1. Main Processing Range

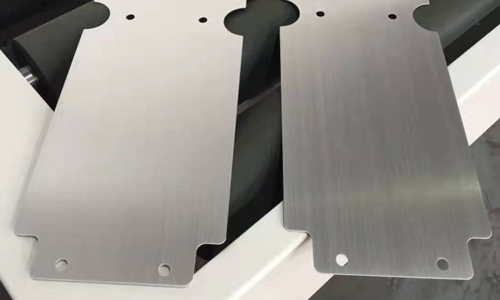

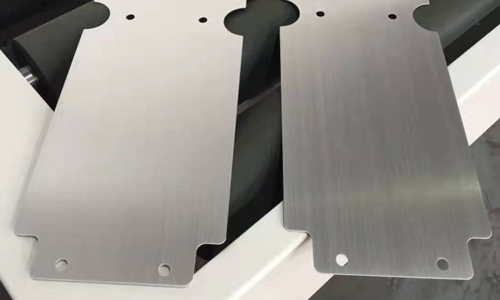

1.1 Processed Products: Carbon steel, stainless steel, aluminum plates, copper plates, and various non-ferrous metals.

1.2 Equipment Functions:

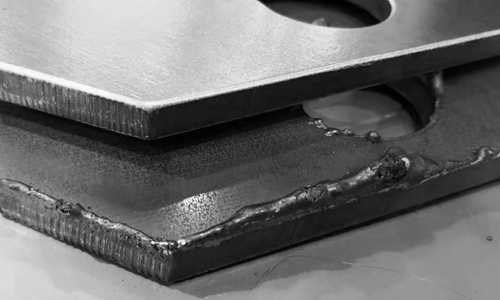

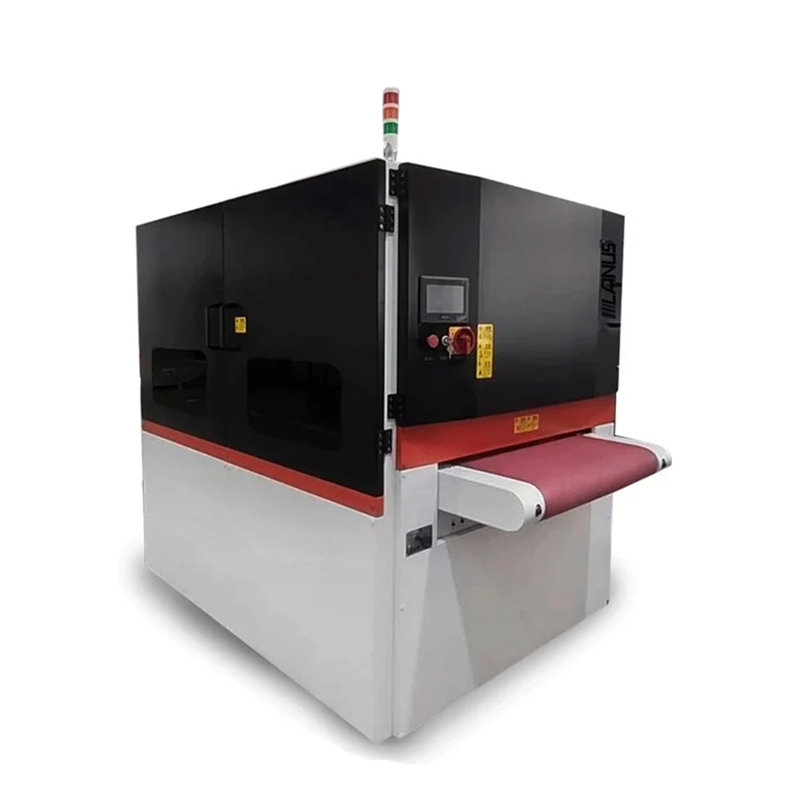

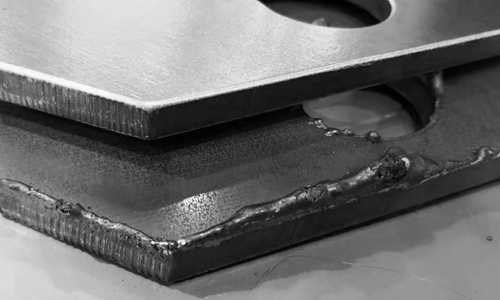

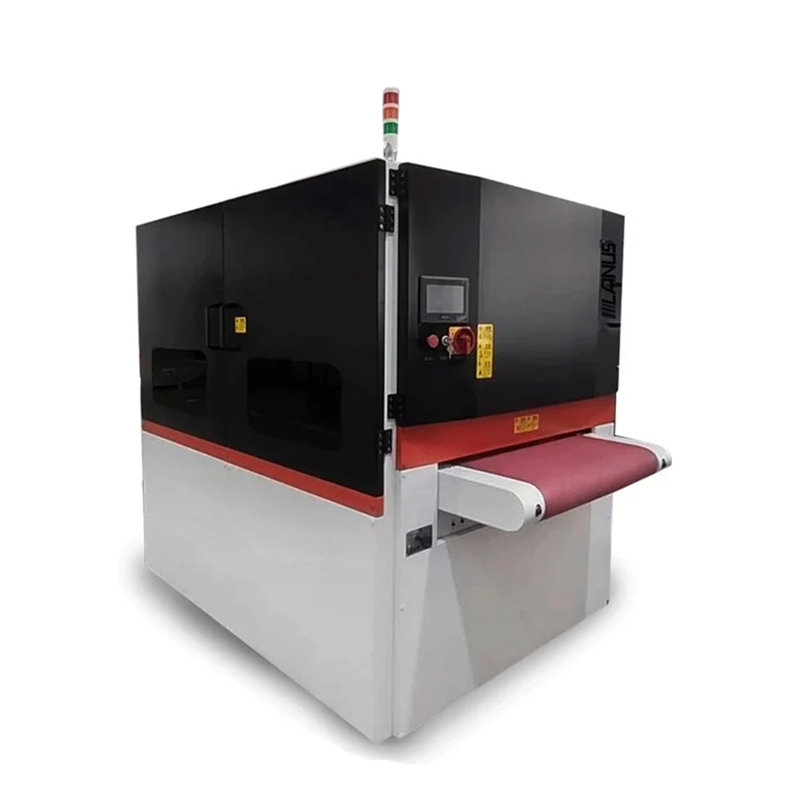

This equipment is a dry-type machine with four sets of universal sanding roller brushes. It is primarily used to handle deburring and edge rounding for metal workpieces, especially to remove burrs from the edges and holes formed during processes such as stamping, shearing, and laser cutting. The machine can effectively remove small burrs in one pass, ensuring that all edges and holes of the workpieces achieve a smooth, small R radius. The process is safe and reliable, ensuring that the workpieces meet perfect quality standards.

2. Equipment Working Principle

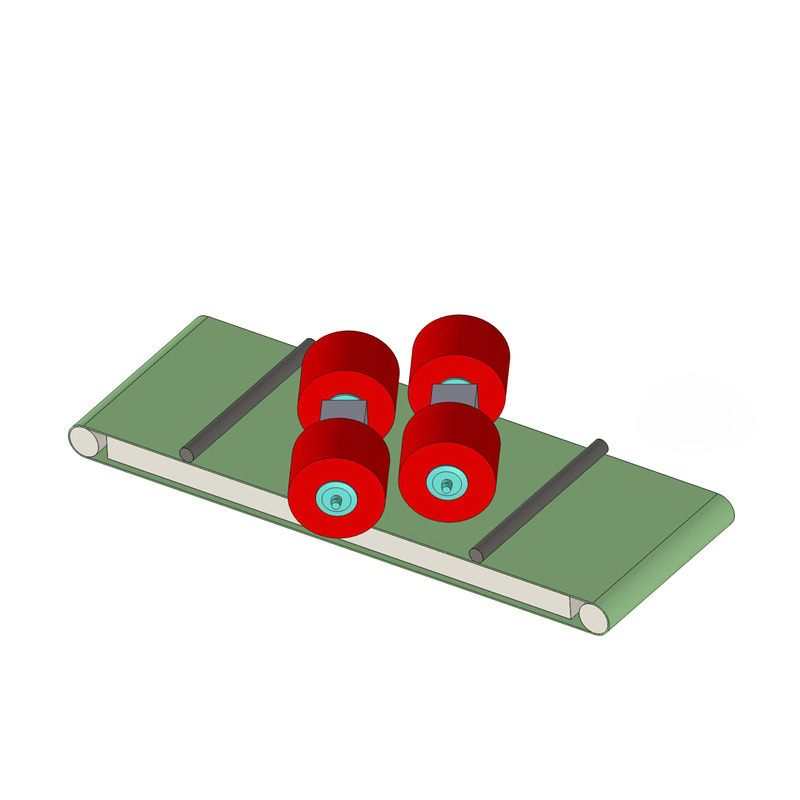

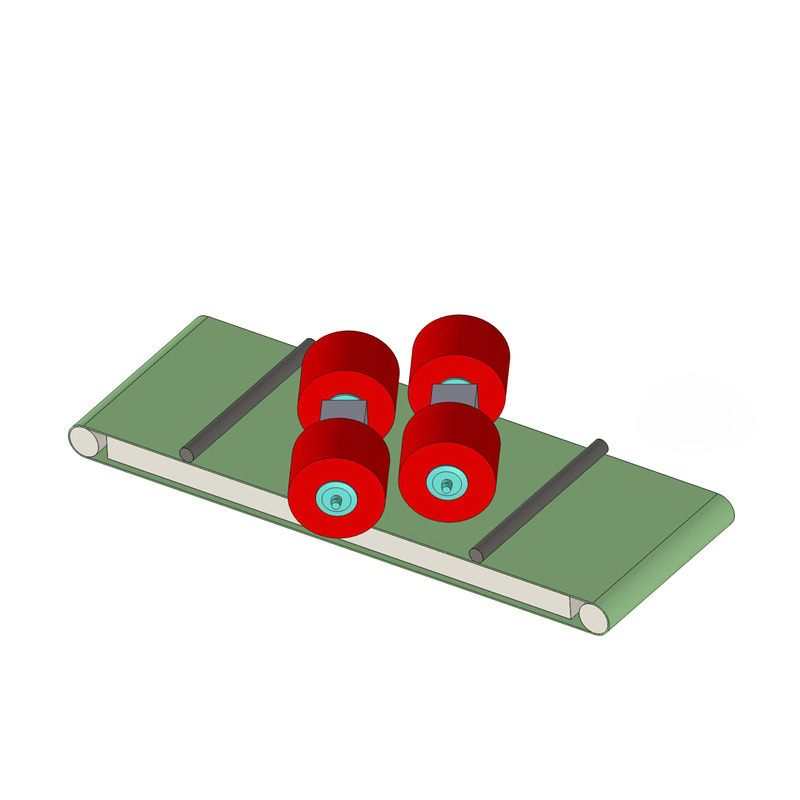

This machine uses four sets of universal sanding roller brushes. The adjacent brushes rotate in opposite directions, and their combined motion creates centrifugal forces that perform deburring, polishing, scraping, and smoothing of the edges and inner holes of the workpieces. The process ensures no dead spots and removes burrs while maintaining the precision of the workpiece dimensions.

The edge and hole burrs are completely removed, and a uniform R angle is created. The size of the R angle can be adjusted by selecting different processes and abrasives. The continuous processing does not affect the dimensional accuracy of the workpieces. This machine is particularly effective for laser-cut parts and CNC-punched parts with film coatings, ensuring burr removal without damaging the film or scratching the sheet metal.

Due to the use of special soft abrasive materials designed specifically for deburring, the machine can work on coated or non-coated metal workpieces without causing damage to their surfaces.

The conveying system uses powerful vacuum adsorption to secure workpieces. For parts larger than 50mm × 50mm (non-hollow workpieces), the machine can process without the need for additional fixtures. Special parts may require customized fixtures for fixed processing. The system also offers variable-speed control.

Wet dust extraction system: This reduces safety risks and efficiently processes grinding dust. A high-pressure, high-flow fan at the top of the machine draws grinding dust into a dust chamber, where water spray causes the dust to settle. The dust is filtered and absorbed, and clean air is then released into the atmosphere. This provides a safe working environment for operators and ensures the recycling of grinding metal dust, achieving an environmentally friendly production process.

Advantages of Using This Equipment:

Increased Production Efficiency: Continuous feeding and through-type processing meet the required order volumes.

Improved Product Quality: The consistency of processed workpieces is excellent, and surface treatment quality far exceeds manual processing.

Cost Savings: Processing cost per unit area is significantly lower than manual methods.

Safety and Environmental Protection: Dust absorption ensures safe operation and improves the work environment.

Main Technical Parameters:

| Parameter | Specification |

| Processing Width | ≤ 780mm |

| Processing Thickness | 0.5 ~ 80mm |

| Minimum Processable Size | 50mm × 50mm |

| Total Machine Power | 22KW |

| Sanding Roller Brush Size | Φ300mm × 300mm |

| Conveying Speed | 0.5 ~ 6m/min (adjustable by frequency converter) |

| Roller Brush Rotation Speed | 8 ~ 26m/s (adjustable by frequency converter) |

| Roller Brush Orbital Speed | 1 ~ 15r/min (adjustable by frequency converter) |

| Number of Roller Brush Planetary Orbital Shafts | 1 |

| Number of Roller Brush Planetary Rotational Shafts | 4 |

| Processing Thickness Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Roller Brushes |

| Dust Extraction Airflow | 3000m³/h |

| Machine Dimensions | Length 2350mm × Width 1750mm × Height 2150mm |

| Total Machine Weight | Approximately 1.6 tons |