The electro-hydraulic proportional press brake is a type of press brake machine that integrates an electro-hydraulic proportional control system for more precise control over the bending process. It uses advanced electronic control to adjust hydraulic pressure and flow, allowing for better accuracy, responsiveness, and adaptability compared to traditional mechanical or hydraulic systems.

Key Features of Electro-Hydraulic Proportional Press Brakes:

Proportional Control:

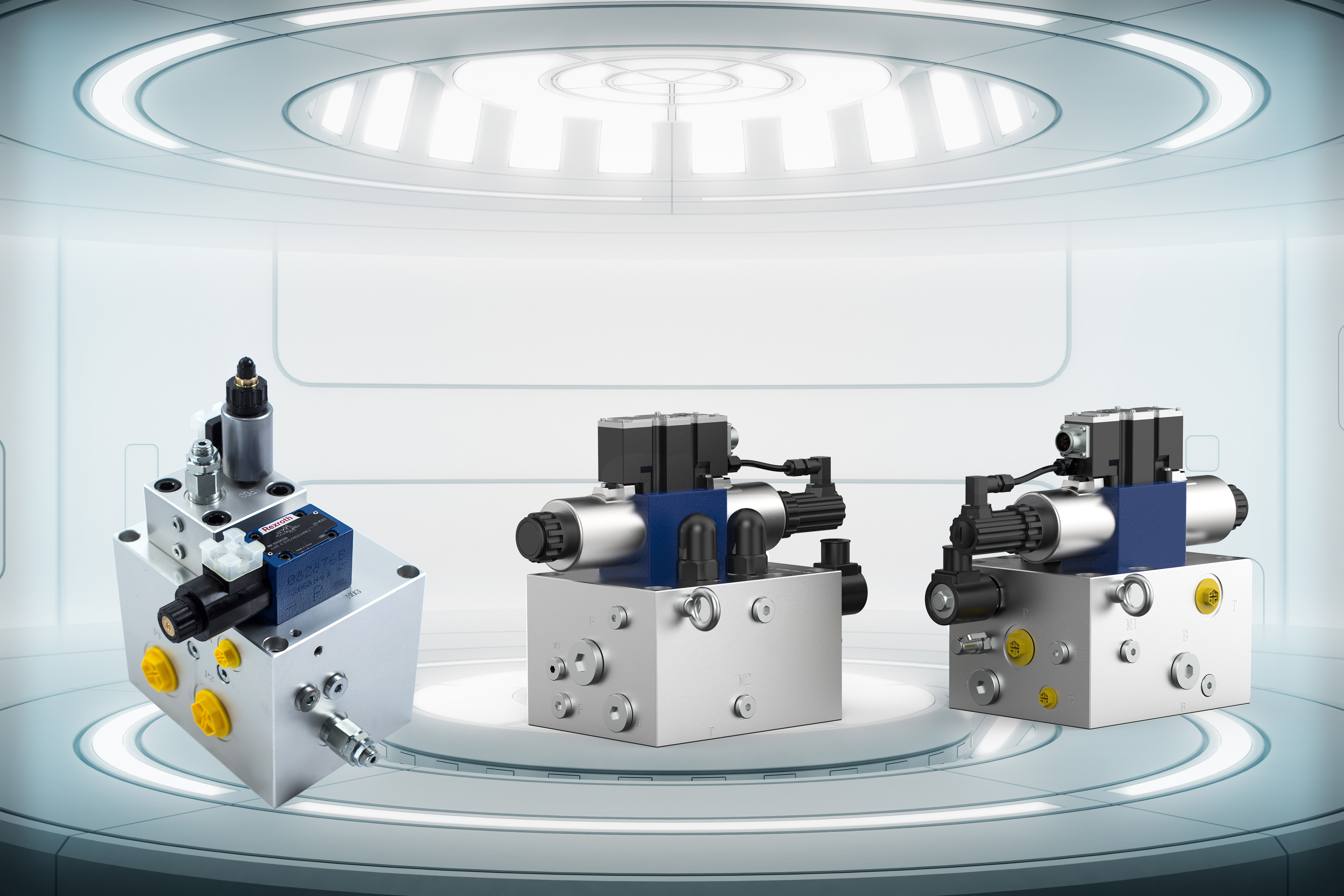

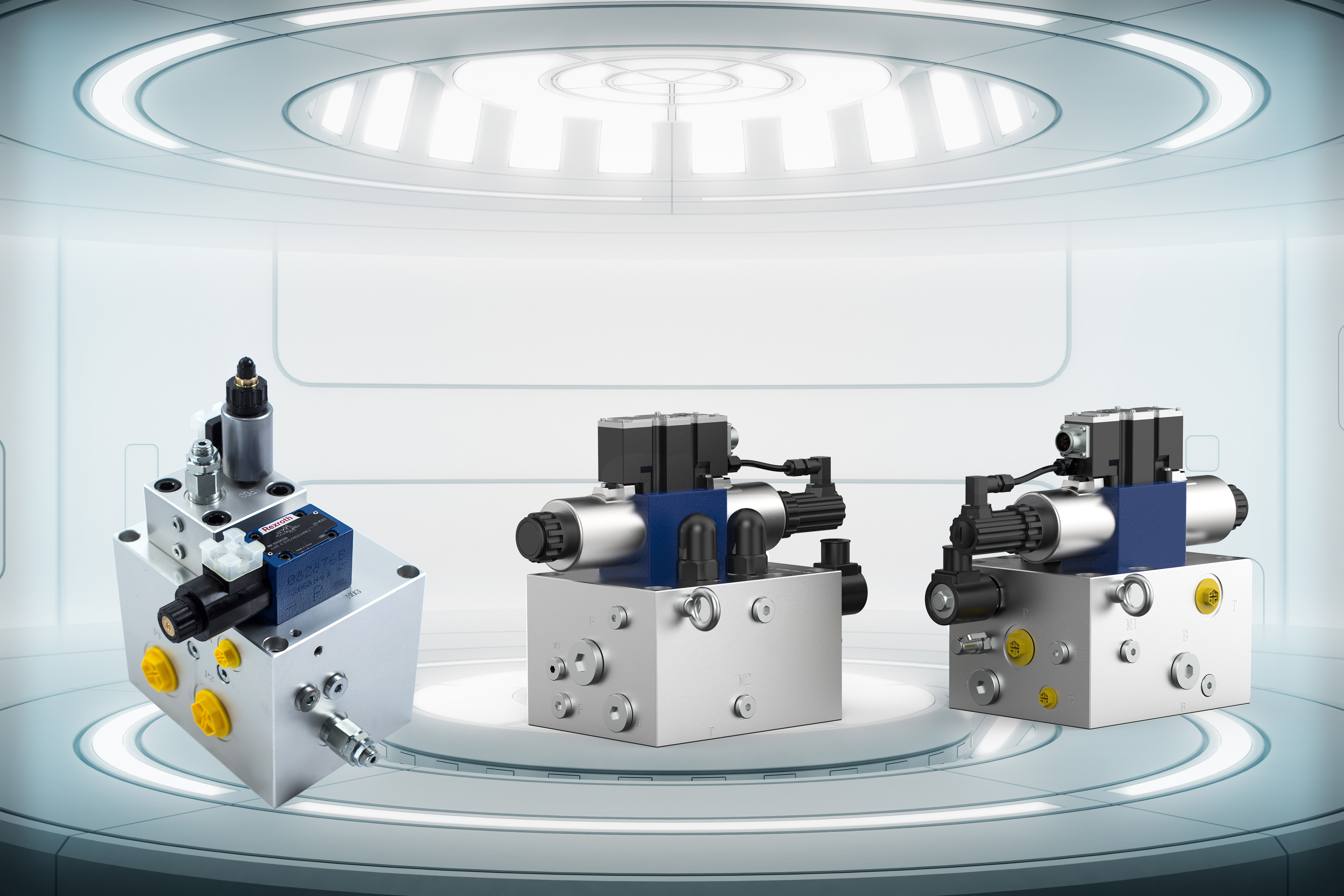

The electro-hydraulic proportional control system uses proportional valves (such as PV50, SVF), which are electronically controlled to regulate fluid flow and pressure. This enables precise control over the bending process and ensures that the machine responds smoothly to adjustments.

Increased Precision:

These systems provide highly accurate control over the machine’s movements, such as ram speed and force application. This is particularly important for applications that require consistent and precise bending angles, such as in the automotive or aerospace industries.

The machine's positioning can be adjusted to within very fine tolerances (e.g., 0.01mm) due to the advanced control system, ensuring high-quality results with minimal human error.

Efficient Energy Usage:

Compared to traditional hydraulic systems, electro-hydraulic proportional press brakes tend to be more energy-efficient. The system only draws power when needed, reducing unnecessary energy consumption and minimizing operating costs.

Faster Response Times:

Integrated Features:

These press brakes often come with integrated hydraulic crowning systems to compensate for any deflection of the press brake’s frame during heavy bending, ensuring uniformity in bending across the entire length of the machine.

The LVDT displacement sensors (Linear Variable Differential Transformers) are commonly used in these machines for feedback control, further enhancing precision and responsiveness.

Customizable Configurations:

The electro-hydraulic proportional system can be tailored to suit specific needs by adjusting the system's settings (e.g., servo valve and pump configurations). It can accommodate a variety of tonnage ratings, from smaller 30T machines to larger ones, such as 500T, 1000T, or even 1200T models, with pumps and valves rated accordingly.

Simplified Maintenance and Longevity:

Advantages of Electro-Hydraulic Proportional Press Brakes:

Accuracy: Achieves high precision in bending, with minimal distortion or variation.

Energy Efficiency: Optimizes energy use, leading to lower operational costs.

Flexibility: Suitable for complex parts and a wide range of material types, including those with varying thicknesses.

Enhanced Productivity: Faster adjustments and better feedback systems enable quicker setup and reduced downtime.

Typical Components of an Electro-Hydraulic Proportional Press Brake:

Hydraulic Pump: Supplies hydraulic fluid to the system, with varying capacities depending on the machine's tonnage.

Proportional Valve: Regulates the flow and pressure of hydraulic fluid to control the motion of the machine.

Servo Valve: Provides precise control over the movement of the ram and other machine components.

Crowning System: Ensures that the machine maintains an even bending force across its length, correcting any deflection in the frame.

LVDT Sensors: Provide real-time feedback on the position of the ram, enabling precise control over bending angles.

Specifications and Configuration Table:

| Model | 400T | 500T-600T | 800T | 1000T | 1200T |

| Crowning Valve (常开) | PV-75 | PV-75 | PV-75 | PV-75 | PV-75 |

| Crowning Valve (常闭) | SVF-50-21C | SVF-63-21C | SVF-80-21C | SVF-100-21C | SVF-125-21C |

| Pump (油泵) | 50cc | 63cc | 64cc + 64cc | 80cc + 80cc | 80cc + 80cc |

| Servo Valve (伺服阀) | NG6 | NG10 | NG10 | NG10 | NG10 |

Understanding Components of The Press Brake

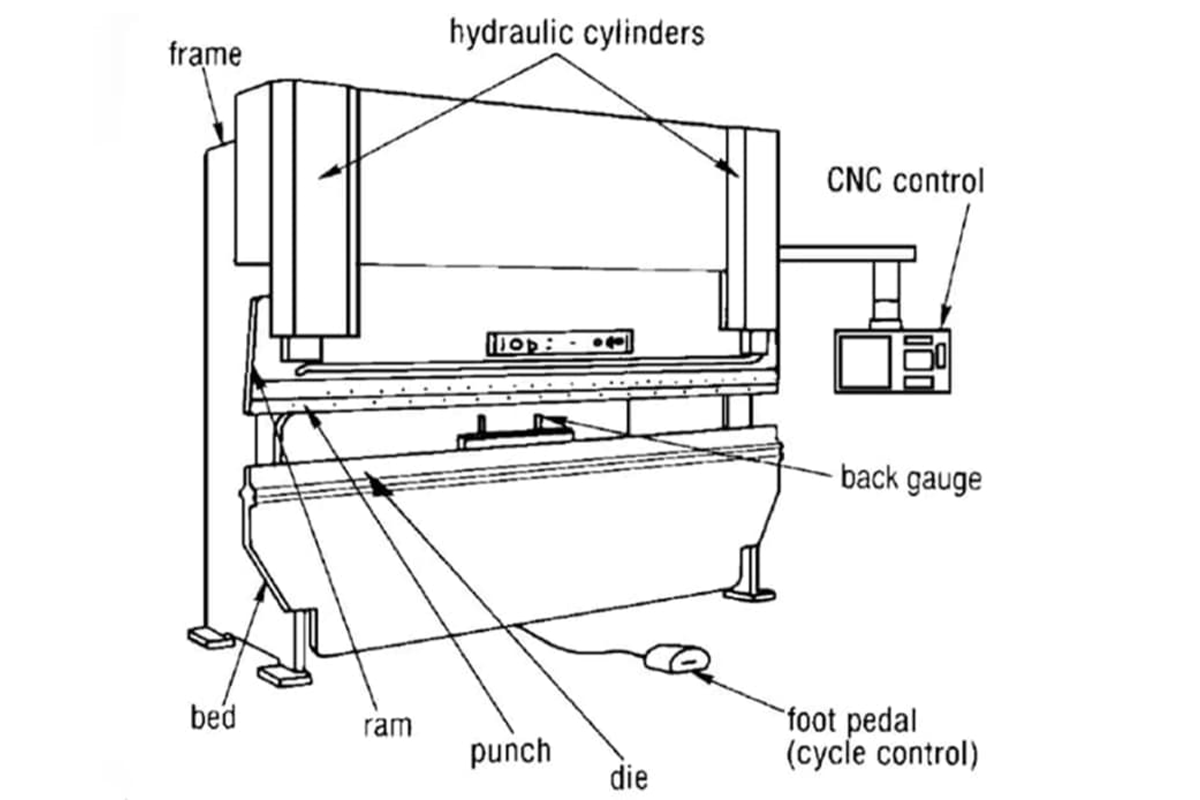

Understanding Components of a Press Brake

A press brake is a machine tool used for bending sheet metal into various shapes. Below is a detailed explanation of its key components and their functions:

1. Frame

The frame forms the structural foundation of the press brake, providing stability and rigidity during operation. It is crucial for consistent bending results and ensures the machine can withstand the high forces involved without distortion.

Types:

C-Shaped Frame: Compact and suitable for smaller, less powerful machines.

Square Frame: Rigid and designed for heavy-duty operations with larger sheets of metal.

2. Bed

The bed is a flat, stationary surface where the workpiece is placed during bending. It ensures proper alignment of the material and supports the bending process.

3. Ram

The ram is a movable upper component that exerts downward force on the workpiece. It is connected to the punch, directly contacting the metal during the bending process.

4. Punch and Die

Punch: A tool with a specific shape mounted on the upper beam to deform the material during bending.

Die: A complementary tool installed on the lower beam, designed to shape the material into the desired form. Together, the punch and die define the final shape of the bent workpiece.

Understanding Components of a Press Brake

A press brake is a machine tool used for bending sheet metal into various shapes. Below is a detailed explanation of its key components and their functions:

1. Frame

The frame forms the structural foundation of the press brake, providing stability and rigidity during operation. It is crucial for consistent bending results and ensures the machine can withstand the high forces involved without distortion.

Types:

C-Shaped Frame: Compact and suitable for smaller, less powerful machines.

Square Frame: Rigid and designed for heavy-duty operations with larger sheets of metal.

2. Bed

The bed is a flat, stationary surface where the workpiece is placed during bending. It ensures proper alignment of the material and supports the bending process.

3. Ram

The ram is a movable upper component that exerts downward force on the workpiece. It is connected to the punch, directly contacting the metal during the bending process.

4. Punch and Die

Punch: A tool with a specific shape mounted on the upper beam to deform the material during bending.

Die: A complementary tool installed on the lower beam, designed to shape the material into the desired form. Together, the punch and die define the final shape of the bent workpiece.

5. Back Gauge

The back gauge is a precision positioning system located at the rear of the press brake.

6. Control Panel

The control panel is the user interface for operating the press brake.

On CNC press brakes, it allows programming of bending angles, material thickness, and complex sequences, improving precision and efficiency.

7. CNC System

The CNC (Computer Numerical Control) system automates press brake movements, including:

This system ensures high precision and simplifies multi-step operations.

8. Upper and Lower Beams

9. Axes

X-Axis: Controls the back gauge's horizontal movement along the press brake length for flange adjustment.

Y-Axis: Controls the vertical movement of the ram or punch for bending operations.

Z-Axis: Adjusts the back gauge's horizontal positioning along the left and right directions.

R-Axis: Controls the back gauge fingers’ vertical movement for complex or multiple bends.

10. Sheet Support Arms

Mounted at the machine's front, these arms support the workpiece during bending, ensuring alignment and reducing operator strain.

11. Housing Brace

A structural component that connects the two driving cylinders on the upper beam, maintaining machine stability.

12. Foot Pedal

Used by the operator to engage the machine's clutch or initiate bending operations.

13. Crank Shaft

In mechanical press brakes, this component transfers the flywheel's energy to the ram, ensuring efficient energy conversion.