Butfering Steel Master 400mm Wet Belt Sander / Buffer with Magnetic Conveyor Table

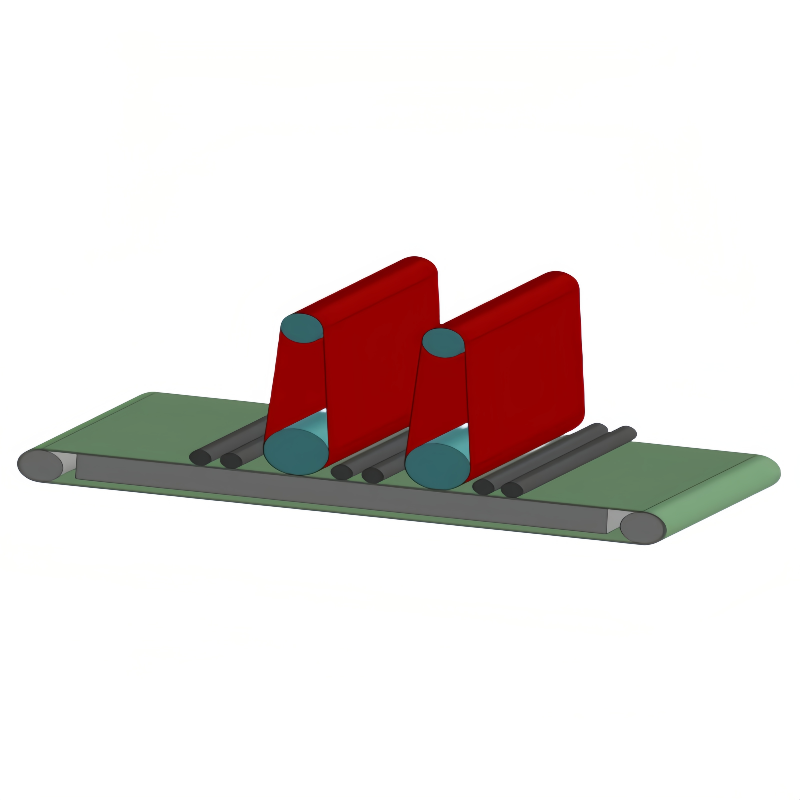

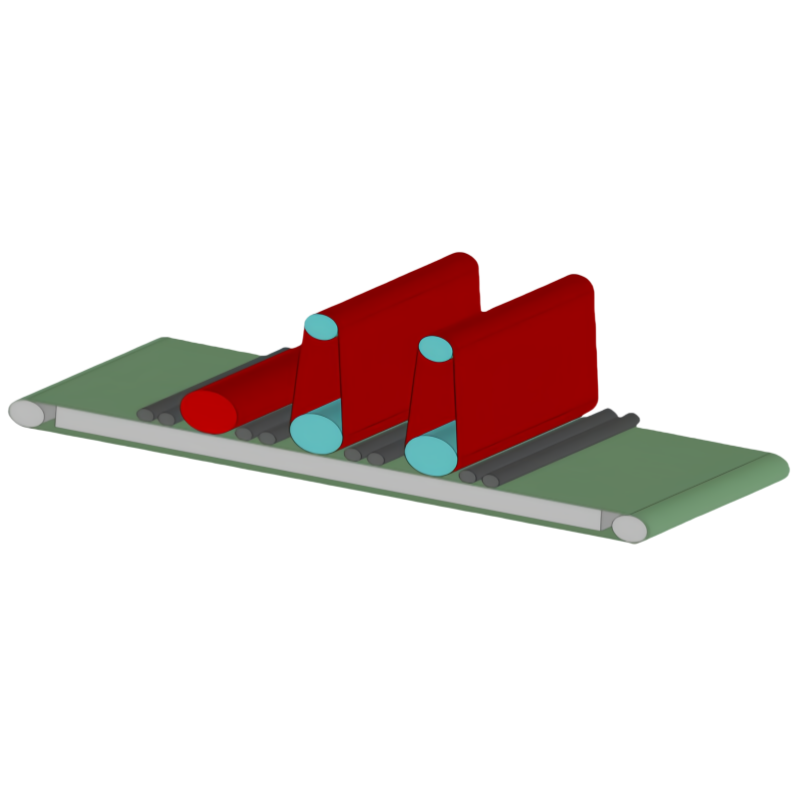

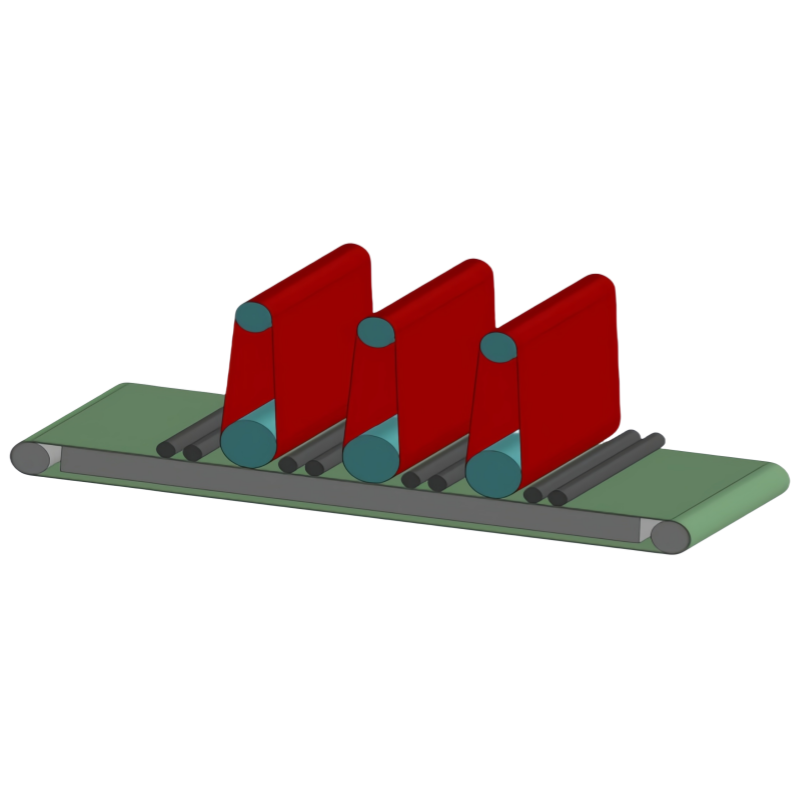

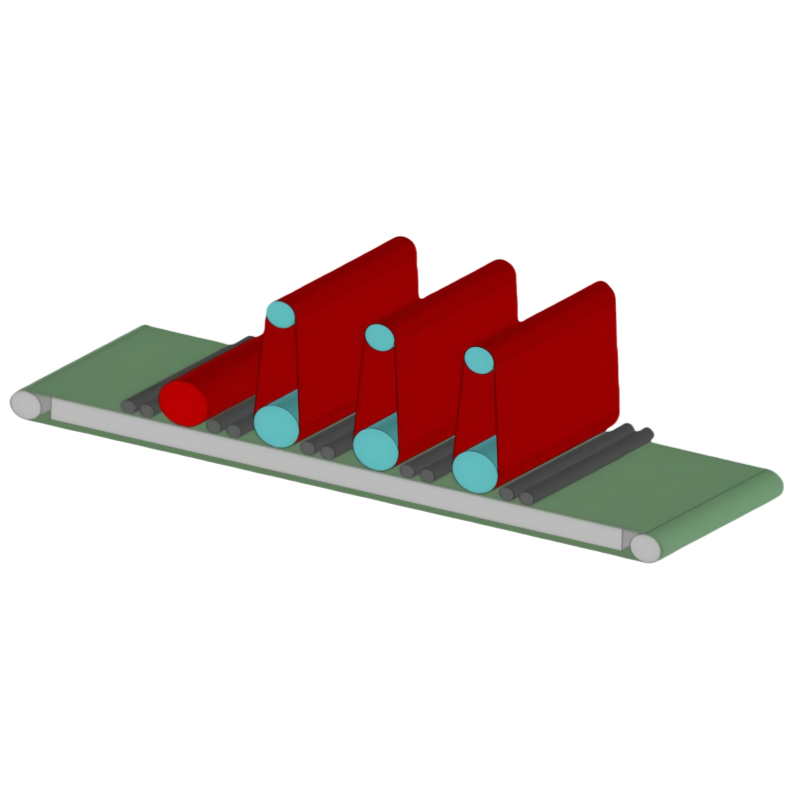

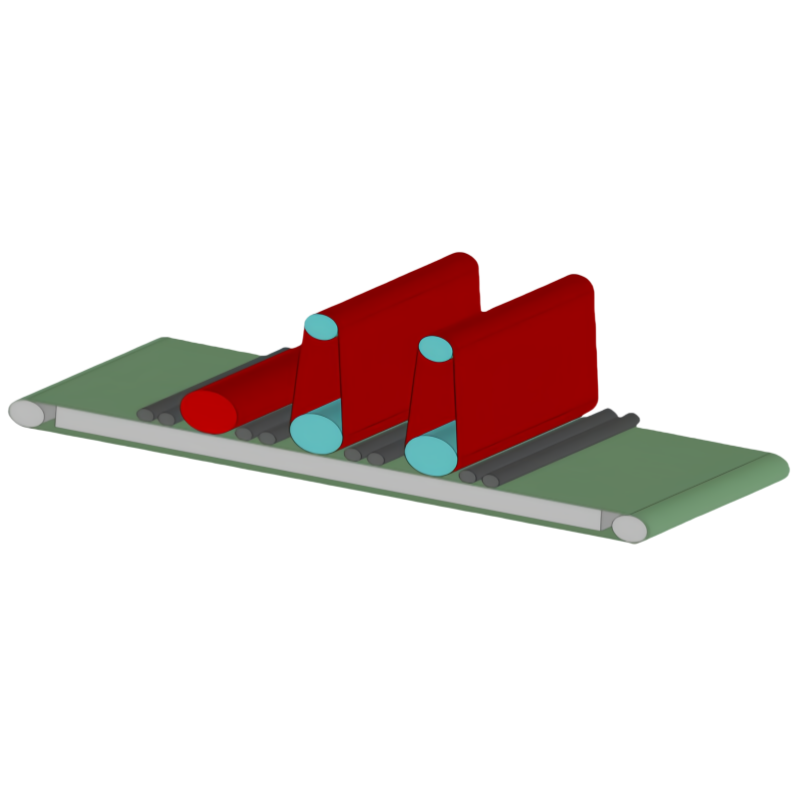

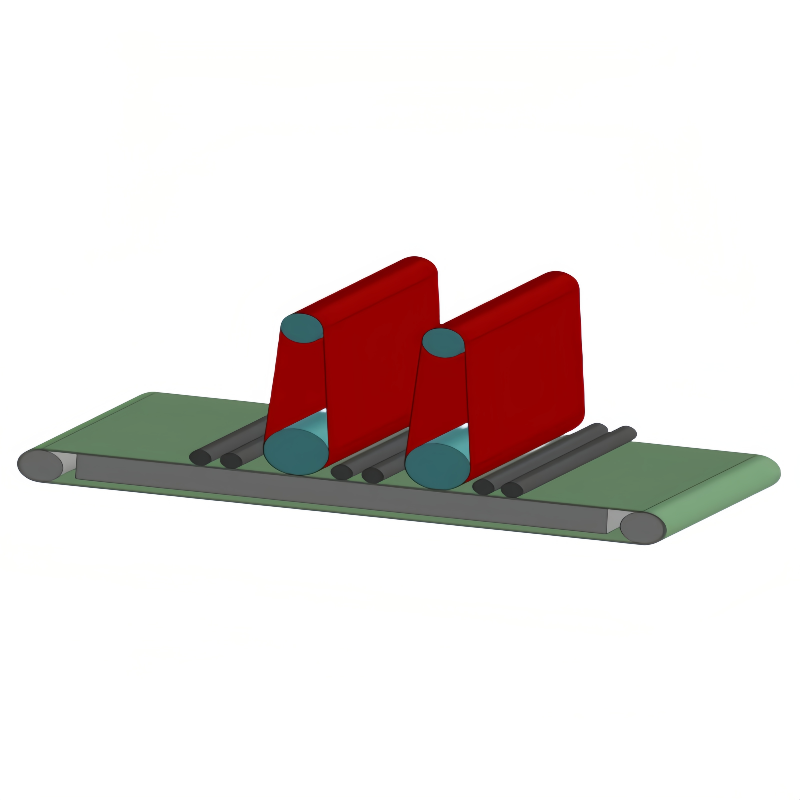

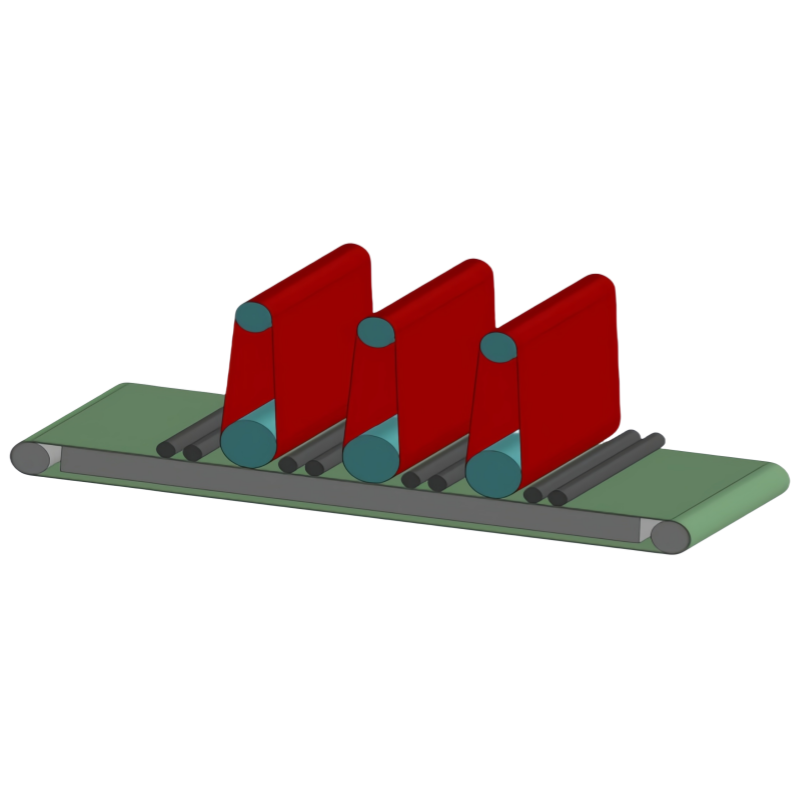

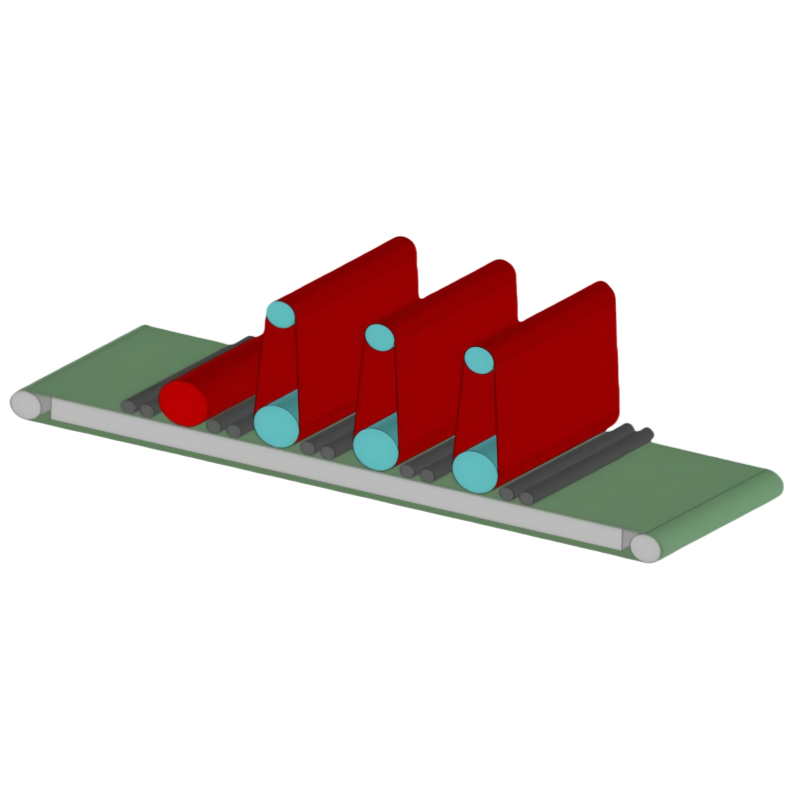

The Butfering Steel Master Series Wet Belt Sanders and Buffers are advanced industrial machines designed for high-precision metal surface treatment. These machines are perfect for various applications such as deburring, polishing, grinding, dross removal, edge radiusing, and more. Featuring a wide range of models, including the R5240, RR5240, RP5240, RRR5340, RRP5340, and RRRP5440, these machines come with several customizable features to meet the specific needs of different industries.

400 RRP Wet Belt Sander / Deburring Machine is an industrial-grade machine designed to efficiently handle metal surface finishing tasks, such as deburring, polishing, edge radiusing, and oxide removal. It is equipped with wet belt technology, providing superior results for various metalworking applications, including those in automotive manufacturing, precision engineering, and metal fabrication.

Key Features:

Wet Belt Technology: The machine operates using wet belt technology, which reduces heat buildup and minimizes dust during processing. This ensures that the metal parts remain cool and prevents thermal damage or warping during surface treatment.

Multiple Abrasive Belt Power Options: The PROFITINE 400 RRP is powered by high-performance abrasive belts:

The first abrasive belt motor is rated at 7.5 kW, allowing for powerful sanding and polishing of various metals.

Additional belt motors with 5.5 kW power provide further flexibility for different metal types and surface finishes.

Polishing Wheel: The machine features a powerful polishing wheel motor rated at 5.5 kW. This is ideal for achieving smooth, reflective surfaces on metal parts after the abrasive belt sanding process.

Magnetic Conveyor Table: The 400 RRP is designed with a magnetic conveyor table that holds the metal parts securely during the sanding and deburring process. This is particularly useful for processing thin or smaller components, ensuring consistent movement and precision.

Adjustable Settings for Belt Speed and Pressure: The machine offers adjustable settings to control the speed and pressure of the abrasive belts. This allows for customization based on the specific material and desired finish.

Deburring and Edge Radiusing: The machine excels at removing burrs from metal edges and provides edge radiusing functionality, rounding off sharp edges for improved safety and aesthetics.

Easy Operation and Maintenance: Designed for ease of use, the machine is equipped with a user-friendly interface for simple adjustments. Additionally, the wet process reduces maintenance needs related to dust accumulation, ensuring long-term reliability and minimal downtime.

Applications: Ideal for industries such as automotive, metalworking, aerospace, and construction, where precise metal surface finishing is required.

1. Models Overview:

| Specification | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm |

| Max Working Height | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| Min Working Length | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| First Abrasive Belt Power | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW |

| Second Abrasive Belt Power | - | 5.5 kW | - | 5.5 kW | 5.5 kW | 5.5 kW |

| Third Abrasive Belt Power | - | - | - | 5.5 kW | - | 5.5 kW |

| Polishing Wheel Power | - | - | - | - | 5.5 kW | 5.5 kW |

| Rotating Motor Power | - | - | - | - | - | - |

| Feed Motor Power | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Lift Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW |

| Swing Motor Power | - | - | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Vacuum Motor Power | - | - | - | - | - | - |

| Machine Dimensions (L×W×H) | 1.8×1.5×1.8 m | 2.1×1.5×1.8 m | 2.1×1.5×1.8 m | 2.4×1.5×1.8 m | 2.4×1.5×1.8 m | 2.7×1.5×1.8 m |

| Machine Weight | 1000 kg | 1200 kg | 1200 kg | 1500 kg | 1500 kg | 1800 kg |

| Abrasive Belt Size | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm |

Applications:

Automotive Industry: Used for deburring and polishing automotive parts such as body panels, engine components, and structural parts.

Metalworking and Fabrication: Suitable for deburring, polishing, and edge radiusing of metal parts used in industrial machinery and equipment.

Aerospace: Provides precise finishing for aerospace components, meeting stringent quality and tolerance requirements.

Construction Equipment: Ideal for large metal parts used in construction and heavy equipment.

Benefits:

High Efficiency: The combination of high-power abrasive belts and a polishing wheel provides fast, efficient processing with minimal operator effort.

Versatile Surface Finishing: Suitable for a wide range of applications, including deburring, edge radiusing, polishing, and oxide skin removal.

Dust and Heat Reduction: The wet belt system minimizes heat buildup and reduces airborne dust, contributing to a cleaner and safer work environment.

Customizable Settings: Adjustable settings for belt speed and pressure ensure flexibility to meet specific material and finish requirements.

Durable and Reliable: Built to last, the machine’s high-quality components and robust construction ensure long-term performance in demanding industrial environments.