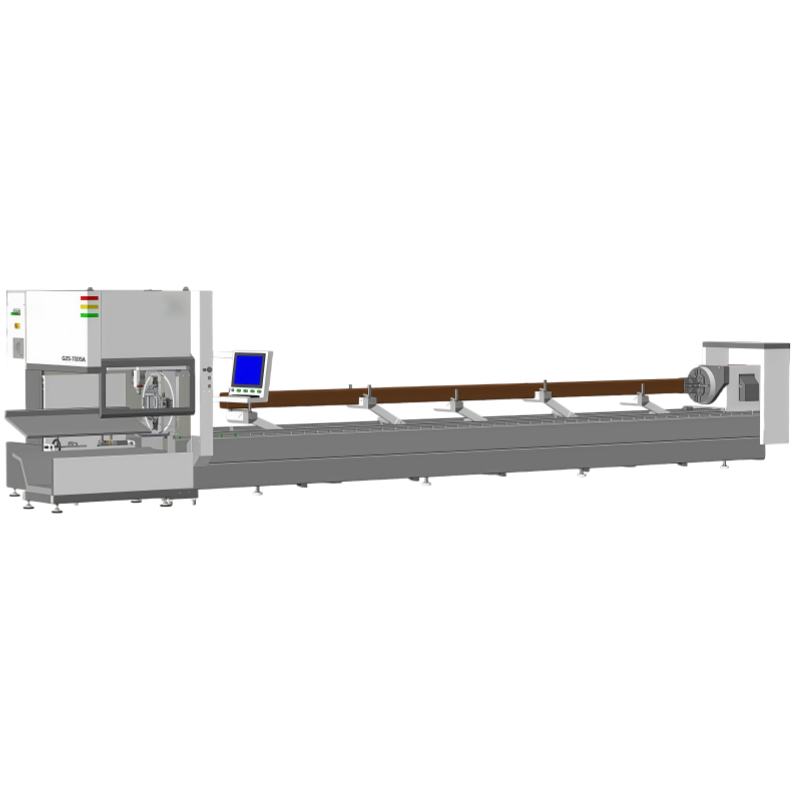

G25-7025B Fiber Laser Tube Cutting Machine (3000W Full Automatic)

The G25-7025B is a full-automatic fiber laser tube cutting machine with a 3000W laser power, designed for high precision and high-speed tube processing. It is especially suitable for industries like steel structures, aerospace, automotive, and more.

Key Specifications and Features

General Features

Model: G25-7025B

Laser Power: 3000W

Platform: Medium-sized platform with 250 chuck, length of 7 meters for tube processing

Automatic Feeding: Full automatic feeding system (modular)

Suitable Tube Types:

Round, Square, Rectangular, Elliptical, I-beams, U-beams, Angle Steel, Special Profiles, and more.

Tube Size:

Industries

Key Components Configuration

| Component | Brand | Model/Origin |

| Fiber Laser | Chuangxin | 3000W (Domestic Leading Brand) |

| Cutting Head | Osprey | 3000W (Domestic Leading Brand) |

| Gear Rack | YYC (Taiwan) | M2-6 Grade |

| Reducer | Xinbao (Japan) | 110-090 |

| Linear Guide | AIRTAC (Taiwan) | CGH35 |

| Motor | Inovance / Yaskawa (Optional) | High-performance motor, max 4000rpm |

| Dust Removal System | Domestic Leading Brand | Fan (Optional) |

| Water Cooling | Hanli | Domestic Leading Brand |

| Electrical Components | Schneider | France, China |

| Pneumatic Components | AIRTAC (Taiwan) | China |

Machine Technical Parameters

Machine Dimensions and Weight

Dimensions: 9600mm (L) x 3200mm (W) x 2800mm (H)

Weight: 8.5 tons

Max Power Consumption: 45-50KW

Operating Temperature: 0-40°C

Cutting Range

Axes Movement

Speed and Acceleration

X/Y Axis Max Acceleration: 1.2G

X Axis Max Speed: 100m/min

Y Axis Max Speed: 120m/min

Loading/Unloading

Cutting Parameters (3000W)

| Material | Thickness (mm) | Cutting Speed (m/min) | Piercing Time (s) | Assist Gas |

| Carbon Steel | 1mm | 7-10/20-25 | 0.1 | Oxygen/Air |

| 2mm | 5-7.5/13-17 | 0.1 |

|

| Stainless Steel | 1mm | 20-25 | 0.1 | Nitrogen/Air |

| 2mm | 12-15 | 0.2 |

|

| Aluminum | 1mm | 20-25 | 0.1 | Nitrogen/Air |

| Brass | 1mm | 22-26 | 0 | Nitrogen |

Note: Cutting speed and quality may vary based on material purity, thickness, and gas type.

Power, Water, and Gas Requirements

Electrical Power

Three-Phase Power Supply: 380V ± 5%, 50Hz

Required Power: Minimum 60KVA transformer

Cabling: Minimum 16mm² wire diameter

Grounding: Effective grounding ≤3Ω

Breaker: Need 3 breaker interfaces for the cutting machine

Cooling Water

Assist Gas

Oxygen: Purity ≥99.6%, Pressure ≥1MPa, Flow ≥1m³/min (for carbon steel)

Nitrogen: Purity ≥99.99%, Pressure ≥2.5MPa, Flow ≥2.5m³/min (for stainless steel)

Air: Pressure ≥1.3MPa, Flow ≥1.8m³/min

Installation Environment

Temperature: 5~30°C (Recommended with AC isolation room for laser)

Humidity: <70%

Foundation: The site must be level, free from strong vibrations, and have adequate strength to support the machine.

System Control

CNC System: Beichu based on a Windows PC system for rapid processing with intuitive operations. Supports multiple cutting functions such as progressive piercing, pre-piercing, automatic edge finding, and automatic sorting.

Servo System: High-performance servo motors and drives from international brands provide stable and reliable operation.