Nitrogen Generation System for Laser Welding

High Purity • High Stability • Intelligent Control

Our ZHN Series Nitrogen Generators are specially designed for laser welding applications, providing stable, high-purity nitrogen with precise flow control. Built with advanced PSA (Pressure Swing Adsorption) technology, intelligent PLC control, and robust filtration, they ensure consistent protection of weld seams, oxidation prevention, and improved welding quality.

Key Features

High Purity Output: Adjustable nitrogen purity from 95% to 99.999% to suit various welding needs.

Steady Flow Rate: Multiple models available — 20 NL/min, 40 NL/min, 60 NL/min — to match different production capacities.

Intelligent PLC Control: Integrated 7-inch touch screen with multi-language support for easy operation.

Standard Triple Filtration System: Ensures ultra-clean nitrogen output by removing oil, dust, and moisture.

Automatic Drainage: Reduces manual maintenance and prolongs equipment lifespan.

Compact Design: Space-saving vertical structure, ideal for workshop environments.

Global Power Compatibility: AC 100–250 V, 50/60 Hz.

Applications in Laser Welding

Protective Atmosphere: Nitrogen shields the molten pool, preventing oxidation and discoloration.

Welding Quality Enhancement: Improves seam smoothness and strength.

Versatile Use: Compatible with handheld and automated laser welding machines in industries such as stainless steel fabrication, electronics, and precision instruments.

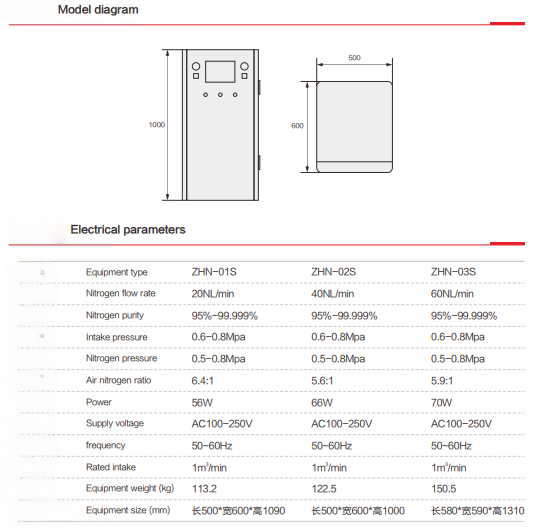

Electrical Parameters & Technical Specifications

| Model | Nitrogen Flow Rate | Nitrogen Purity | Intake Pressure | Nitrogen Pressure | Air:N₂ Ratio | Power | Voltage & Frequency | Rated Intake | Weight (kg) | Dimensions (mm) |

| ZHN-01S | 20 NL/min | 95%–99.999% | 0.6–0.8 MPa | 0.5–0.8 MPa | 6.4 : 1 | 56 W | AC 100–250 V, 50/60 Hz | 3 m³/min | 113.2 | 500×600×1090 |

| ZHN-02S | 40 NL/min | 95%–99.999% | 0.6–0.8 MPa | 0.5–0.8 MPa | 5.6 : 1 | 66 W | AC 100–250 V, 50/60 Hz | 3 m³/min | 122.5 | 500×600×1000 |

| ZHN-03S | 60 NL/min | 95%–99.999% | 0.6–0.8 MPa | 0.5–0.8 MPa | 5.9 : 1 | 70 W | AC 100–250 V, 50/60 Hz | 3 m³/min | 150.5 | 580×590×1310 |

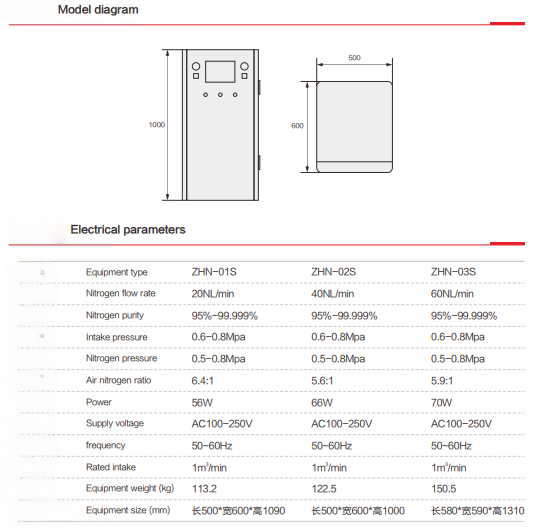

Model Diagram & Welding Effect

Model Diagram: Shows internal PSA adsorption columns, filtration system, and PLC control interface.

Welding Effect: Achieves bright, smooth, and oxidation-free weld seams, suitable for high-end manufacturing standards.