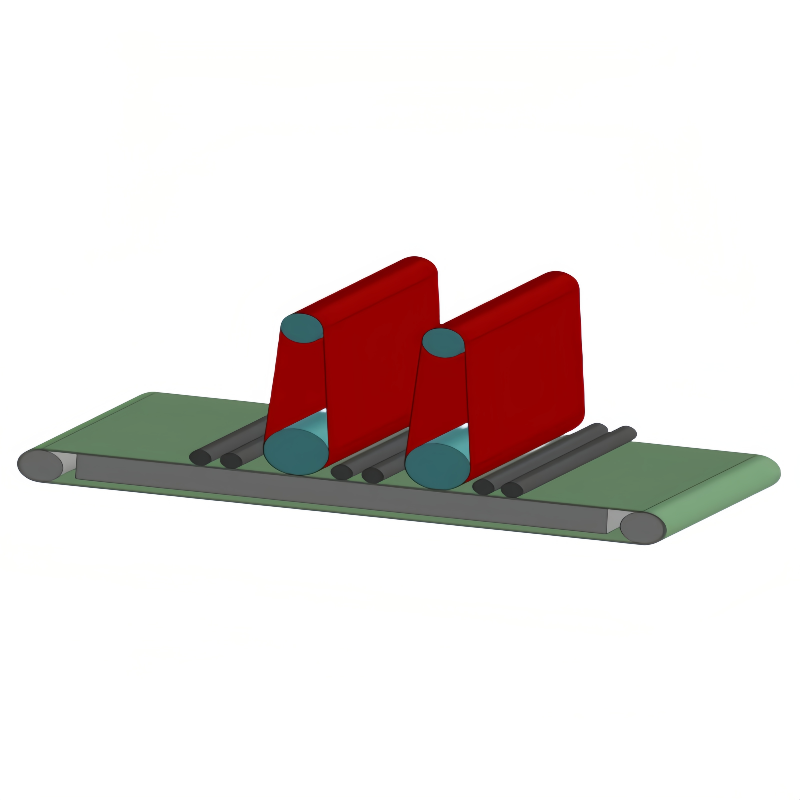

Conveyor Wide Belt Sander for Metal – 400mm

The Conveyor Wide Belt Sander for Metal (400mm) is a high-performance, industrial-grade sanding machine designed specifically for surface finishing, deburring, edge radiusing, and dimensioning of metal parts. This machine is equipped with an advanced conveyor system, which ensures precise and efficient handling of metal workpieces, making it ideal for large-scale production environments.

Perfect for use with materials such as steel, aluminum, copper, and other metals, this 400mm wide belt sander is designed to improve the efficiency and consistency of metal surface treatments. Whether it's deburring edges, polishing surfaces, or achieving a uniform thickness, this machine is built for precision and durability.

Wet Belt Sander:

| Specification | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm |

| Max Working Height | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| Min Working Length | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| First Abrasive Belt Power | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW |

| Second Abrasive Belt Power | - | 5.5 kW | - | 5.5 kW | 5.5 kW | 5.5 kW |

| Third Abrasive Belt Power | - | - | - | 5.5 kW | - | 5.5 kW |

| Polishing Wheel Power | - | - | - | - | 5.5 kW | 5.5 kW |

| Rotating Motor Power | - | - | - | - | - | - |

| Feed Motor Power | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Lift Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW |

| Swing Motor Power | - | - | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Vacuum Motor Power | - | - | - | - | - | - |

| Machine Dimensions (L×W×H) | 1.8×1.5×1.8 m | 2.1×1.5×1.8 m | 2.1×1.5×1.8 m | 2.4×1.5×1.8 m | 2.4×1.5×1.8 m | 2.7×1.5×1.8 m |

| Machine Weight | 1000 kg | 1200 kg | 1200 kg | 1500 kg | 1500 kg | 1800 kg |

| Abrasive Belt Size | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm |

Key Features:

Efficient Conveyor System: The conveyor belt is engineered to handle large quantities of metal parts with ease, enabling fast, continuous processing and ensuring that parts are delivered to the sanding head with precision. This system improves throughput while maintaining high accuracy and consistency.

Versatile Metal Surface Treatment: Capable of handling a wide range of metal surface finishing processes, including deburring, edge rounding, polishing, and dimensioning. It is ideal for processing materials such as steel, aluminum, copper, and more.

High-Performance Sanding: The 400mm wide sanding belt is equipped with multiple motorized sanding units, offering flexible sanding power and efficiency for various tasks. Operators can achieve consistent surface finishes, remove rust, scale, and burrs from the workpieces, and prepare them for further processing or finishing.

Adjustable Settings: The sanding pressure, speed, and conveyor feed rate are fully adjustable, allowing for customization based on the specific requirements of each project. This flexibility ensures the machine can handle different metal thicknesses and achieve the desired surface finish.

Compact and Robust Design: Designed to handle high-duty cycles, this wide belt sander features a compact yet sturdy construction, ensuring durability and long-lasting performance even in demanding production environments. The solid frame minimizes vibrations and enhances the precision of metal surface treatments.

Improved Dust Management: The machine is equipped with a high-efficiency dust collection system, which ensures that airborne contaminants are effectively removed, providing a cleaner work environment and reducing the risk of health hazards from metal dust.

User-Friendly Operation: With an intuitive control panel, easy-to-use settings, and a well-designed feed mechanism, operators can quickly get up to speed and efficiently manage the sanding process. This makes the machine highly productive and minimizes the need for extensive operator training.

Applications:

Deburring and Edge Rounding: Removes sharp edges, burrs, and imperfections left by cutting, laser cutting, or stamping processes.

Surface Polishing and Finishing: Achieves high-quality finishes on metal surfaces, improving aesthetics and resistance to corrosion.

Metal Dimensioning: Consistently calibrates the thickness and flatness of metal parts, ensuring uniformity in size.

Rust and Oxide Removal: Removes rust, oxidation, and scale from metal surfaces for improved appearance and subsequent treatments.