Butfering Steel Master 400mm Wet Belt Sander / Buffer with Magnetic Conveyor Table

The Butfering Steel Master Series Wet Belt Sanders and Buffers are advanced industrial machines designed for high-precision metal surface treatment. These machines are perfect for various applications such as deburring, polishing, grinding, dross removal, edge radiusing, and more. Featuring a wide range of models, including the R5240, RR5240, RP5240, RRR5340, RRP5340, and RRRP5440, these machines come with several customizable features to meet the specific needs of different industries.

400mm "WET" Wide Belt Sander for Metal Finishing and Grinding with Magnetic Conveyor Worktable - Model RRR5340

The 400mm Wet Wide Belt Sander – Model RRR5340 is a state-of-the-art industrial machine designed for metal finishing, grinding, and deburring applications. It is equipped with a magnetic conveyor worktable, making it ideal for precision processing of metal workpieces, including steel, aluminum, and non-ferrous metals. This powerful, versatile sander offers excellent performance in a variety of applications where fine surface finishing, edge radiusing, and dross removal are required.

Wide Belt Sander Design: The 400mm wide sanding belt ensures that even larger workpieces can be processed efficiently. The machine can handle a wide range of metal finishing tasks, from coarse grinding to fine polishing, giving operators a high level of flexibility in their production environment.

Wet Sanding for Better Results: The wet sanding process helps to significantly reduce dust and improve the surface finish by preventing heat buildup during the grinding process. This results in a smoother, more polished finish, and prevents material overheating, which can degrade surface quality.

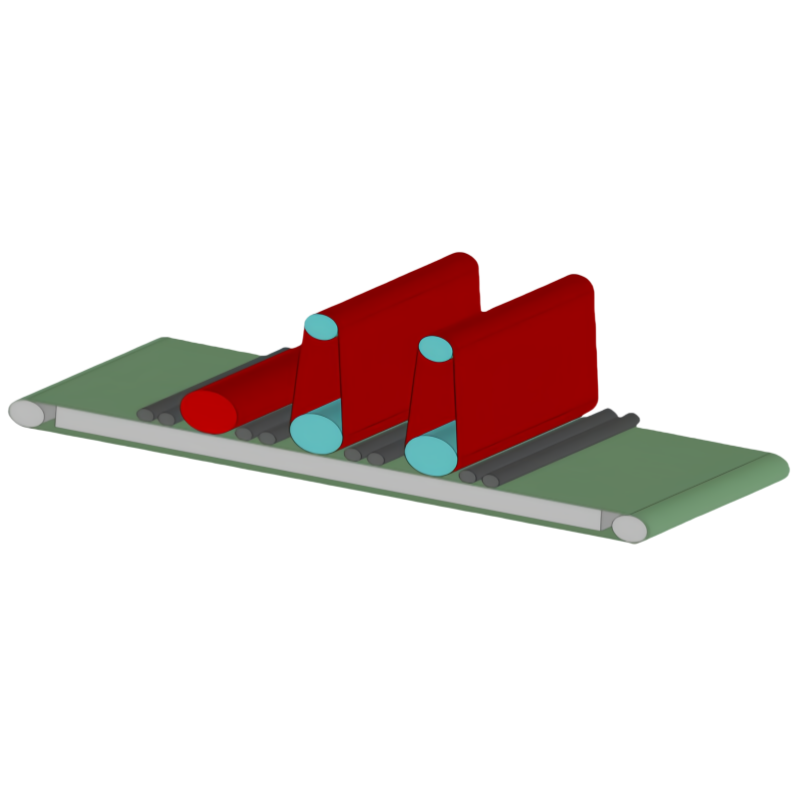

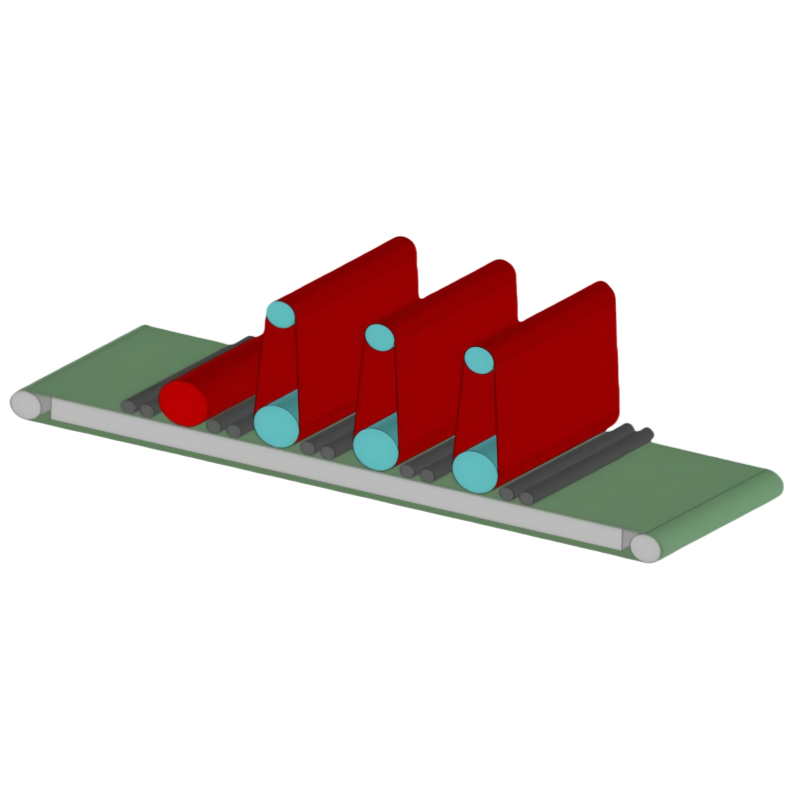

Magnetic Conveyor Worktable: The machine features a magnetic conveyor worktable, which securely holds metal parts during the sanding process. This magnetic system ensures precise alignment and eliminates any potential for parts to shift during operation, making it ideal for precision metal finishing and grinding.

Powerful Motorization: The machine comes with multiple sanding belt motors (including up to 7.5kW power for the first belt), providing ample power for various grinding applications. This allows the machine to handle tough jobs like deburring, edge rounding, and oxide skin removal with ease.

Precision Sanding and Grinding: The RRR5340 is designed for high-precision applications. The wet belt sanding system allows for consistent thickness calibration, which is crucial for achieving the desired finish on metal surfaces. It also features precise adjustment mechanisms for setting the sanding pressure and speed.

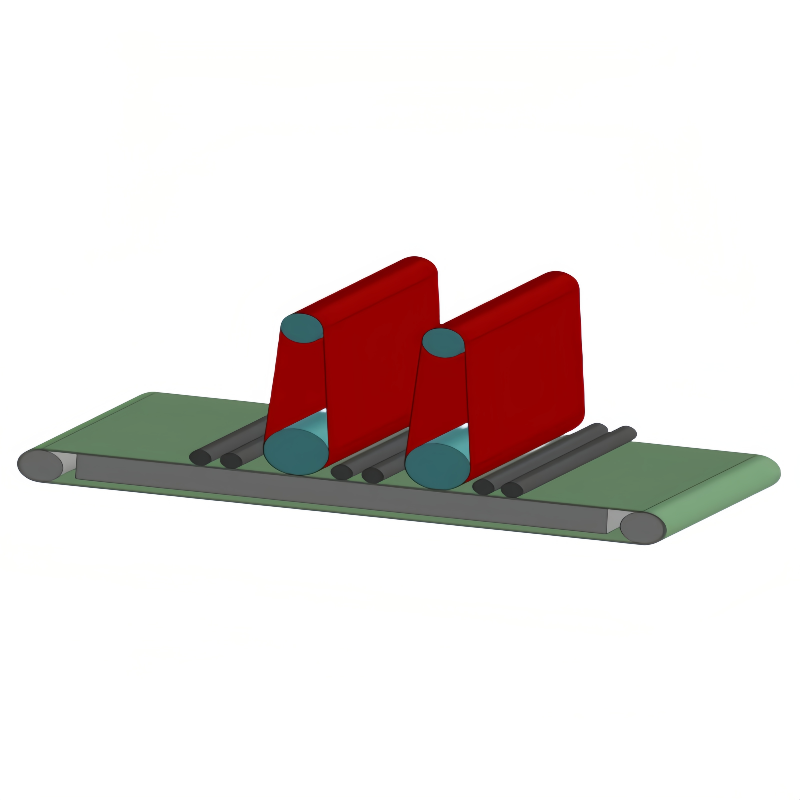

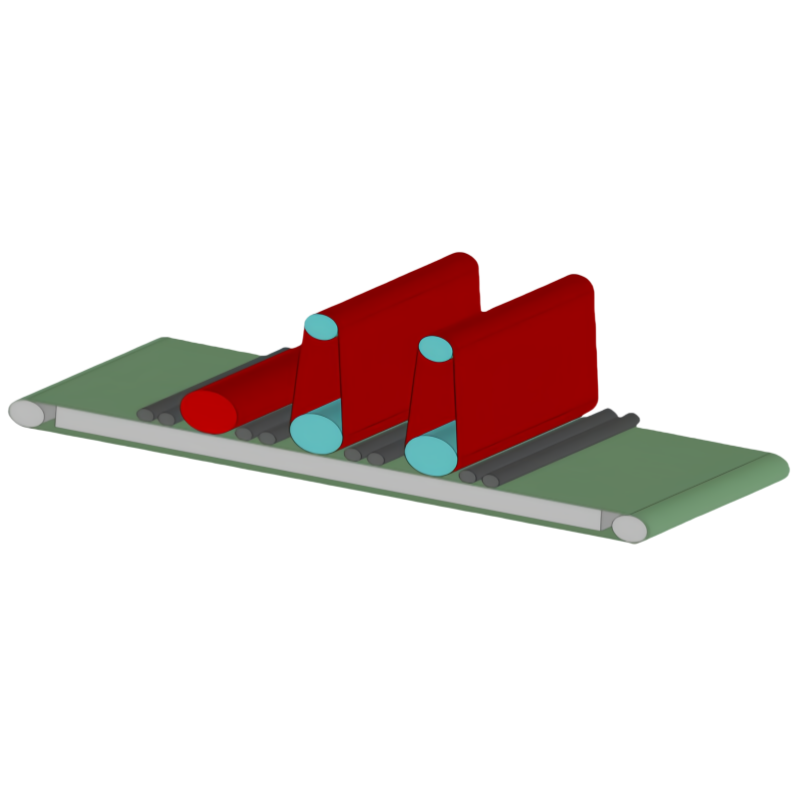

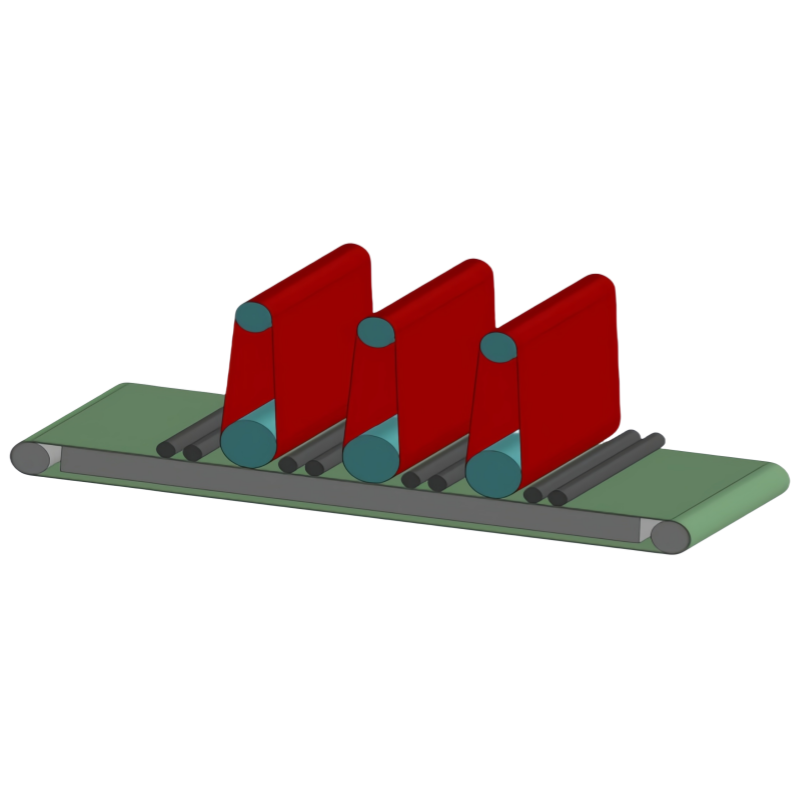

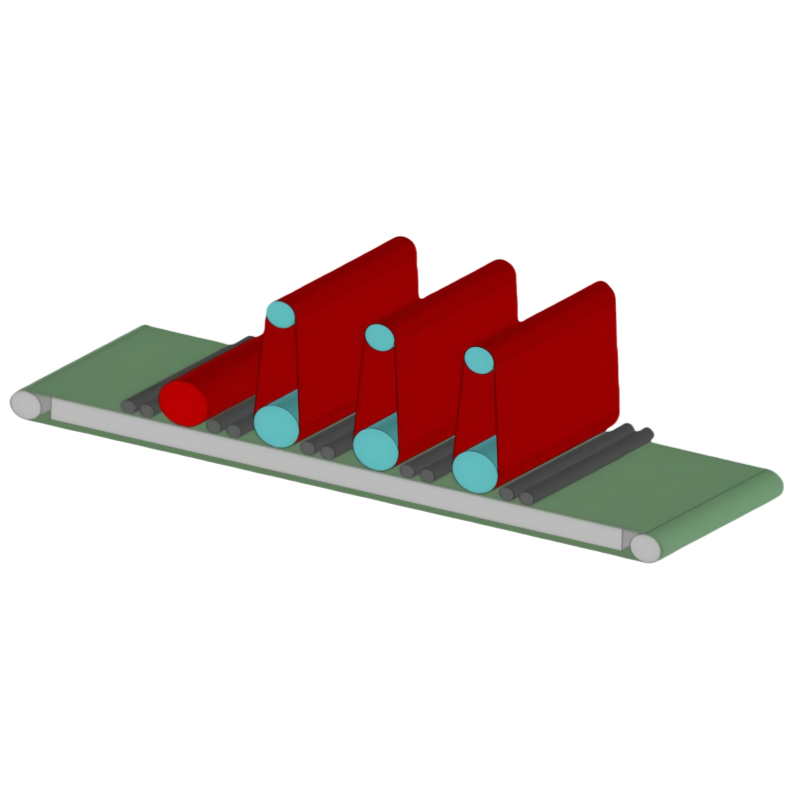

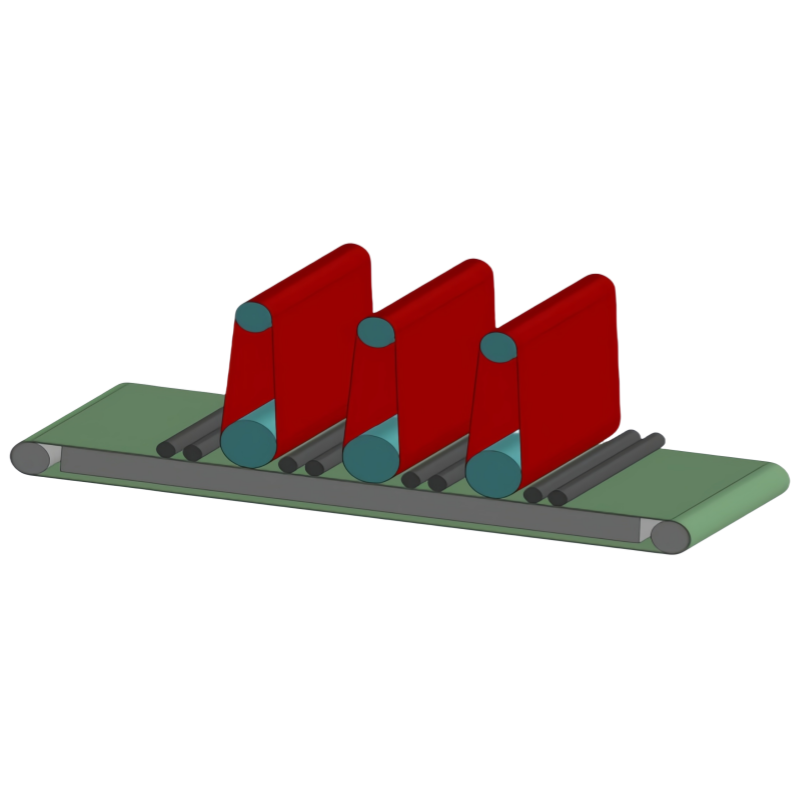

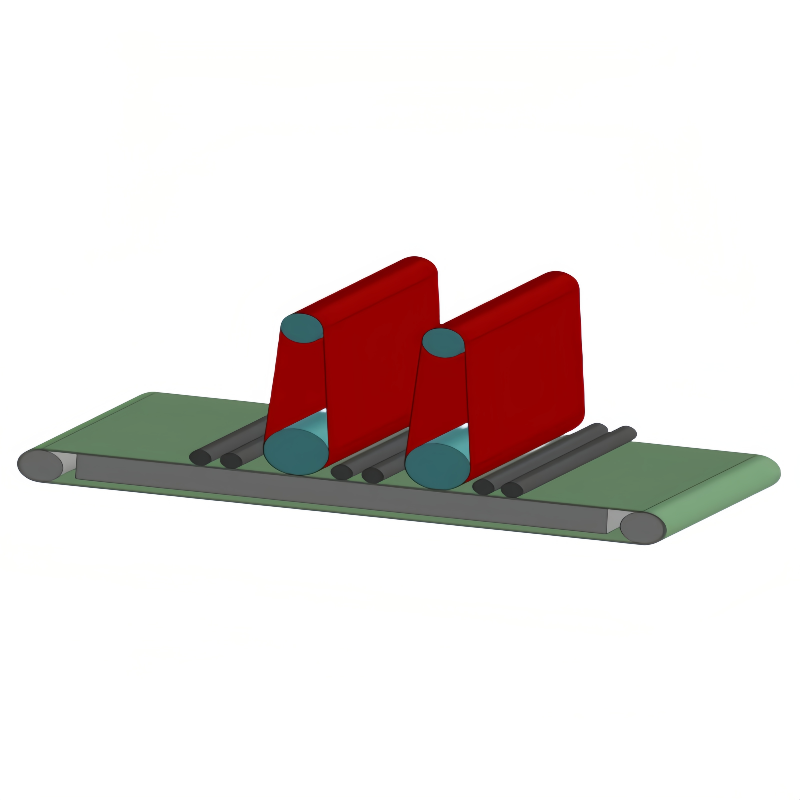

Multiple Belt Stations: The machine can be equipped with multiple sanding belts to handle different stages of the finishing process. For instance, a coarse belt might be used for deburring and a finer belt for polishing, allowing for a fully integrated metal finishing solution.

User-Friendly Control System: The RRR5340 comes with an intuitive PLC control system, which allows operators to easily adjust settings like feed rates, sanding pressure, and belt speed. This ensures that every sanding and grinding task can be customized to meet specific processing requirements.

1. Models Overview:

| Specification | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm |

| Max Working Height | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| Min Working Length | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| First Abrasive Belt Power | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW |

| Second Abrasive Belt Power | - | 5.5 kW | - | 5.5 kW | 5.5 kW | 5.5 kW |

| Third Abrasive Belt Power | - | - | - | 5.5 kW | - | 5.5 kW |

| Polishing Wheel Power | - | - | - | - | 5.5 kW | 5.5 kW |

| Rotating Motor Power | - | - | - | - | - | - |

| Feed Motor Power | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Lift Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW |

| Swing Motor Power | - | - | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Vacuum Motor Power | - | - | - | - | - | - |

| Machine Dimensions (L×W×H) | 1.8×1.5×1.8 m | 2.1×1.5×1.8 m | 2.1×1.5×1.8 m | 2.4×1.5×1.8 m | 2.4×1.5×1.8 m | 2.7×1.5×1.8 m |

| Machine Weight | 1000 kg | 1200 kg | 1200 kg | 1500 kg | 1500 kg | 1800 kg |

| Abrasive Belt Size | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm |

Applications:

Metal Surface Finishing: The wet wide belt sander is used to achieve high-quality finishes on metal surfaces, whether you are working with carbon steel, stainless steel, aluminum, or copper. It ensures that surfaces are smooth, free from defects, and ready for further processing or coating.

Deburring: The machine is ideal for deburring metal parts after processes like laser cutting, punching, shearing, or flame cutting. The wet sanding process removes burrs and sharp edges, resulting in parts that are safer and ready for assembly.

Edge Radiusing: The magnetic conveyor worktable ensures that workpieces are held securely, allowing for precise edge radiusing. This is ideal for applications where metal parts need rounded edges for aesthetic, safety, or functional purposes.

Dross Removal: After laser cutting or plasma cutting, metal parts often have dross that needs to be removed. The wet belt sander excels at eliminating dross and ensuring that the metal edges are smooth and clean.

Polishing and Finishing: The polishing wheel and wet sanding belts are ideal for producing a high-quality polished finish on metal parts, creating a sleek, professional appearance. The combination of wet sanding and polishing ensures an even finish across the entire workpiece.

Advantages:

Enhanced Surface Quality: The wet sanding process keeps temperatures low, preventing warping and improving surface consistency. The magnetic worktable keeps parts in place for consistent processing.

Versatility: The RRR5340 is suitable for various types of metal and can handle multiple finishing tasks, including grinding, deburring, polishing, and edge rounding.

High Productivity: With the powerful motors and efficient wet sanding process, this machine is capable of processing high volumes of parts while maintaining superior quality and precision.

Energy Efficiency: The RRR5340 is designed to minimize energy consumption, with a variable feed speed and adjustable sanding pressure, making it a cost-effective solution for industrial operations.