AC220V/380V Electric Vacuum Lifter for Lifting 600kg Wooden and Metal Boards, Panels, Doors, and Sheets with Vacuum Cups

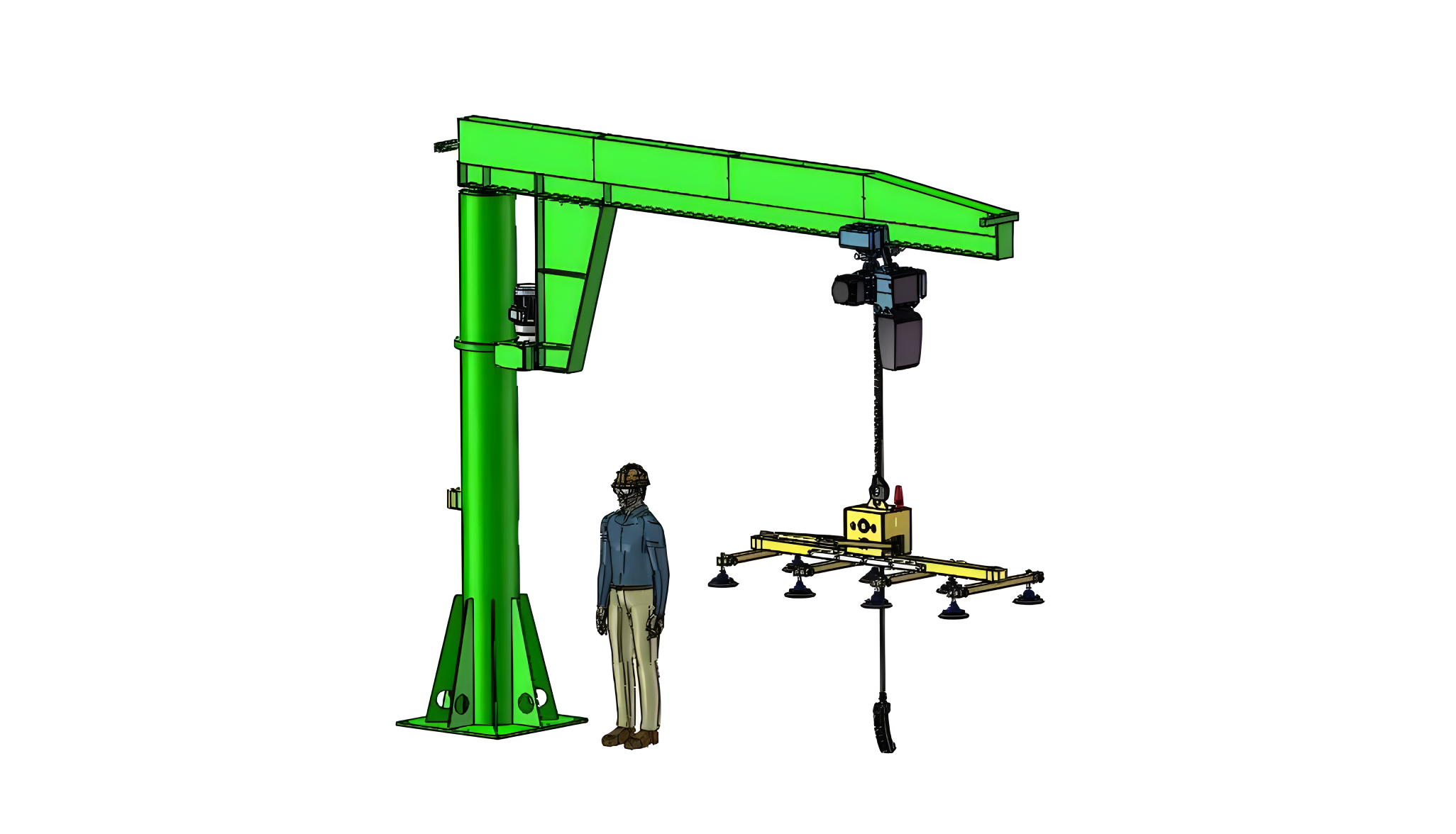

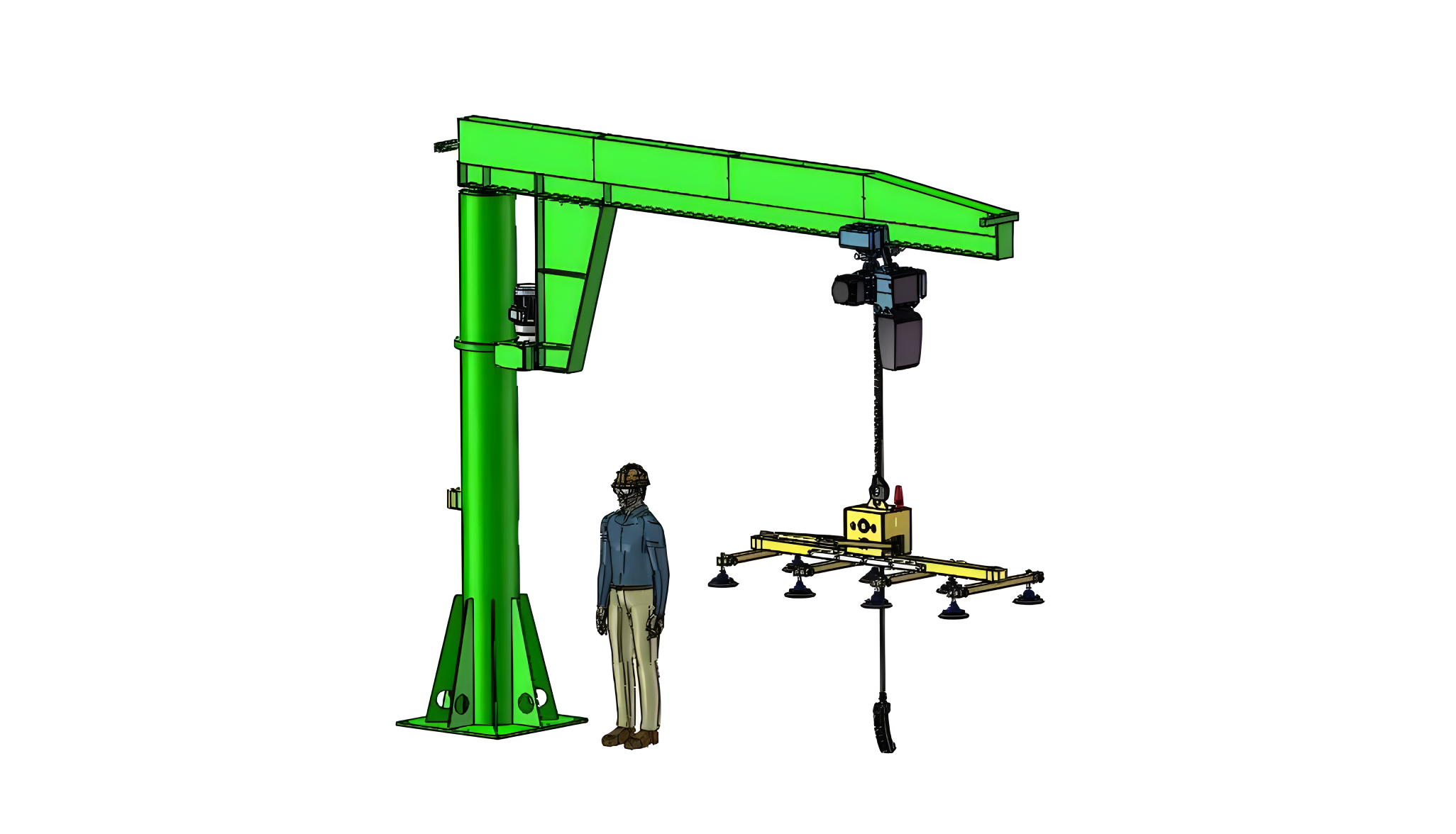

The AC220V/380V Electric Vacuum Lifter is a powerful and versatile lifting solution designed for safely and efficiently handling 600kg wooden and metal boards, panels, doors, and sheets. This vacuum lifter is ideal for use in a wide range of industries, including construction, manufacturing, woodworking, metalworking, and warehouse operations. The lifter uses advanced vacuum technology with specialized vacuum cups to securely lift and position large and heavy materials with ease.

Key Features:

Lifting Capacity:

Capable of lifting and placing materials weighing up to 600kg.

Designed to handle a variety of large and heavy materials, including wooden boards, metal panels, doors, and sheets.

Can lift a wide range of materials in various industries, ensuring versatility for different applications.

Voltage Options (220V and 380V):

Available in AC220V or AC380V models to accommodate different power supply requirements in various industrial settings.

The AC220V version is ideal for smaller-scale operations, while the AC380V model provides more power for large-scale, high-demand environments.

Electric Vacuum Pump:

Electric vacuum pump generates a powerful and consistent suction to securely hold materials, ensuring they remain stable during lifting and transportation.

The system maintains a steady vacuum level to lift and place wooden and metal boards, panels, doors, and sheet materials reliably.

Electric-powered system is more energy-efficient and provides precise control compared to pneumatic or hydraulic alternatives.

Versatile Vacuum Cups:

Equipped with customizable vacuum cups designed to accommodate different shapes, sizes, and materials, including flat wooden boards, metal panels, and sheet materials.

Specialized vacuum cups can be adjusted to fit the surface of different materials, providing secure grip and minimal risk of damage to delicate surfaces (like doors or metal panels).

Multiple vacuum cup configurations allow for flexible material handling, making the lifter adaptable to various lifting tasks.

User-Friendly Control System:

The intuitive control panel allows operators to easily control suction, lifting, and positioning of materials.

Includes features such as suction strength adjustment, tilt, and rotation functions to ensure precise placement of materials.

Ergonomic design reduces the physical strain on operators, making it ideal for repetitive tasks.

Durable Construction:

Built with high-strength materials to ensure durability and long-lasting performance, even under demanding lifting conditions.

Suitable for heavy-duty applications, it can withstand the physical demands of lifting 600kg materials.

Safety Features:

Equipped with vacuum monitoring systems to alert operators in case of a drop in suction levels, ensuring materials are securely held at all times.

Emergency stop buttons and overload protection prevent accidents and ensure safe operation.

Fail-safe mechanisms in the vacuum system ensure materials do not fall if there is a sudden loss of vacuum.

Efficient Material Handling:

Ideal for woodworking, metalworking, construction, and manufacturing industries that require lifting and placing large panels, doors, and boards.

Improves productivity by allowing one operator to handle large materials that would otherwise require multiple people.

Energy Efficiency:

Applications:

Woodworking Industry: Lifting and handling wooden panels, doors, and boards in manufacturing, construction, and installation processes.

Metalworking Industry: Moving metal sheets, panels, and metal doors with ease, making it suitable for fabrication, manufacturing, and assembly lines.

Construction and Manufacturing: Transporting large boards and panels for installation, handling heavy sheet materials, or lifting doors and other large components during building and renovation.

Warehouses: Handling large volumes of materials like wooden sheets or metal panels, especially during shipping, storage, or unloading.

Safety and Maintenance:

Vacuum Monitoring Systems: The lifter comes with built-in vacuum sensors to continuously monitor suction levels, providing safety warnings in case of any issues.

Low Maintenance: Due to its electric operation, the vacuum lifter requires less maintenance than hydraulic or pneumatic systems, reducing downtime and operational costs.

Emergency Features: The emergency stop button, vacuum failure alarm, and overload protection ensure the operator's safety and protect the lifter from damage.

Vacuum Lifter

| Product Model | JS-CG300-2M/3M | JS-CG600-2M/3M | JS-CG800-2M/3M |

| Rated Load (kg) | 300 | 600

| 800 |

| Suction Cup Diameter (mm) | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 6 | 8 |

| Outer Dimensions (mm) | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 |

| Plate Dimensions (mm) | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 |

| Working Voltage | AC220V/380V | AC220V/380V | AC220V/380V |

Typical Equipment Applications:

Sheet Metal Processing Industry: Primarily used for loading and unloading sheets in laser cutting, stamping, bending, and other processes.

Metal Processing Plants: Suitable for bulk handling and stacking of metal sheets, especially during long-term, high-frequency operations, where automated equipment can effectively reduce errors and waste.

Home Appliance Manufacturing: Automated handling equipment can be used for transporting materials like refrigerator, washing machine, and air conditioner shells, enhancing the level of automation in production lines.

Automotive Manufacturing: In the processing of automotive body panels, automatic stacking and handling equipment ensures the safe transport of large sheet metal parts.