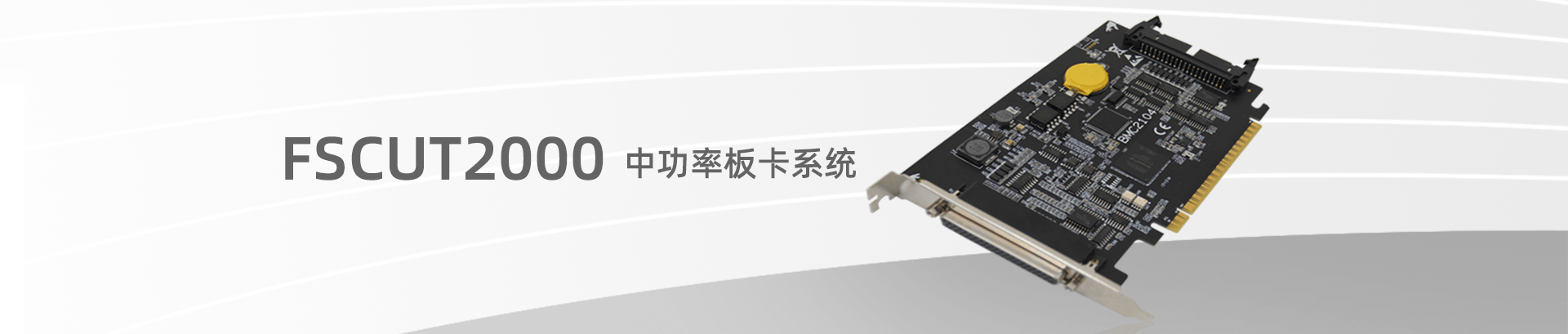

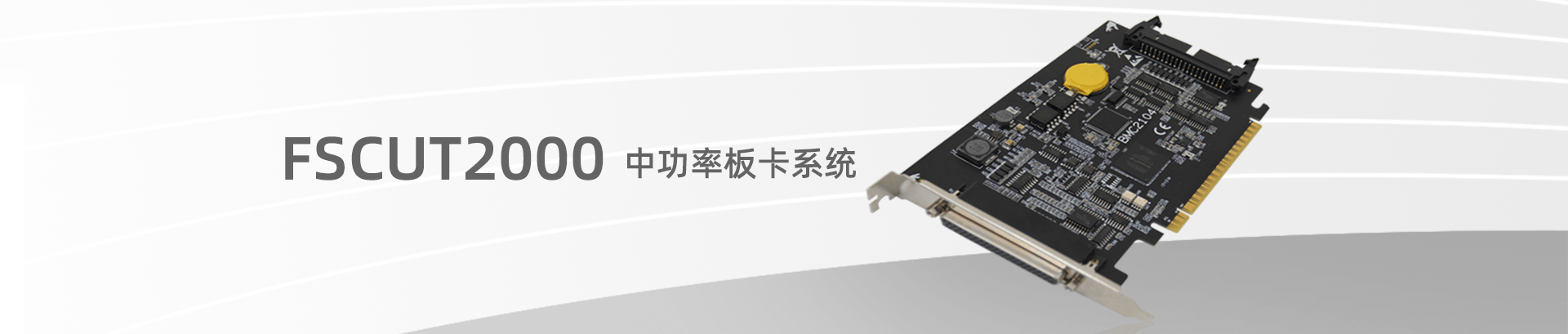

FSCUT2000S Medium Power Laser Cutting Control System

The FSCUT2000S mid-power laser cutting system is a full-featured open-loop control system specially launched for the sheet metal processing industry. Easy to install, easy to debug, excellent performance, complete solutions, it is an upgraded version of FSCUT2000 system.

Specification

Adaptation software

CypCut laser cutting software

control card

BMC2104

Interface Type

PCIe bus, x16 interface, 250MB/s

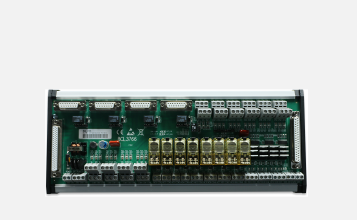

Terminal board

BCL3766

Power requirements

24V DC/2A

Motor control signal

X/Y1/Y2/W axis pulse output, the highest frequency is 3MHz

X/Y1/Y2 axis with encoder input interface, the highest sampling frequency is 10MHz

W axis can control rotating axis or electric focusing module

Dedicated output

2-way DA: 0~10V, 50mA

1 PWM: 5V/24V optional, accuracy 50KHz (0.1%)

Dedicated input

8-way limit: X/Y1/Y2/W axis positive and negative limit

4-way origin: X/Y1/Y2/W axis origin signal

Universal input

15 channels: default low level active, support normally open, normally closed; IN13~IN15 support high and low level switching

Universal output port

8 channels: relay output, load capacity 250V AC/5A, 30V DC/5A

12 channels: thyristor output, load capacity DC 24V/500mA

working environment

Temperature: 0~55℃

Humidity: 5%~95%RH (non-condensing)

Performance characteristics

Craft

Support five levels of perforation, any combination of segmented or progressive

Support communication control of most mainstream lasers on the market

Support basic processes such as flying cutting, leapfrogging, compensation, leading line, micro-connection, pre-perforation, cutting with film, etc.

Support capacitive edge seek, photoelectric edge seek, electric focus, double exchange table, automatic layout, round tube cutting, power-off memory, two-dimensional code, cutting line, maintenance and other advanced functions

Support cooling points, sharp corner ring cutting, release corners and other advanced processes

Support early gas opening and gas flushing

Support starting, closing, and fine cutting processes

Supports air-moving obstacle avoidance, intelligent judgment of leapfrogging

Support simple scheduling, virtual multi-station, scanning code map and other automated applications

control

Open loop control system, Bochu third-generation motion control algorithm

Track accuracy 0.03mm, positioning accuracy 0.001mm, repeat positioning accuracy 0.003mm

Maximum cutting speed 80m/min, maximum moving speed 150m/min

Maximum acceleration 1.5G

Support dual-drive error detection function

Application industry

Suitable for 1500W~6000W medium power fiber laser cutting machine, widely used in sheet metal parts, kitchenware, lamps, cabinets and other industries.

Motion control card

BMC2104

quantity: 1

Wireless handheld box

WKB

quantity: 1

Terminal board

BCL3766

quantity: 1

62 core wire

C62-2/5/10

quantity: 1

37 core wire

C37-2/5/10

quantity: 1

Servo line

C15-1.5/2.5/4

Quantity: 4