Butfering Steel Master 400mm Wet Belt Sander / Buffer with Magnetic Conveyor Table

The Butfering Steel Master Series Wet Belt Sanders and Buffers are advanced industrial machines designed for high-precision metal surface treatment. These machines are perfect for various applications such as deburring, polishing, grinding, dross removal, edge radiusing, and more. Featuring a wide range of models, including the R5240, RR5240, RP5240, RRR5340, RRP5340, and RRRP5440, these machines come with several customizable features to meet the specific needs of different industries.

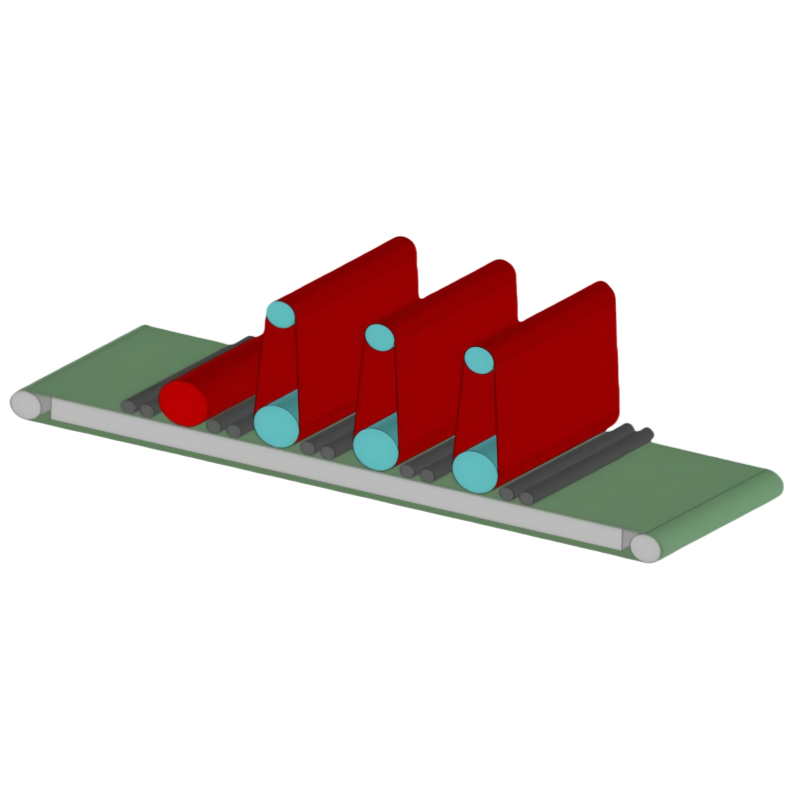

Metal Wet Wide Belt Sander "Wet Type" 4-Head Belt Sander/Finisher RRRP400C

The Metal Wet Wide Belt Sander "Wet Type" 4-Head Belt Sander/Finisher – Model RRRP400C is an advanced industrial machine designed for high-performance metal surface finishing. Whether you're working with carbon steel, stainless steel, aluminum, or other non-ferrous metals, this machine is optimized for wet sanding, deburring, edge radiusing, polishing, and dross removal. Equipped with four sanding heads, the RRRP400C delivers consistent, high-quality results for various metal processing applications.

This wet-type sanding system is designed to maximize productivity while ensuring superior surface finishes, making it ideal for industries such as automotive manufacturing, metalworking, aerospace, and engineering.

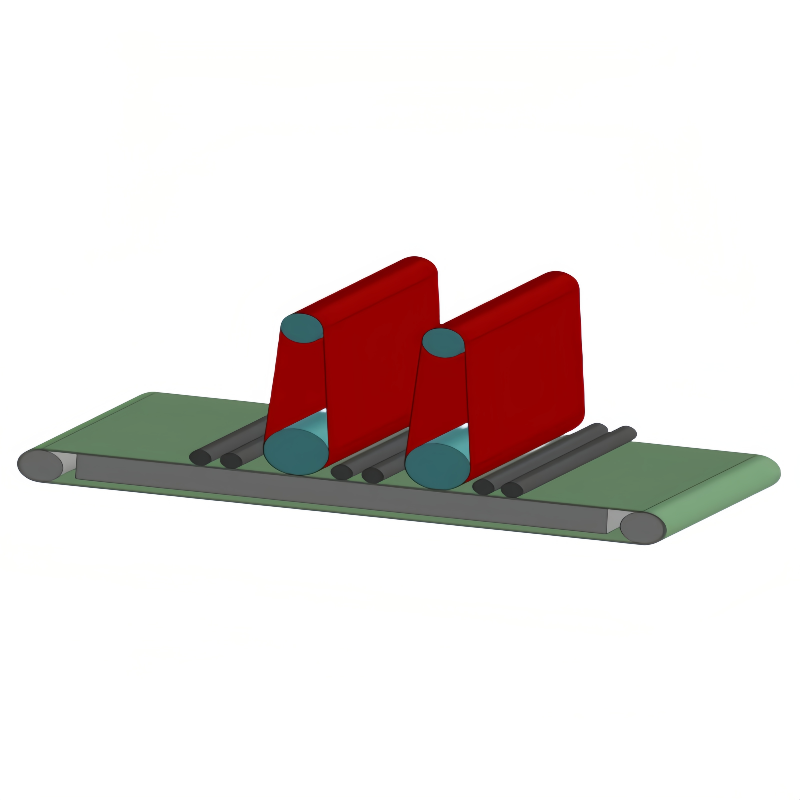

1. Models Overview:

| Specification | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm |

| Max Working Height | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| Min Working Length | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| First Abrasive Belt Power | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW |

| Second Abrasive Belt Power | - | 5.5 kW | - | 5.5 kW | 5.5 kW | 5.5 kW |

| Third Abrasive Belt Power | - | - | - | 5.5 kW | - | 5.5 kW |

| Polishing Wheel Power | - | - | - | - | 5.5 kW | 5.5 kW |

| Rotating Motor Power | - | - | - | - | - | - |

| Feed Motor Power | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Lift Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW |

| Swing Motor Power | - | - | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Vacuum Motor Power | - | - | - | - | - | - |

| Machine Dimensions (L×W×H) | 1.8×1.5×1.8 m | 2.1×1.5×1.8 m | 2.1×1.5×1.8 m | 2.4×1.5×1.8 m | 2.4×1.5×1.8 m | 2.7×1.5×1.8 m |

| Machine Weight | 1000 kg | 1200 kg | 1200 kg | 1500 kg | 1500 kg | 1800 kg |

| Abrasive Belt Size | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm |

Key Features

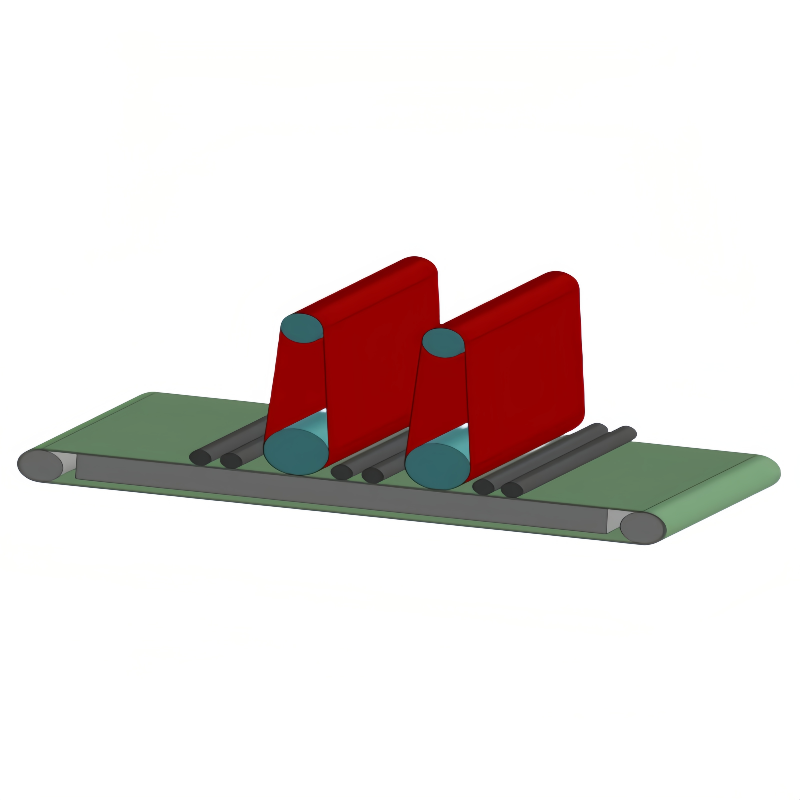

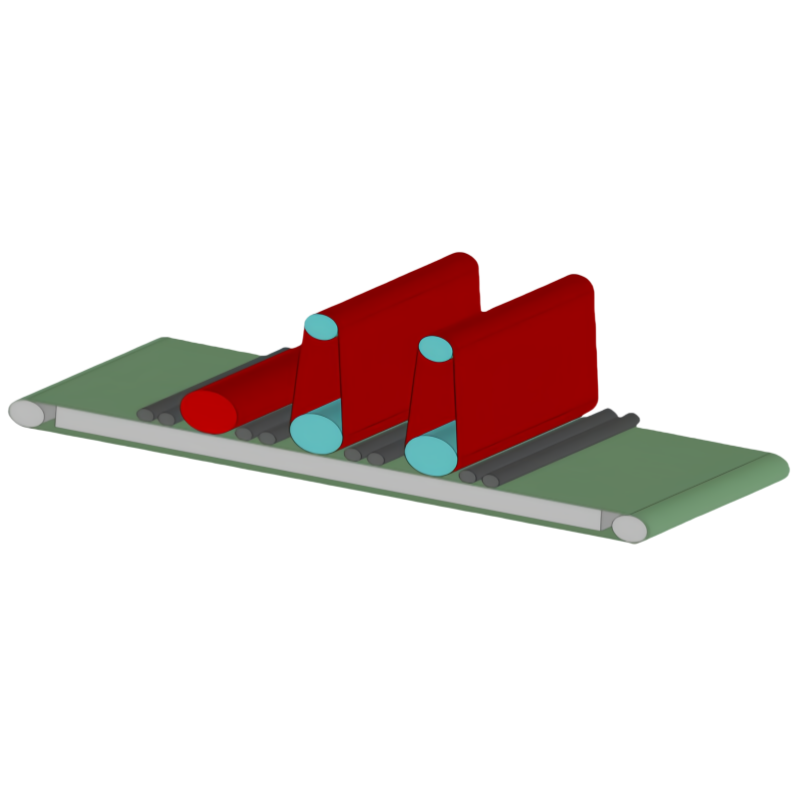

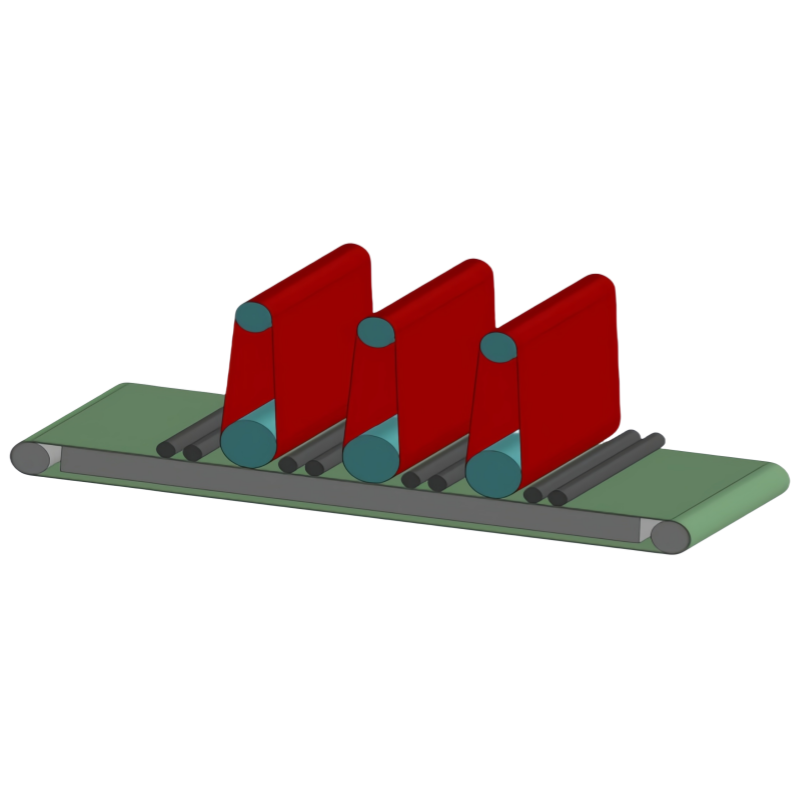

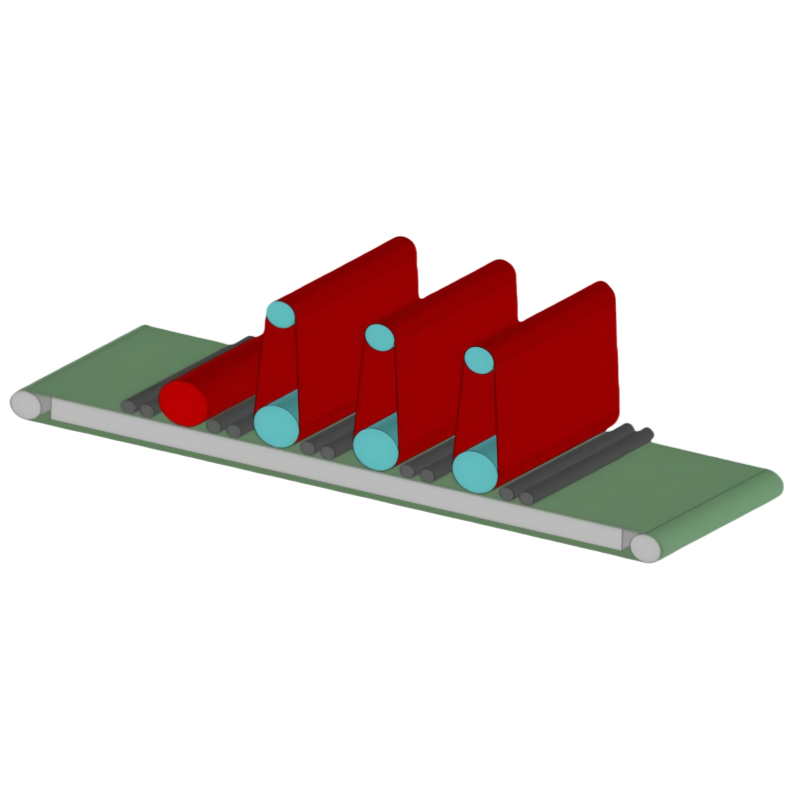

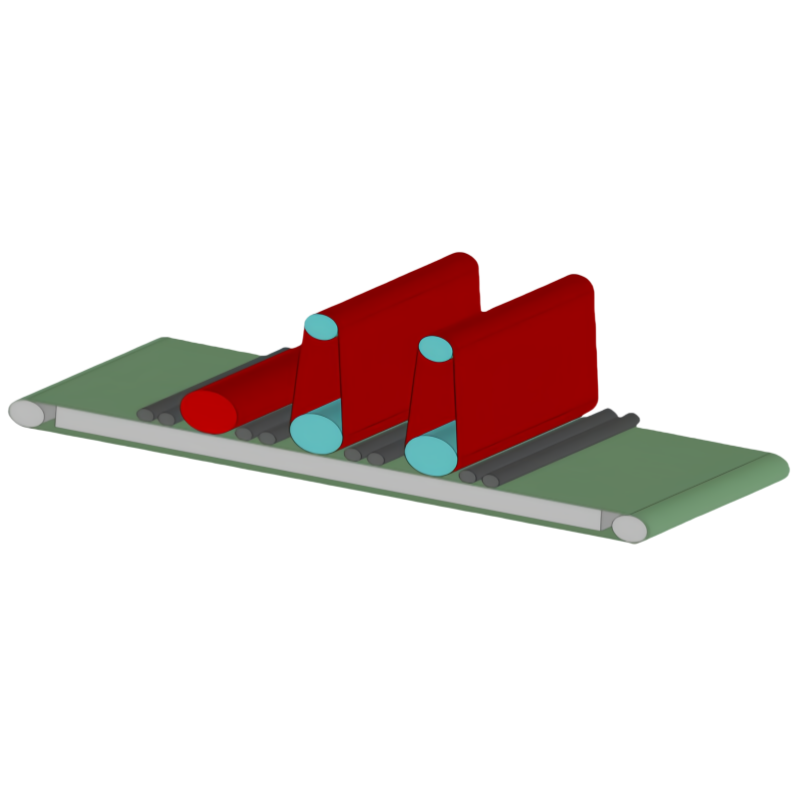

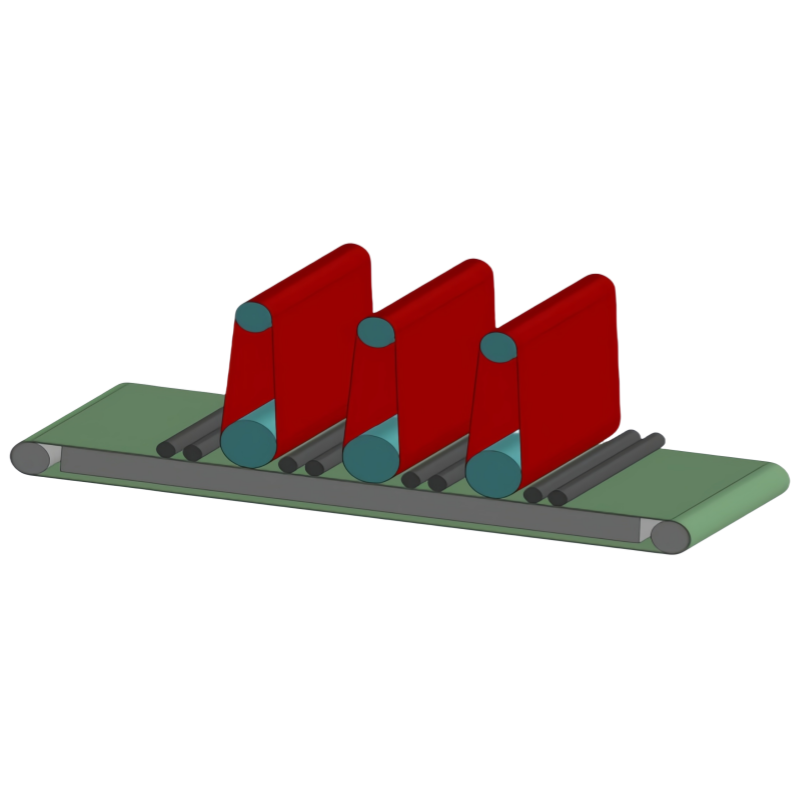

4-Head Sanding System: The RRRP400C features a 4-head belt sanding system, offering multiple stages of processing. Each sanding head can be equipped with different abrasive materials for coarse grinding, fine sanding, and polishing. The flexibility to adjust the sanding process ensures optimal results across a wide range of metal types and finishes.

Wet Sanding Technology: This wet-type system uses water or coolant during the sanding process to reduce heat buildup, minimize dust, and enhance the finish quality. Wet sanding results in a smoother finish with reduced friction, preventing material deformation and ensuring a high-quality, uniform surface on metal parts.

Magnetic Conveyor Worktable: The RRRP400C comes with a magnetic conveyor worktable, which securely holds metal workpieces during sanding. The magnetic system ensures stable positioning, preventing shifting or vibration that could affect the accuracy and quality of the sanding process.

Multiple Motorized Sanding Belts: With multiple sanding belt motors (up to 7.5 kW for the first sanding belt), the RRRP400C is capable of handling heavy-duty operations such as deburring, edge rounding, dross removal, and metal polishing. The powerful motors ensure efficient processing even for large or thick workpieces.

Adjustable Feed Rate: The machine offers variable feed rates, which can be easily adjusted to match the size and type of workpiece being processed. This flexibility allows the machine to handle a wide range of metal thicknesses and sizes with precision.

High-Precision Control System: Equipped with a PLC-based control system, the RRRP400C ensures consistent, precise control over sanding speed, belt tension, and workpiece thickness. This allows operators to make quick adjustments and ensures a consistently high level of finish quality.

Easy Maintenance and Operation: The RRRP400C is designed with ease of maintenance in mind. It features user-friendly controls, easy-to-access components for belt replacement, and a robust dust and coolant management system to keep the machine running efficiently over long periods.

Applications

Deburring: The wet belt sander excels in deburring metal workpieces after laser cutting, punching, or flame cutting. By removing rough edges and burrs, the machine prepares parts for subsequent processing or assembly.

Edge Radiusing: The machine is perfect for creating smooth, rounded edges on metal parts. The four-head sanding system ensures precise radiusing, ideal for parts that require both aesthetic and functional edge treatment.

Surface Finishing: The wet sanding process creates a fine, smooth finish on metal surfaces. Whether it's polishing, removing oxidation, or smoothing rough surfaces, the RRRP400C delivers a consistent, high-quality result that meets even the most demanding surface requirements.

Dross Removal: The wet sanding process is highly effective in removing dross from plasma cutting or laser cutting. It smooths and cleans the surface, making parts ready for further use or coating.

Polishing: The polishing head can be fitted with fine abrasive materials to achieve a high-gloss finish on metal parts. The wet system ensures that the final finish is smooth, uniform, and free from any scratches or imperfections.

Advantages

Superior Finishing Quality: The wet sanding process ensures a finer finish than dry sanding, making it ideal for parts that require a smooth, polished, or uniform surface.

Enhanced Workpiece Stability: The magnetic conveyor worktable holds metal parts securely during processing, reducing vibrations and ensuring consistent, high-precision results.

Reduced Heat Buildup: The wet sanding system minimizes heat buildup during sanding, preventing material distortion or burnishing, and extending the life of the abrasives.

Increased Productivity: With its powerful sanding motors and efficient wet sanding system, the RRRP400C can handle high-volume production tasks, improving throughput while maintaining quality.

Versatile Applications: The 4-head sanding system allows for multi-stage processing, making it suitable for a variety of tasks, including deburring, edge radiusing, polishing, and dross removal.

Low Maintenance Requirements: The design of the machine ensures easy maintenance, with quick access to parts for cleaning, belt replacement, and servicing.