Butfering Steel Master 400mm Wet Belt Sander / Buffer with Magnetic Conveyor Table

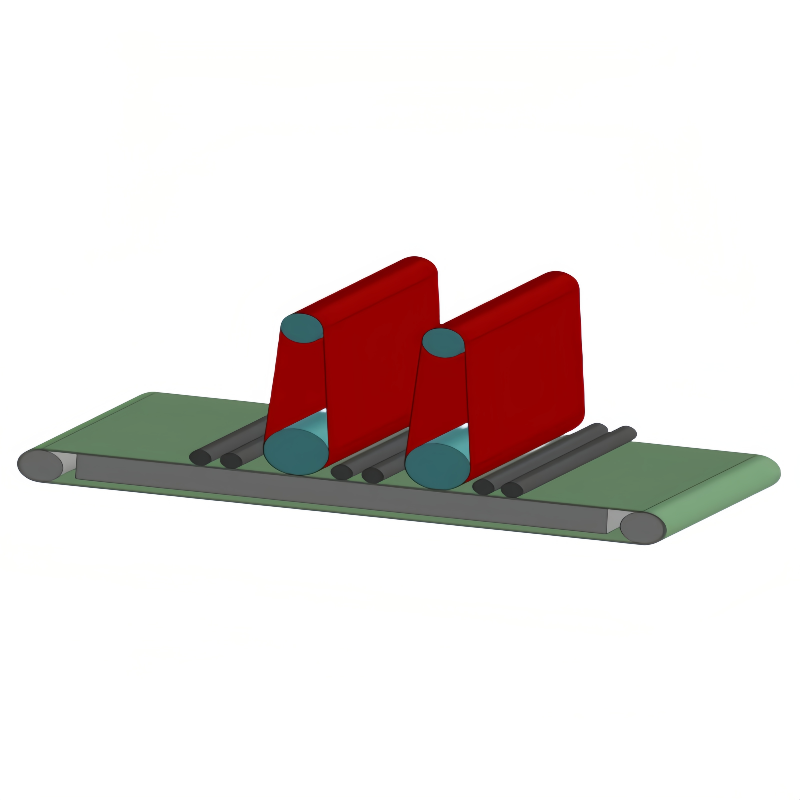

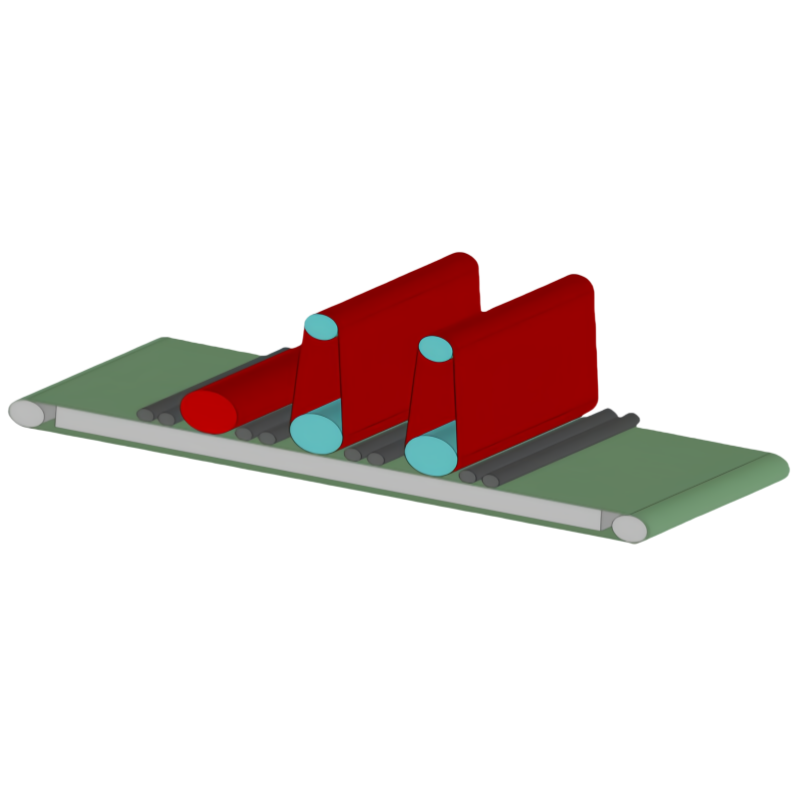

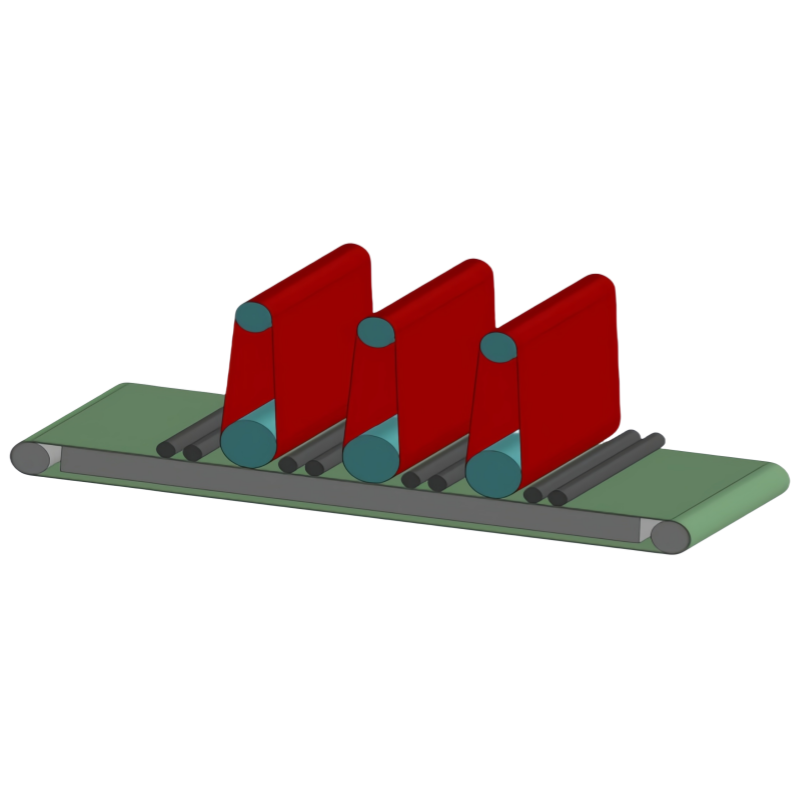

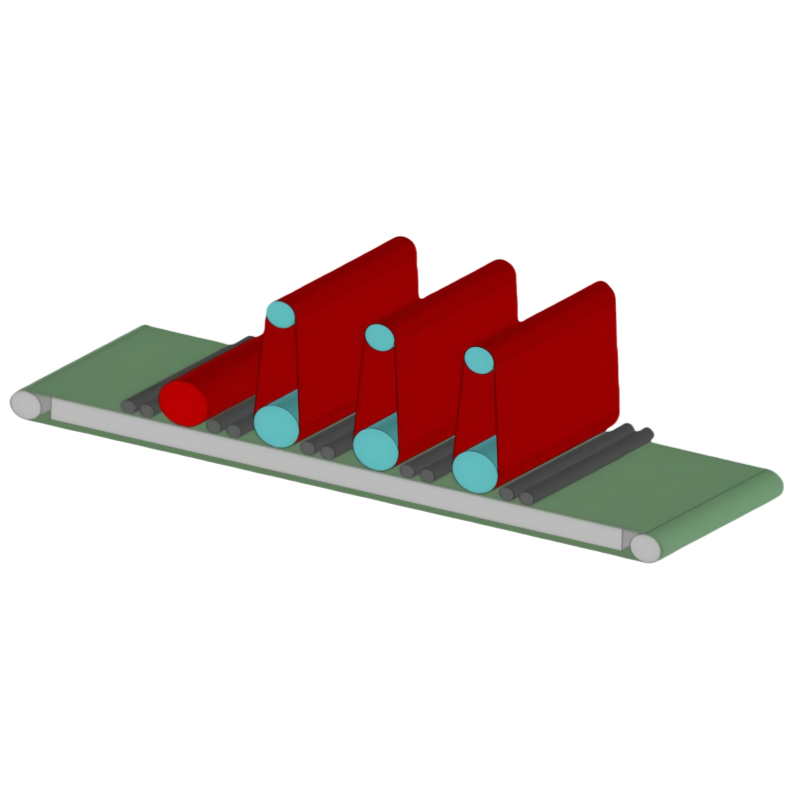

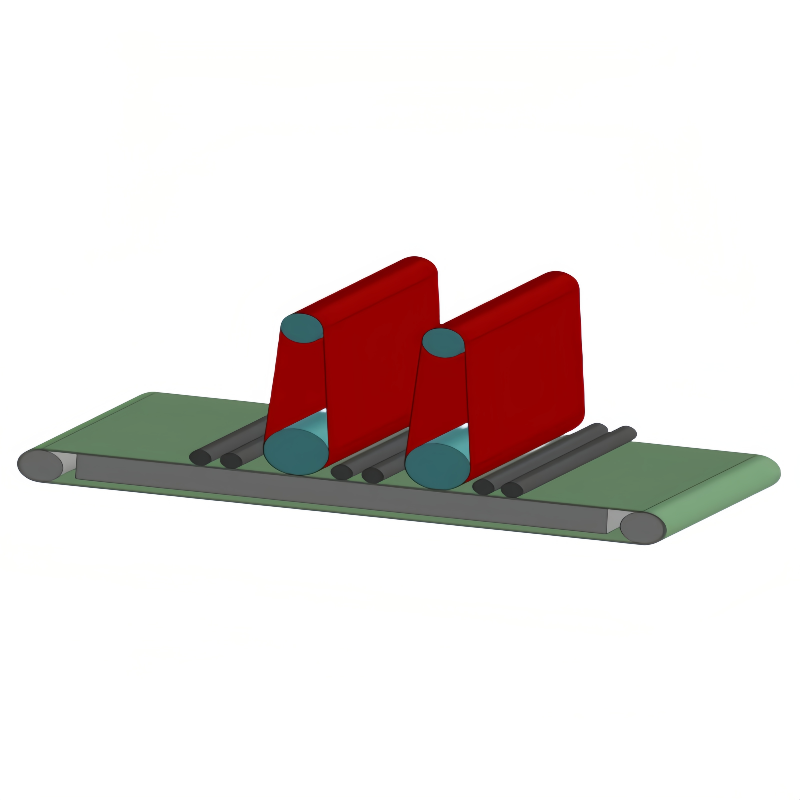

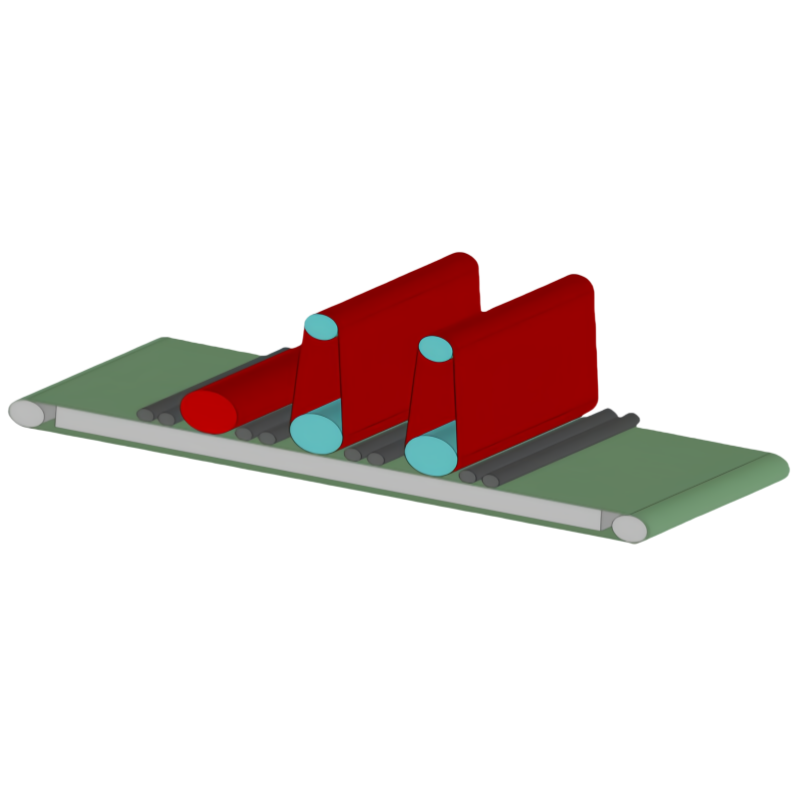

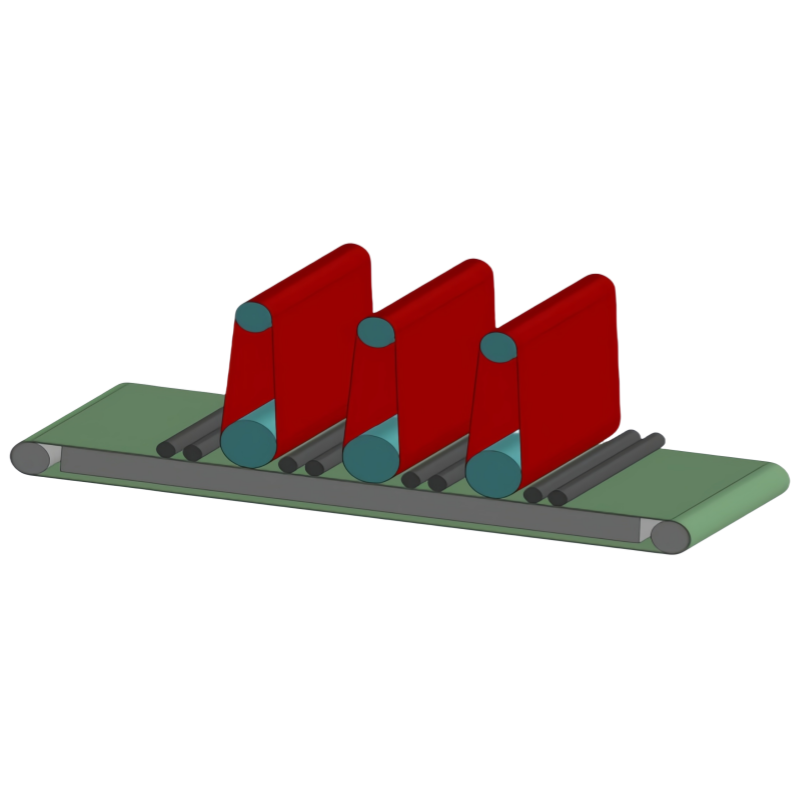

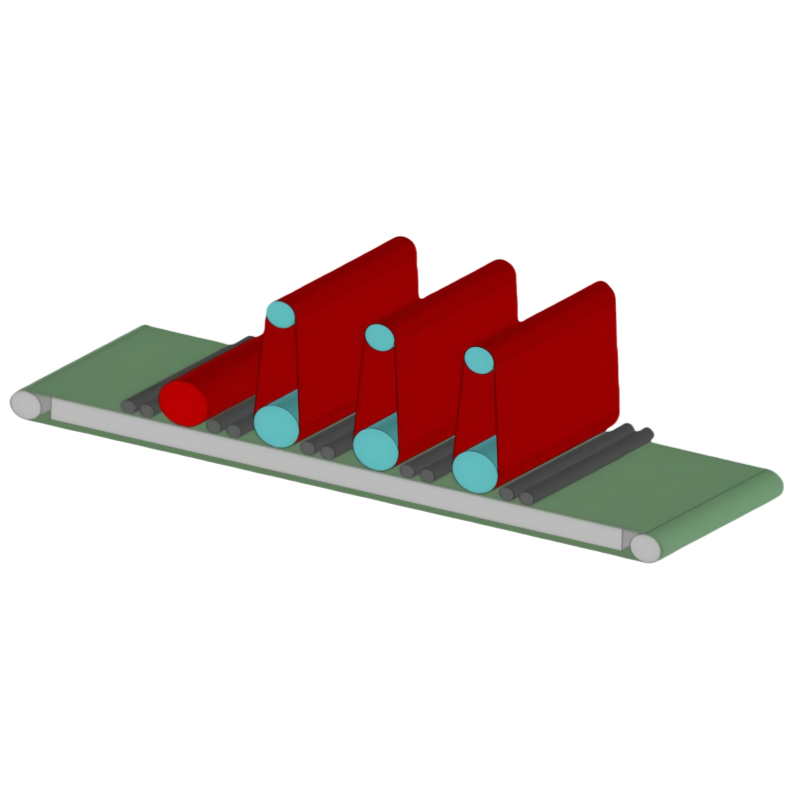

The Butfering Steel Master Series Wet Belt Sanders and Buffers are advanced industrial machines designed for high-precision metal surface treatment. These machines are perfect for various applications such as deburring, polishing, grinding, dross removal, edge radiusing, and more. Featuring a wide range of models, including the R5240, RR5240, RP5240, RRR5340, RRP5340, and RRRP5440, these machines come with several customizable features to meet the specific needs of different industries.

Butfering Steel Master Wet Belt Sander series.

1. Models Overview:

| Specification | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm |

| Max Working Height | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| Min Working Length | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| First Abrasive Belt Power | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW |

| Second Abrasive Belt Power | - | 5.5 kW | - | 5.5 kW | 5.5 kW | 5.5 kW |

| Third Abrasive Belt Power | - | - | - | 5.5 kW | - | 5.5 kW |

| Polishing Wheel Power | - | - | - | - | 5.5 kW | 5.5 kW |

| Rotating Motor Power | - | - | - | - | - | - |

| Feed Motor Power | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Lift Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW |

| Swing Motor Power | - | - | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Vacuum Motor Power | - | - | - | - | - | - |

| Machine Dimensions (L×W×H) | 1.8×1.5×1.8 m | 2.1×1.5×1.8 m | 2.1×1.5×1.8 m | 2.4×1.5×1.8 m | 2.4×1.5×1.8 m | 2.7×1.5×1.8 m |

| Machine Weight | 1000 kg | 1200 kg | 1200 kg | 1500 kg | 1500 kg | 1800 kg |

| Abrasive Belt Size | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm |

2. Key Features and Benefits:

High-Precision Metal Surface Treatment: The Butfering Steel Master Wet Belt Sander / Buffer series is engineered to deliver superior results for various metal surface treatment applications, including deburring, polishing, and edge radiusing. These machines are designed to ensure smooth and even finishes on a variety of metals, such as carbon steel, stainless steel, and aluminum.

Wet Belt Technology: Wet belt sanding significantly reduces the generation of heat during the sanding process, which in turn minimizes the risk of material distortion and overheating. Additionally, the use of water or coolant helps to reduce dust and debris, creating a cleaner, safer work environment.

Versatile Abrasive Belt Options: Different models offer multiple abrasive belts with varying powers, which can be used for different levels of sanding and polishing. Some models (e.g., RRR5340 and RRP5340) feature up to three abrasive belts, offering excellent versatility for processing complex parts.

Powerful Motorization: The machines are equipped with powerful motors to drive the abrasive belts, with the first belt on all models having 7.5 kW of power. The RRR5340 and RRRP5440 feature additional polishing wheel motors to further enhance the surface finishing process.

Magnetic Conveyor Table: The magnetic conveyor table ensures secure holding and consistent movement of metal parts during the sanding process. This feature is particularly useful for handling thin, lightweight, or irregularly shaped materials. The magnetic table provides precise control of part movement, preventing slippage or misalignment during the sanding process.

Automatic Feed and Adjustable Settings: With an automatic feeding system, the machines can continuously process large volumes of material with consistent quality. The adjustable settings for belt speed and pressure ensure that operators can fine-tune the machine to achieve the desired level of finish for different materials.

Compact and Sturdy Design: The Butfering Steel Master Wet Belt Sanders are designed to be space-efficient while maintaining a robust, industrial-grade build. Their compact size and modular design allow them to be integrated into various production lines without occupying excessive floor space.

Ease of Operation and Maintenance: These machines are designed for user-friendly operation, with intuitive controls and easy-to-access components for maintenance. The built-in vacuum systems (in some models) and precision-adjustable sanding settings make the machine efficient and straightforward to use for both novice and experienced operators.

3. Applications:

The Butfering Steel Master Wet Belt Sanders are ideal for use in the following industries:

Metalworking: These machines are well-suited for high-precision metal surface treatments. They can be used for deburring, dross removal, and fine finishing of materials such as carbon steel, stainless steel, and aluminum alloys.

Automotive Manufacturing: Widely used in automotive production for finishing and polishing body panels, engine components, exhaust systems, and other metal parts.

Construction and Heavy Equipment: The Butfering Steel Master Series is also used in the construction and heavy equipment industries, where large metal parts require fine-tuning and smoothing. These machines can handle parts used in structural steel, machinery, and heavy-duty equipment.

Aerospace and Aviation: The precision and reliability of the Steel Master series make it an excellent choice for aerospace and aviation applications, where high-quality metal finishes are critical for safety and performance.

4. Why Choose the Butfering Steel Master Series?

Superior Finish Quality: The combination of wet belt sanding and powerful motorization ensures that the end result is a smooth, consistent, and polished finish on a variety of metals.

Customization and Versatility: With different configurations available (such as the number of abrasive belts and power options), these machines can be customized to meet specific production requirements, offering flexibility for various industries.

High-Performance Standards: Built for industrial environments, these machines are designed to perform consistently over long periods, offering a high level of durability and reliability.

Environmental Considerations: The wet sanding process helps to minimize dust and noise, making these machines more environmentally friendly and suitable for safer working conditions compared to traditional dry sanding machines.