10-axis,4100mm CNC metal folding machine is a robust and versatile piece of equipment designed for high-precision bending and folding of metal sheets.

Large Bending Capacity

Bending Length: The machine has a bending capacity of up to 4100mm, allowing it to handle large sheets efficiently.

Material Thickness: Capable of bending various metal thicknesses, typically ranging from 0.5mm to 10mm, depending on the machine's specifications and the material used.

CNC Control System

Precision Control: Equipped with a CNC (Computer Numerical Control) system for precise and repeatable bending operations. The system allows for complex bend angles and shapes to be programmed easily.

User-Friendly Interface: The control panel typically features an intuitive interface, enabling operators to quickly set up and modify bending programs.

Specifications

Working Width: 4100 mm, allowing for larger sheets of metal.

Bending Capacity: Typically capable of bending materials up to 1.0 to 8.0 mm in thickness, depending on the type of material (e.g., stainless steel, aluminum).

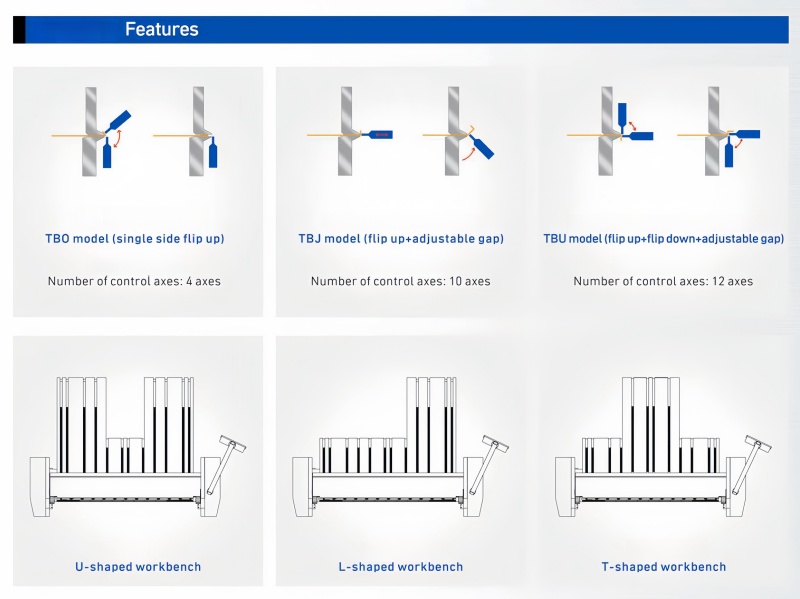

Axes: Often equipped with 4 to 10 axes, providing advanced control for complex bending profiles.

Bending Angle: Capable of achieving angles up to 180 degrees, with programmable settings for varying angles.

Back Gauge: CNC-controlled back gauge for precise positioning of the sheet metal.

Tooling: Quick-change tooling system for easy setup and adjustment.

Power Source: Hydraulic or electric drive system to ensure consistent performance.

Control System: Advanced CNC control with a user-friendly interface for programming multiple operations.

Safety Features: Emergency stop buttons, safety guards, and compliance with international safety standards.

The Gantry Loader with Suction Cup Frame is an advanced automation solution designed to enhance the efficiency and accuracy of loading metal blanks into production machines, particularly in environments where versatility and adaptability are crucial. Here’s a detailed overview of its features and functionalities:

Key Features

Suction Cup Frame

Versatile Suction Cups: The suction frame is equipped with suction cups of various sizes, allowing for adaptability to different blank dimensions and geometries.

Quick Locking Mechanism: Enables fast setup and repositioning of suction cups for maximum flexibility in handling various blank types.

Peeling Suction Cups: Designed with a large stroke height, these cups can separate the top blank from a stack, facilitating smooth production flow.

Double Material Detection System: Ensures that only a single blank is picked up at a time, minimizing errors and maintaining production integrity.

Intelligent Software Features

Adaptive Loading: The suction frame is capable of reliably loading blanks with different dimensions, geometries, and hole patterns, thanks to sophisticated software programming.

Spring-Mounted Suction Cups: These cups can accommodate variations in the floor surface, enabling them to lift blanks from uneven piles and handle those with slight embossings.

QR Code Scanner Integration

Program Recognition: The QR code scanner attached to the gantry loader reads the QR codes on each blank, automatically loading the corresponding program for the production process.

Automated Operation: After scanning, the suction frame lifts the top blank, checks for double sheets, and transfers the workpiece to the Multibend Center for further processing.

Robotic Blank Loading

Standard and Magnetic Loading: The intelligent loading robot uses a standard suction frame for blanks with closed base surfaces. For blanks with holes or cutouts, integrated magnets allow for effective loading, significantly increasing the range of blanks that can be automatically handled.

MiniFeeder System

Multi-Blank Loading Capability: The MiniFeeder is designed for efficiently loading different blanks from a single stack. For example:

Elevator Panel Production: Can handle kits for 10 elevators, each with 9 panels. The scanner reads the barcode label on each blank to load the correct program.

Ceiling Panel Loading: Utilizes 12 oval suction cups to handle perforated blanks with small borders.

Active Suction Cup Configuration: The number of active suction cups adjusts based on the blank width, ensuring optimized loading efficiency.

Material Thickness Check: Integrated checks ensure that the correct material thickness is being handled before processing.

Connection to Robotic Loading

Applications

Applications

This type of CNC metal folding machine is commonly used in industries such as:

Automotive: Manufacturing parts like brackets, frames, and enclosures.

Aerospace: Producing high-precision components for aircraft.

HVAC: Creating ductwork and fittings.

Metal Fabrication Shops: General-purpose bending and folding for custom projects.

Electrical Enclosures: Designing cases and boxes for electronic equipment.

Construction: Producing structural components and architectural elements.

Recommended Brands

When considering a 4100mm CNC metal folding machine, look for reputable manufacturers such as:

Amada

Trumpf

Bystronic

LVD

EHT

Technical Parameter

| Item | Unit | TB025 | TB032 | TB041 | TBJ25 | TBJ32 | TBJ41 | TBU25 | TBU32 | TBU41 |

| Bending thickness (carbon steel) | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Bending thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending angle range | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | -45...+45 | -45...+45 | -45...+45 |

| Max. bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Rear positioning length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Open height | mm | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Bending tool height | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| Control axis number |

| 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Pressing speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Bending speed | m/s | 5.0 | 5.0 | 5.0 | 6.5 | 6.5 | 6.5 | 7.0 | 7.0 | 7.0 |

| Motor energy consumption | kW | 3.5 | 4.5 | 6.1 | 3.5 | 4.5 | 6.1 | 5.5 | 7.0 | 10.0 |

| External dimensions (L × W × H) | mm | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5700×2150 |

| Weight | kg | 4500 | 5300 | 7500 | 4500 | 5300 | 7500 | 4900 | 7000 | 11000 |

This table provides information on various models of CNC sheet metal folding machines, highlighting their specifications such as bending thickness, bending angle range, maximum bending length, open height, speed, motor energy consumption, dimensions, and weight.

Recommended Models:

Some well-regarded brands that manufacture high-quality CNC sheet metal folding machines include:

Amada: Known for advanced technology and high-quality machines suitable for various bending applications.

Trumpf: Offers innovative solutions and robust machines for efficient sheet metal processing.

Bystronic: Features user-friendly interfaces and reliable performance for bending and folding tasks.

EHT: Provides a range of CNC folding machines with customizable features to meet specific production needs.

Applications:

CNC folding machines are widely used in industries such as:

Automotive manufacturing

Aerospace components

HVAC systems

Electrical enclosures

Furniture manufacturing

Applications

Applications