Introduction to the AC220/380V Sheet Metal Vacuum Lifting Device for Handling Sheets of Metal, Glass, and Other Materials (Rechargeable)

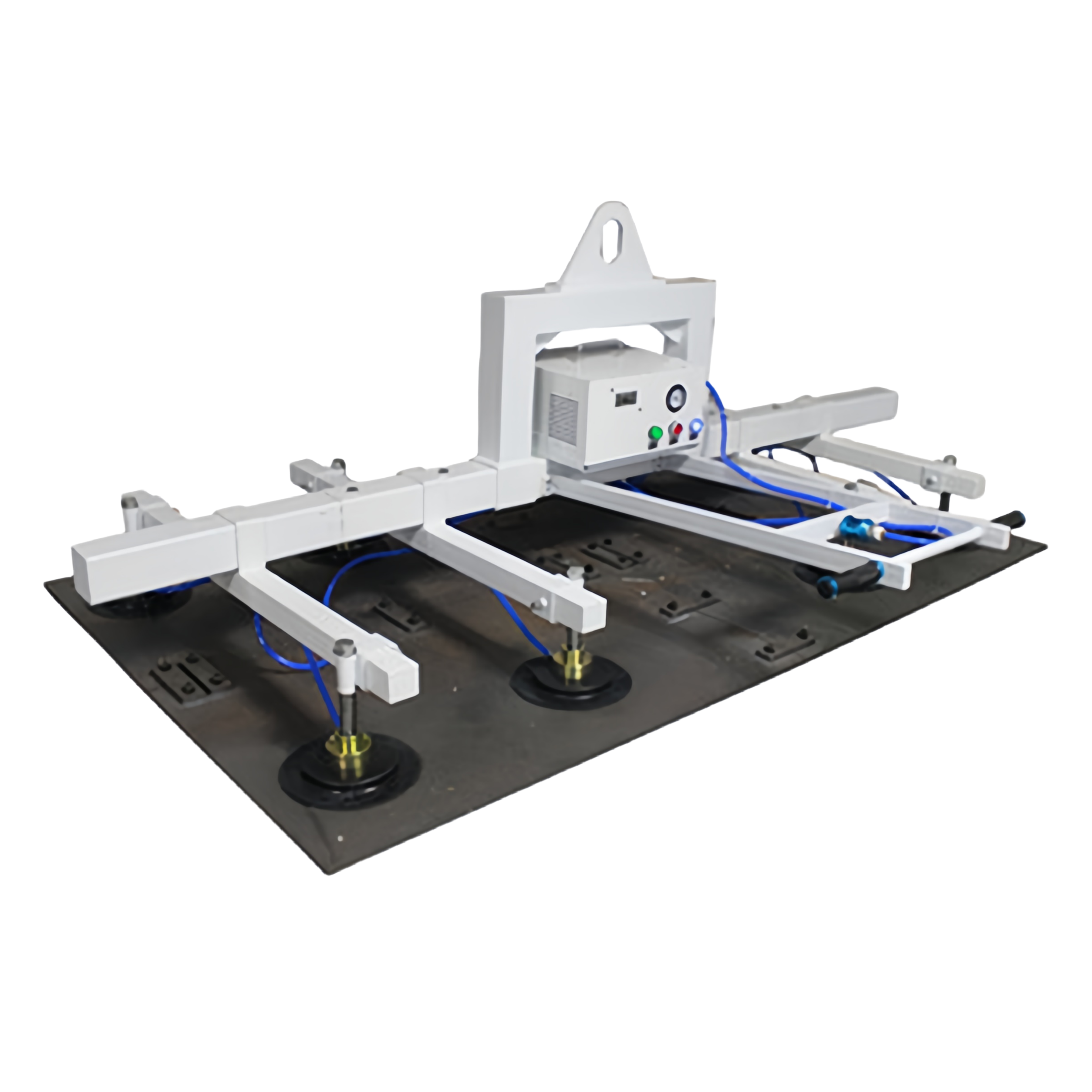

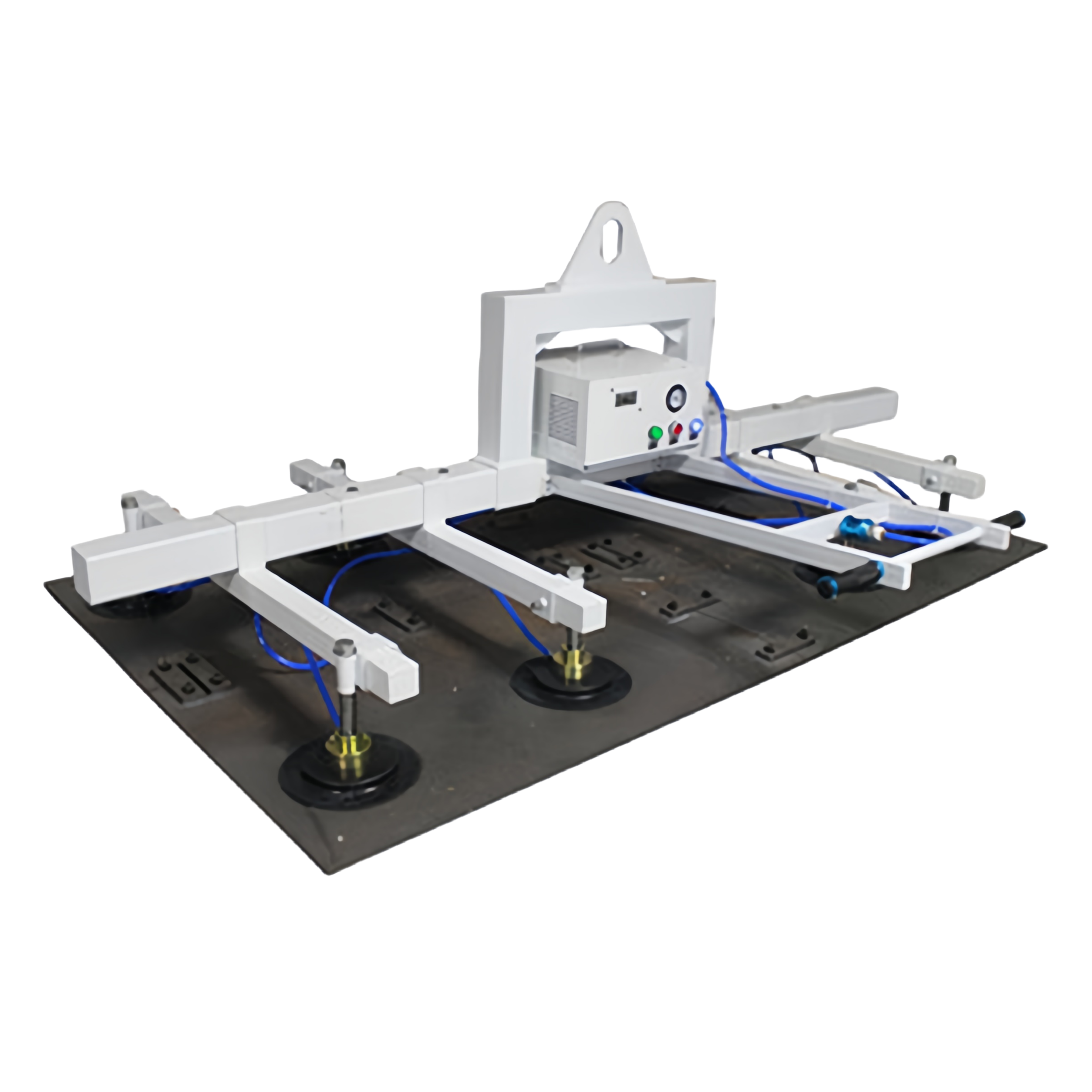

The AC220/380V Sheet Metal Vacuum Lifting Device is an advanced and versatile lifting solution designed for the efficient handling of heavy metal sheets, glass panels, and other materials across industrial settings. Featuring rechargeable battery technology, this lifter combines the reliability of AC220/380V power supply with the flexibility of battery operation, making it an ideal tool for various manufacturing, construction, and warehousing applications.

This device is engineered to lift and transport large, heavy sheets—whether they are made of steel, aluminum, glass, or composite materials—with precision and safety. Capable of handling weights up to several hundred kilograms, the vacuum lifting system provides secure and efficient material handling, reducing the risk of damage, improving productivity, and enhancing workplace safety.

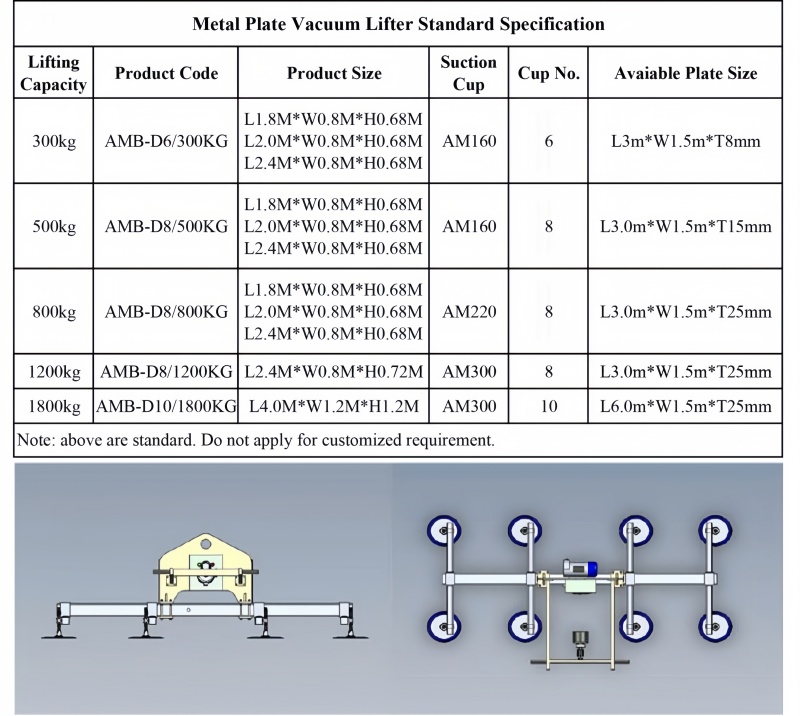

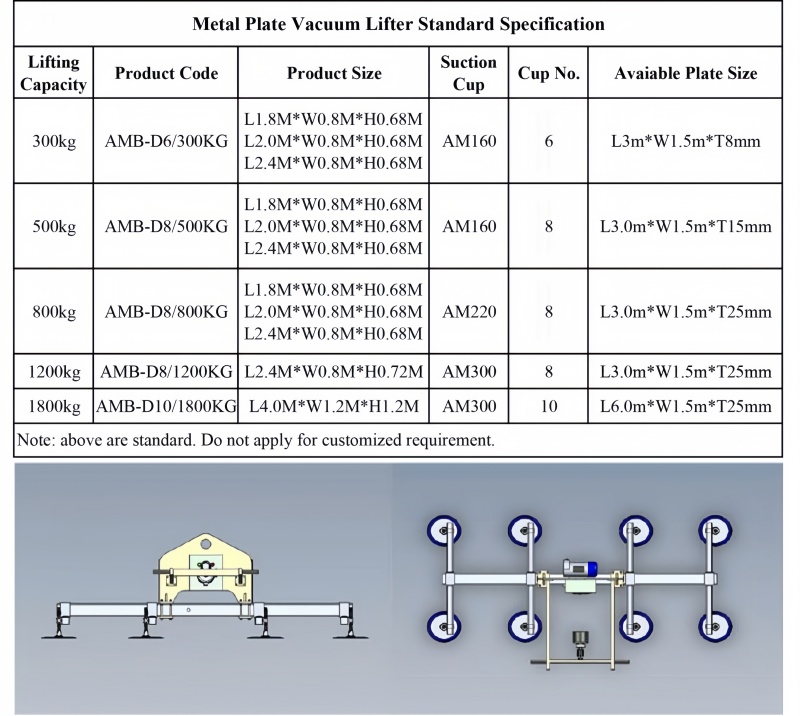

| Product Type | Rechargeable Lifter | Plug-in Lifter |

| Model | JS-J1000-5M | JS-J2000-5M | JS-C1000-25M | JS-C2000-5M |

| Rated Load (kg) | 1000 | 2000 | 1000 | 2000 |

| Suction Cup Diameter (mm) | 200 | 200 | 200 | 200 |

| Number of Suction Cups | 12 | 12 | 12 | 12 |

| Dimensions (mm) | 5000*1000 | 5000*1000 | 5000*1000 | 5000*1000 |

| Plate Size (mm) | 6000*2000 | 6000*2000 | 6000*2000 | 6000*2000 |

| Operating Power (V) | DC12V | DC12V | AC220V/380V | AC220V/380V |

Key Features of the AC220/380V Sheet Metal Vacuum Lifting Device

1. Dual Power Supply (AC220/380V + Rechargeable Battery)

The lifting device is equipped with dual power supply options for enhanced versatility. It can be powered by AC220V/380V, ensuring continuous operation in facilities with access to a standard industrial power supply. However, the rechargeable battery option provides flexibility and portability for jobs that require moving the lifter between different stations or areas without direct access to power outlets.

AC220/380V Power Supply: The lifter operates with high power when connected to the industrial AC supply, ideal for environments where continuous operation is necessary, such as in large factories or metal fabrication plants.

Rechargeable Battery: The battery-powered option allows the lifter to be used in remote locations, construction sites, or areas without direct access to power, enhancing its mobility and operational flexibility. The long-lasting rechargeable battery ensures that the system remains operational for extended periods before requiring recharging.

2. Vacuum Lifting Technology for Secure Handling

At the core of this lifter is its vacuum lifting system, which uses powerful suction pads to securely grip and lift heavy materials such as metal sheets, glass panels, and other large, flat items. This technology ensures that the materials are held firmly in place during transport, eliminating the risks associated with manual handling and reducing the chances of damage to sensitive surfaces.

High Suction Power: The vacuum system provides a high level of suction power, ensuring that large sheets of metal, glass, or other materials can be lifted and moved safely without slipping or detaching.

Adjustable Suction Cups: The suction cups are designed to accommodate a range of sheet sizes and material types, making the system versatile and adaptable to different handling requirements. The suction pads can be adjusted to match the dimensions of the material being lifted, ensuring a secure hold.

Non-Damaging Handling: The vacuum suction method ensures that delicate materials, such as glass sheets, are handled without scratching, cracking, or damaging the surfaces. This is especially important in industries like construction, glass fabrication, and metalworking, where material integrity is crucial.

3. High Load Capacity and Heavy Material Handling

The AC220/380V Sheet Metal Vacuum Lifting Device is designed to handle heavy loads with ease. Depending on the specific model, this lifter can handle weights ranging from several hundred kilograms to over a ton, making it suitable for a variety of heavy-duty applications.

Lifting Capacity: The device is capable of lifting metal sheets or glass panels with weights ranging from 200kg to 1,000kg or more, depending on the configuration. It can handle large steel plates, aluminum panels, glass sheets, and other composite materials efficiently.

Heavy-Duty Construction: Built to withstand the stresses of lifting large, heavy items, this lifter is designed for industrial environments. Its durable construction ensures long service life and reliable operation under demanding conditions.

4. Ergonomically Designed for Safe and Easy Handling

One of the key advantages of the vacuum lifting device is its ergonomic design, which allows operators to lift and move heavy materials with minimal physical effort, reducing the risk of musculoskeletal injuries and improving worker safety.

Easy to Operate: The lifter is equipped with user-friendly controls that make it simple for operators to raise, lower, and transport materials. The intuitive control panel and simple interface reduce operator training time and ensure smooth operation.

Lightweight and Maneuverable: Despite its heavy-duty lifting capabilities, the lifter is designed to be lightweight and easy to maneuver. It can be operated with one or two people, depending on the material and environment, and is well-suited for tight spaces or high-traffic areas.

Reduced Worker Strain: By using vacuum technology, the lifter significantly reduces the physical effort required to lift and transport heavy materials, helping to prevent fatigue and strain injuries.

5. Energy-Efficient and Cost-Effective

This lifting device is designed with energy efficiency in mind. The AC220/380V power supply ensures reliable, high-power operation when connected to the electrical grid, while the rechargeable battery option provides the flexibility to move the lifter without relying on external power sources.

Energy Savings: The lifter's design is optimized to minimize energy consumption while maintaining a high level of performance. This is particularly important for companies looking to reduce operating costs and improve the sustainability of their material handling processes.

Low Maintenance: The vacuum lifting system requires minimal maintenance. Regular checks on the suction pads and battery performance help ensure reliable operation and extend the lifespan of the equipment.

6. Wide Range of Applications

This versatile vacuum lifter is suitable for a variety of industries and applications, including:

Metalworking and Fabrication: In metal fabrication shops, the lifter can be used to move large sheets of steel, aluminum, or copper between processing machines like laser cutters, press brakes, and welding stations.

Glass Handling: In the glass industry, this lifter provides a safe and reliable method for lifting and transporting glass sheets, windows, and glass panels without the risk of damage or breakage.

Construction: In construction and building applications, the lifter is ideal for moving large metal panels, glass windows, and pre-fabricated components.

Automotive Manufacturing: In automotive manufacturing, it can be used to lift and move large panels, car body parts, or components in assembly lines.

Warehousing and Logistics: The vacuum lifter is also ideal for warehousing, where heavy materials need to be lifted and transported between storage areas and production stations.

7. Advanced Safety Features

The AC220/380V Sheet Metal Vacuum Lifting Device comes equipped with several advanced safety features to protect both operators and materials:

Vacuum Pressure Monitoring: The system continuously monitors vacuum pressure to ensure that the suction remains at safe levels. If the vacuum level drops below a predetermined threshold, an alarm is triggered, warning the operator to take corrective action.

Emergency Stop Function: The lifter includes an emergency stop button, which allows the operator to halt all functions immediately in case of an emergency or malfunction.

Locking Mechanism: Once the material is securely lifted, the vacuum suction cups lock into place to prevent accidental detachment during transport, providing additional safety during operation.

Non-Slip Suction Pads: The suction cups are made of non-slip, durable materials that provide a reliable grip, even when handling large or heavy materials.

8. Low Maintenance and Durability

The AC220/380V Sheet Metal Vacuum Lifting Device is designed to be low-maintenance while offering high durability. With its industrial-grade components, the lifter is built to withstand the rigors of daily use in manufacturing, warehousing, and construction environments.

Durable Construction: The device is made with high-quality materials that resist wear and tear, even in harsh conditions. The vacuum pump, suction cups, and frame are designed for long-lasting performance.

Minimal Maintenance Requirements: Routine checks on the vacuum pump, suction pads, and battery are all that is needed to keep the lifter operating at peak efficiency. The system is designed for easy maintenance and repairs, reducing downtime and ensuring continuous operation.

Applications of the AC220/380V Sheet Metal Vacuum Lifting Device

The AC220/380V Sheet Metal Vacuum Lifting Device is perfect for a variety of industries that handle heavy, large-format materials:

Metalworking: Moving metal plates between cutting, welding, or punching stations.

Glass Industry: Lifting and transporting glass sheets or panels for glazing applications.

Construction: Moving large metal sheets or glass panels for use in building facades, windows, or structural elements.

Automotive Manufacturing: Lifting heavy body parts or large components during assembly.

Logistics and Warehousing: Transporting large materials between storage areas and production lines.