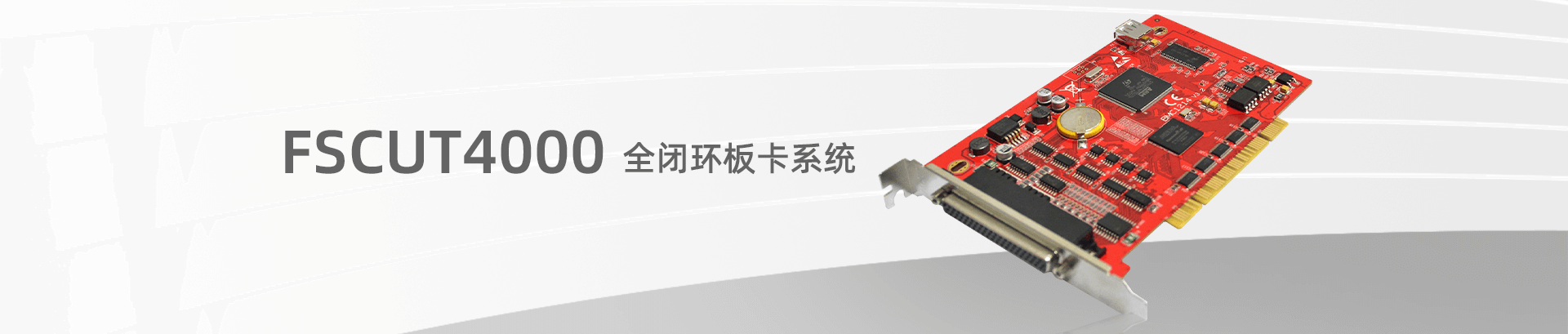

The FSCUT4000 laser cutting system is a high-speed, high-precision full-closed-loop laser control system independently developed and completed earlier in China. Supports advanced functions such as automatic adjustment, cross-coupling control, and smart perforation.

Specification

Adaptation software

CypCut laser cutting software

control card

BMC1214

Interface Type

32-bit PCI bus, 132MB/s

Terminal board

BCL3724

Power requirements

24V DC/2A

Motor control signal

X/Y1/Y2/W axis analog output, -10~+10V

X/Y1/Y2/W axis with encoder input interface, the highest sampling frequency is 10MHz

Dedicated input

4-channel origin: low-level effective, support normally open normally closed

8-channel limit: low-level effective, support normally open and normally closed

Dedicated output

4-way DA: 0~10V, 50mA

1 PWM: 5V/24V optional, accuracy 50KHz (0.1%)

Universal input

12 channels: low-level effective, support normally open, normally closed

IN10/11/12 support jumper change to high level effective

Universal output port

Relay output 6 channels: load capacity: 250V AC/5A, 30V DC/5A

Thyristor output 14 channels: load capacity: 24VDC/500mA

working environment

Temperature: 0~55℃

Humidity: 5%~95% (no condensation)

Performance characteristics

Craft

Any combination of segmented or progressive, fixed height zoom perforation and other intelligent perforation methods

Support pre-perforation, grouped pre-perforation, cooling point, stop light blowing, sharp corner ring cutting and other thick plate processes

Support speed detection, automatic adjustment, capacitor edge seeking, electric focus, workbench exchange, multi-task processing, automatic layout, flying cutting, leapfrogging, QR code, cutting line, maintenance and other advanced function modules

Support simple scheduling, virtual multi-station, scanning code map and other automated applications

Support starting, closing, and fine cutting processes

control

Closed-loop control system, adopts Baichu fourth-generation motion control algorithm

Control accuracy 0.005mm, actual trajectory accuracy 0.01mm, positioning accuracy 0.001mm, repeat positioning accuracy 0.002mm

Maximum cutting speed 80m/min. Maximum moving speed 200m/min

Maximum acceleration 2.5G

All master-slave dual-drive, cross-coupling control of each axis, forward-looking speed and acceleration.

Application industry

Suitable for high-precision laser processing equipment. It is widely used in precision processing occasions such as 3C industry, brittle and thin materials such as glass ceramics, polymer films, and eyewear accessories.