–0.8 MPa output)

✅ Advanced Filtration System

Triple-stage filtration:

Coarse particulate removal (>1μm)

Precision filtration (0.01μm)

Activated carbon adsorption (oil vapor removal)

✅ Maintenance-Free Operation

Automatic drainage system (condensate removal)

Self-cleaning CMS (Carbon Molecular Sieve) beds

Low energy consumption (56W)

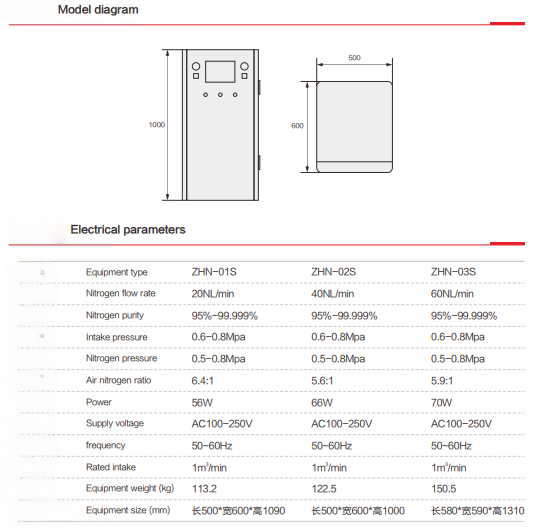

✅ Compact Industrial Design

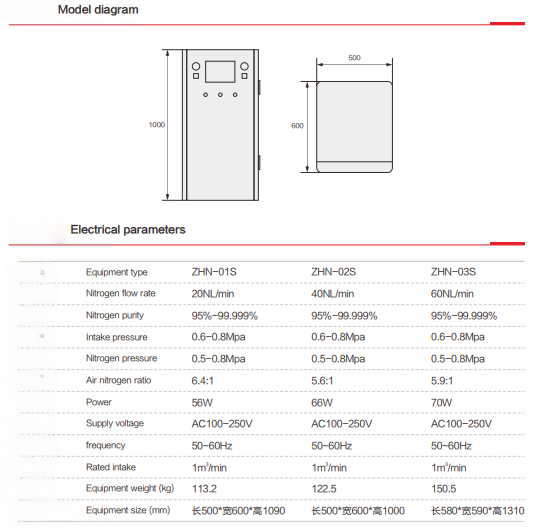

Technical Specifications

| Parameter | Specification |

| Model | ZHN-01S |

| Flow Rate | 20 Nm³/min (continuous) |

| Purity Range | 95%–99.999% (adjustable via HMI) |

| Operating Pressure | 0.6–0.8 MPa (intake) |

| Output Pressure | 0.5–0.8 MPa (stable for welding) |

| Air/Nitrogen Ratio | 6.4:1 (high efficiency) |

| Power Supply | AC 100–250V, 50/60Hz |

| Air Consumption | 1 m³/min |

Applications

Competitive Advantages

vs. Gas Cylinders:

vs. Membrane Generators:

vs. Standard PSA Systems:

Target Keywords for SEO

*"20 Nm³/min PLC nitrogen generator for laser welding"*

"Automated nitrogen gas system with touchscreen"

"99.999% purity nitrogen generator for robotics"

"Low-maintenance PSA nitrogen generator"

"Industrial nitrogen supply for fiber lasers"

Ordering Information

Model: ZHN-01S

Flow Rate: 20 Nm³/min

Purity: 95%-99.999%