High Purity Nitrogen (99.99%)

The ZHN-02-PLC nitrogen generator produces nitrogen with a purity of 99.99%, which is ideal for laser cutting, especially for fiber lasers and CO2 lasers. High-purity nitrogen prevents oxidation during the cutting process, ensuring clean and precise cuts.

Stable Nitrogen Flow (2NM³/h)

Capable of delivering 2NM³/h of nitrogen, the ZHN-02-PLC provides a stable and consistent nitrogen supply, meeting the demands of modern industrial laser cutting machines.

Controllable Output

The nitrogen flow is controllable, allowing users to adjust the output flow rate based on their specific needs, optimizing both nitrogen use and operational efficiency.

Low Energy Consumption (15W)

With a power consumption of just 15W, this generator operates efficiently, reducing operational costs while maintaining consistent nitrogen output.

Compact Design

The generator features a compact design with dimensions of 500 x 450 x 780 mm, making it easy to integrate into existing setups without occupying excessive space.

Wide Application Range

Ideal for laser cutting applications, the generator is suited for cutting metals, plastics, and other materials that require a controlled and inert environment during processing.

Reliable Pressure Control

The inlet pressure ranges between 0.6 to 0.8 MPa, while the output nitrogen pressure is maintained at or below 0.6 MPa, ensuring safe and stable operation.

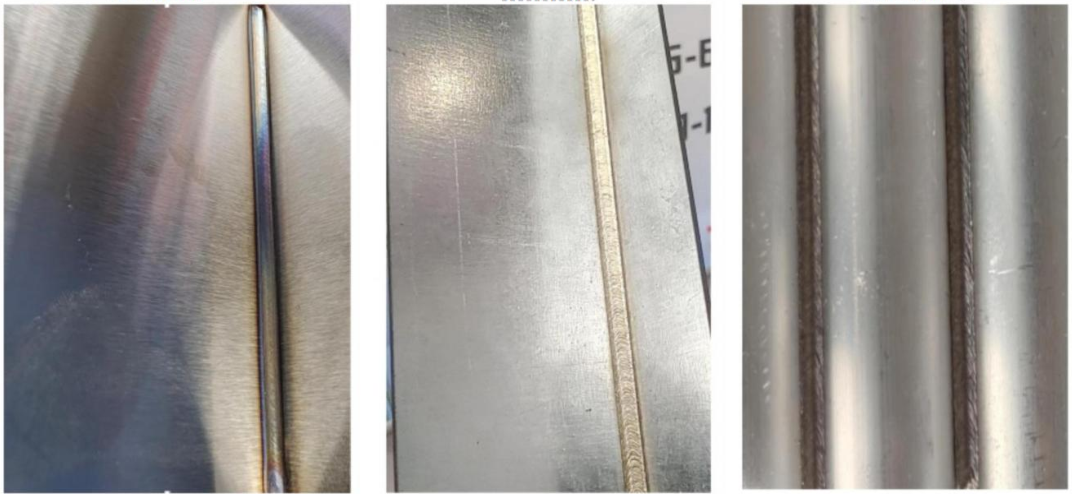

Laser Cutting:

Nitrogen is commonly used in laser cutting to prevent oxidation, provide clean cuts, and reduce the risk of material contamination, especially with stainless steel, aluminum, and other metals.

Fiber Lasers:

Fiber lasers require nitrogen for efficient cutting, especially in applications involving high-precision cuts with minimal material burn.

CO2 Lasers:

Nitrogen is used in CO2 laser cutting to shield the cutting area from contaminants and provide a smooth, clean cutting edge on materials like metals, plastics, and organic materials.

Aerospace and Automotive Industries:

Industries that rely on high-precision laser cutting to manufacture components such as aircraft parts and automotive parts can benefit from the clean, efficient operation provided by the nitrogen generator.

Metalworking and Manufacturing:

Nitrogen generators are used in metalworking and manufacturing to ensure the quality and precision of laser-cut products, especially in high-volume production environments.