FSCUT3000S is a control system developed for pipe processing

FSCUT3000S is a control system developed for tube processing. It supports high-precision and high-efficiency cutting of square tubes, round tubes, racetrack-shaped and elliptical tubes, as well as angle steel and channel steel. It is an upgraded version of FSCUT3000.

Specification

Adaptation software

TubePro tube cutting software/CypCut plane cutting software

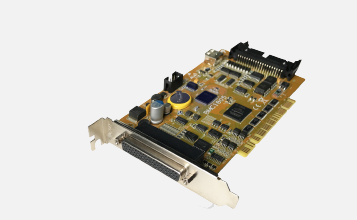

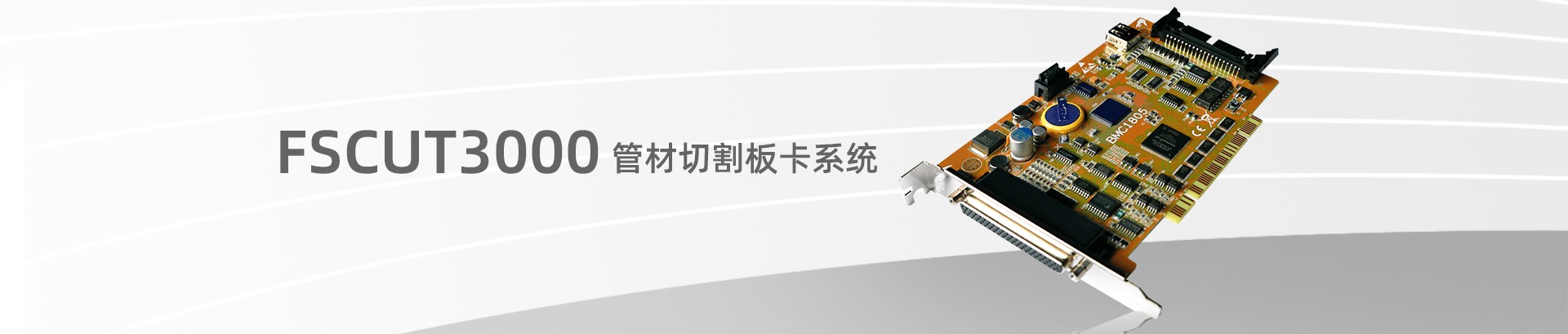

control card

BMC1805

PCI type

32-bit PCI bus, 132MB/s

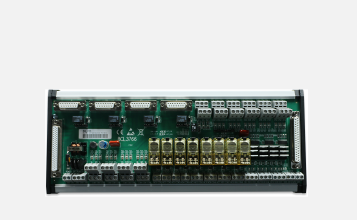

Terminal board

BCL3766

Power requirements

24V DC/2A

Motor control signal

X/Y1/Y2/W axis pulse output, the highest frequency is 3MHz

X/Y1/Y2 axis with encoder input interface, the highest sampling frequency is 10MHz

W axis can control rotating axis or electric focusing module

Dedicated output

2-way DA: 0~10V, 50mA

1 PWM: 5V/24V optional, precision 5KHz (0.1%)

Dedicated input

8 channels: relay output, load capacity 250V AC/5A, 30V DC/5A

12 channels: Thyristor output, load capacity DC 24V/500mA

Universal input

15 channels: 12 channels are active at low level, 3 channels can be changed to be active at high and low levels through jumpers

working environment

Temperature: 0~55℃

Humidity: 5%~95% (no condensation)

Performance characteristics

Craft

Support the real-time deviation compensation of the tube core, reduce the clamping requirements of the tube, and greatly improve the accuracy of the perforation

Support angle steel and channel steel cutting

Support the setting of a separate corner process to improve the quality of pipe corner cutting

Support automatic loading and unloading and cycle processing, support standard automatic feeding action

Compatible with all functions of FSCUT2000 laser cutting system

control

Open-loop control system, using Baichu fifth-generation motion control algorithm

Track accuracy 0.02mm, positioning accuracy 0.001mm, repeat positioning accuracy 0.003mm

Supports real-time feedback of the encoder, adding error measurement tools to facilitate obtaining the best motion parameters of the machine tool

Application industry

It is suitable for special pipe cutting machine or tube-sheet integrated machine. It is widely used in furniture, display racks, construction, sports equipment and other industries.

FSCUT3000