FSCUT7000 system ultra-fast laser intelligent bus control system

The FSCUT7000 system is an intelligent bus system designed for precision processing using ultra-fast lasers such as picoseconds and femtoseconds. Fully meet the basic characteristics of high-speed, high-precision, high-precision light control, automatic docking and other basic characteristics: use a new control algorithm with a bus structure to achieve high-precision trajectory processing; use high-real-time hardware slave stations to achieve 0.1um~10um equal spacing light control (PSO) function; through the combination of standard communication protocol and parallel plc, automatic online production is realized.

Specification

Adaptation software

UltraCut precision laser processing system

Adapt to the master station

CypTronic-EP bus master

I/O slave

HPL2720E bus input and output resource expansion card

BCL4516E bus I/O expansion board (optional)

Power requirements

24V DC/5A

PSO function

Support 9 kinds of light control modes, the distance between light points can be set from 0.1μm-10μm

Axis control

Supports up to 32 EtherCAT servo drives for synchronous control

Resource expansion

Support up to 32 EtherCAT input and output slave station expansion

performance

Supports up to 5G acceleration

Precision

Theoretical control accuracy ±1um

working environment

Temperature: 0~60℃

Humidity: 10%~90%RH (no condensation)

Performance characteristics

Function

Support the function of equal spacing light emission control (PSO), and the light emission distance can be set to 0.1-10μm

Nine light emission control modes, which can be adapted to all kinds of ultra-fast lasers

Connect the laser through rs232 and EtherNET to realize the read and write of key parameter status

Supports process functions such as transition line, import and export line, flight cutting, editing of shifting points, and arc automatic deceleration

Support dual y-axis machining application scenarios

Support parallel plc custom editing, with a richer automated process

Match ModbusTCP, ADS or other standard communication protocols to meet the needs of online production

Optional visual positioning module to deal with circle, cross or other general mark point recognition and positioning processing

control

Communication: RTOS real-time kernel is adopted, and the bus control signal cycle defaults to 1ms

Accuracy: The track accuracy is 1μm, and the actual processing effect of ±3μm is comprehensively realized

Support interferometer data compensation and machine verticality compensation

Application industry

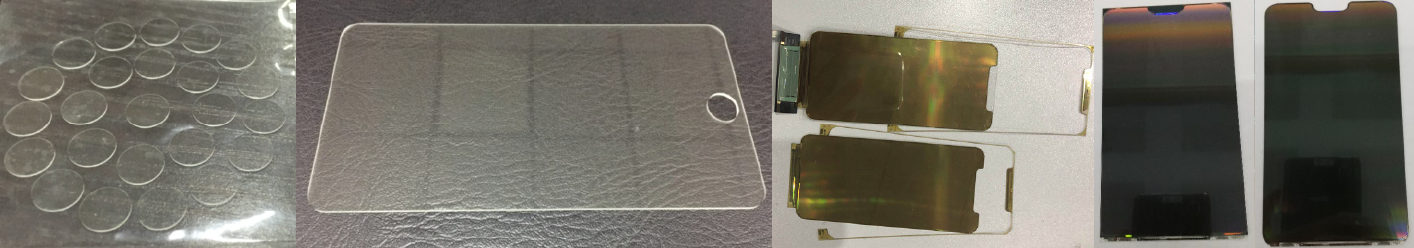

It is suitable for scenes where ultra-fast lasers such as picoseconds and femtoseconds are used for precision processing. It is widely used in precision processing occasions such as glass ceramic brittle and thin materials, display screens, semiconductors, and photovoltaic materials.