The JG-A650 / A850 single-station high-speed die cutting machines are designed for precision cutting of various materials in a high-speed production environment.

Key Features of the JG-A650 / A850

High-Speed Performance:

Both models are engineered for fast and continuous cutting, optimizing production efficiency and reducing cycle times.

Ideal for high-volume operations where speed and accuracy are essential.

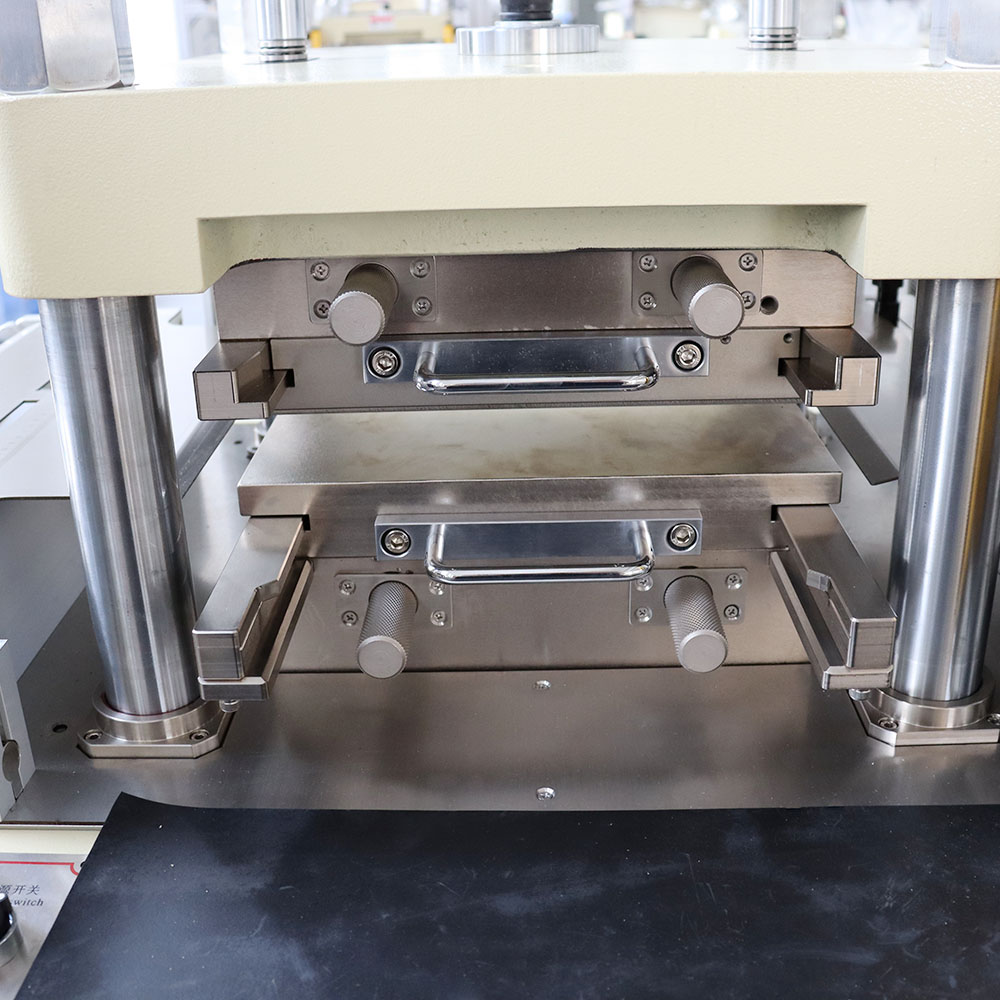

Single-Station Design:

A simplified single-station layout for handling one cutting task at a time.

Focuses on achieving higher precision for each operation, reducing the risk of errors or material waste.

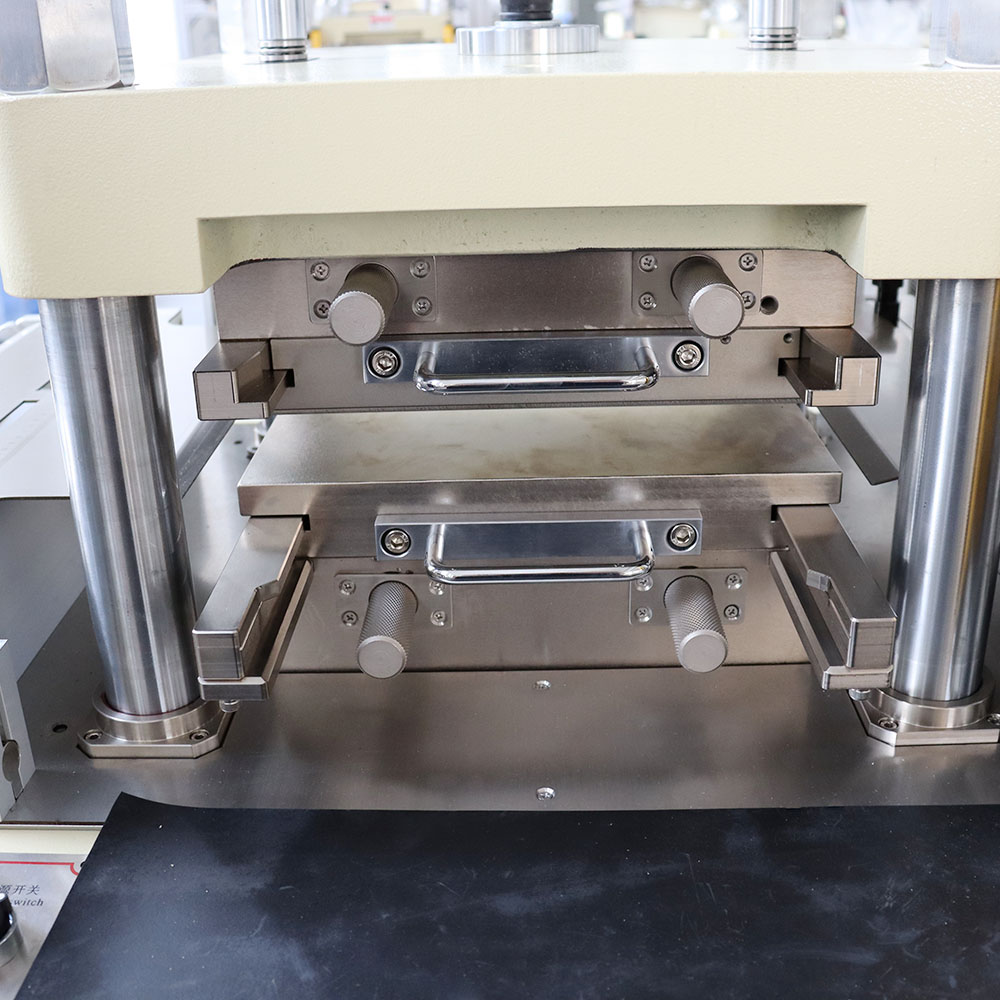

Cutting Area:

JG-A650: Designed with a cutting area of 650mm x 650mm, suitable for medium-sized materials.

JG-A850: Provides a larger cutting area of 850mm x 850mm, making it ideal for larger sheets or applications requiring more material coverage.

Automation and Control:

Integrated with automatic feeding and discharge systems for continuous operation without manual intervention, improving productivity.

Likely features a user-friendly HMI (Human-Machine Interface), allowing operators to control cutting parameters, monitor operations, and make adjustments easily.

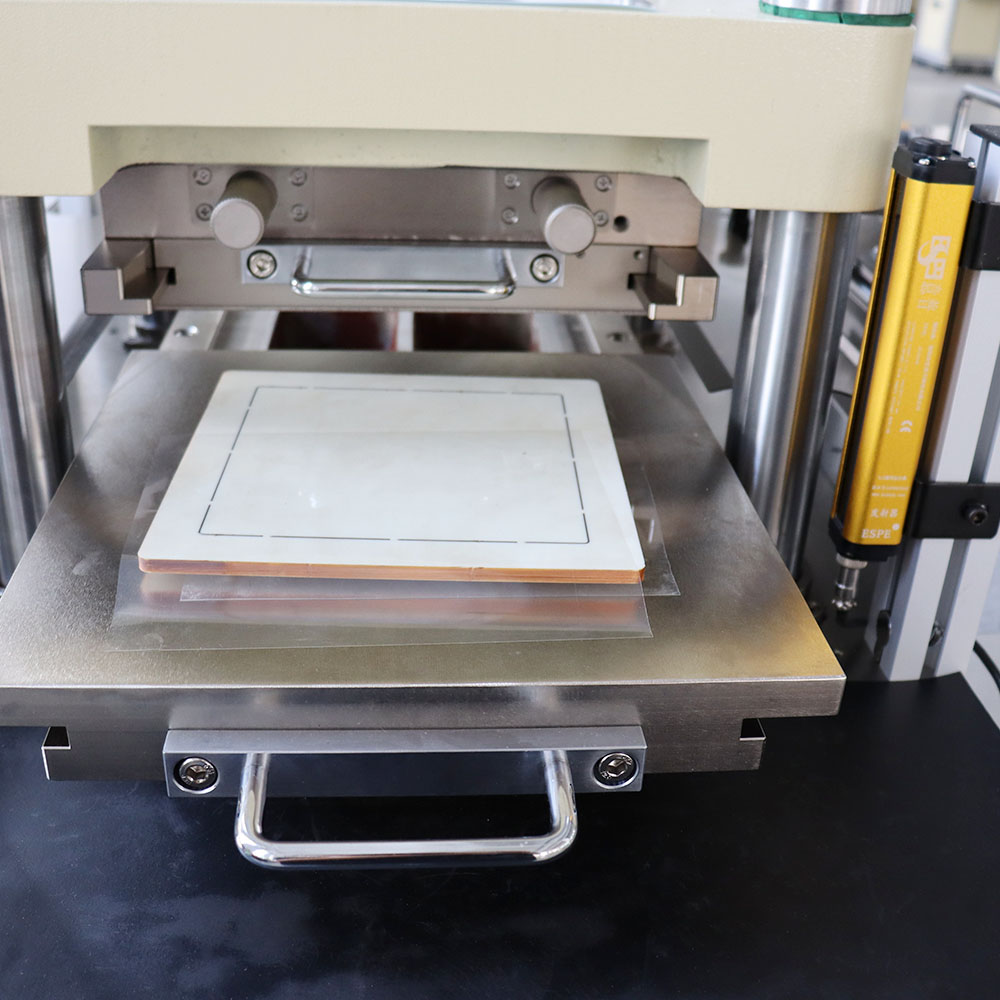

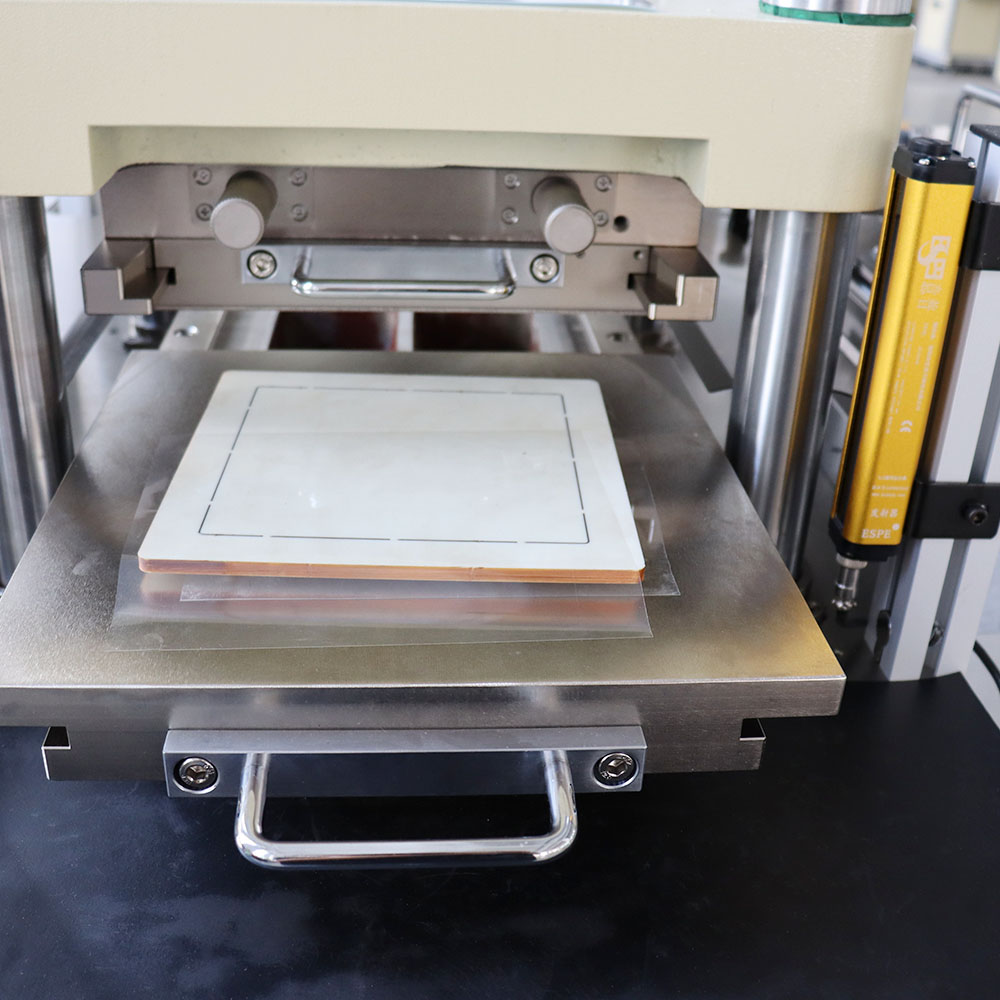

Precision Die Cutting:

High-precision cutting capabilities, suitable for a range of materials such as paper, cardboard, plastic, and even thin metals.

Adjustable cutting pressure to accommodate various material thicknesses, ensuring high-quality results with minimal waste.

Material Versatility:

Paperboard

Plastic Films

Foam Materials

Adhesive Labels

Thin Metal Sheets

Durability and Reliability:

Built with a robust mechanical structure to withstand long-term use in demanding industrial environments.

Features advanced safety mechanisms, including emergency stop buttons and protective covers, ensuring operator safety during high-speed operation.

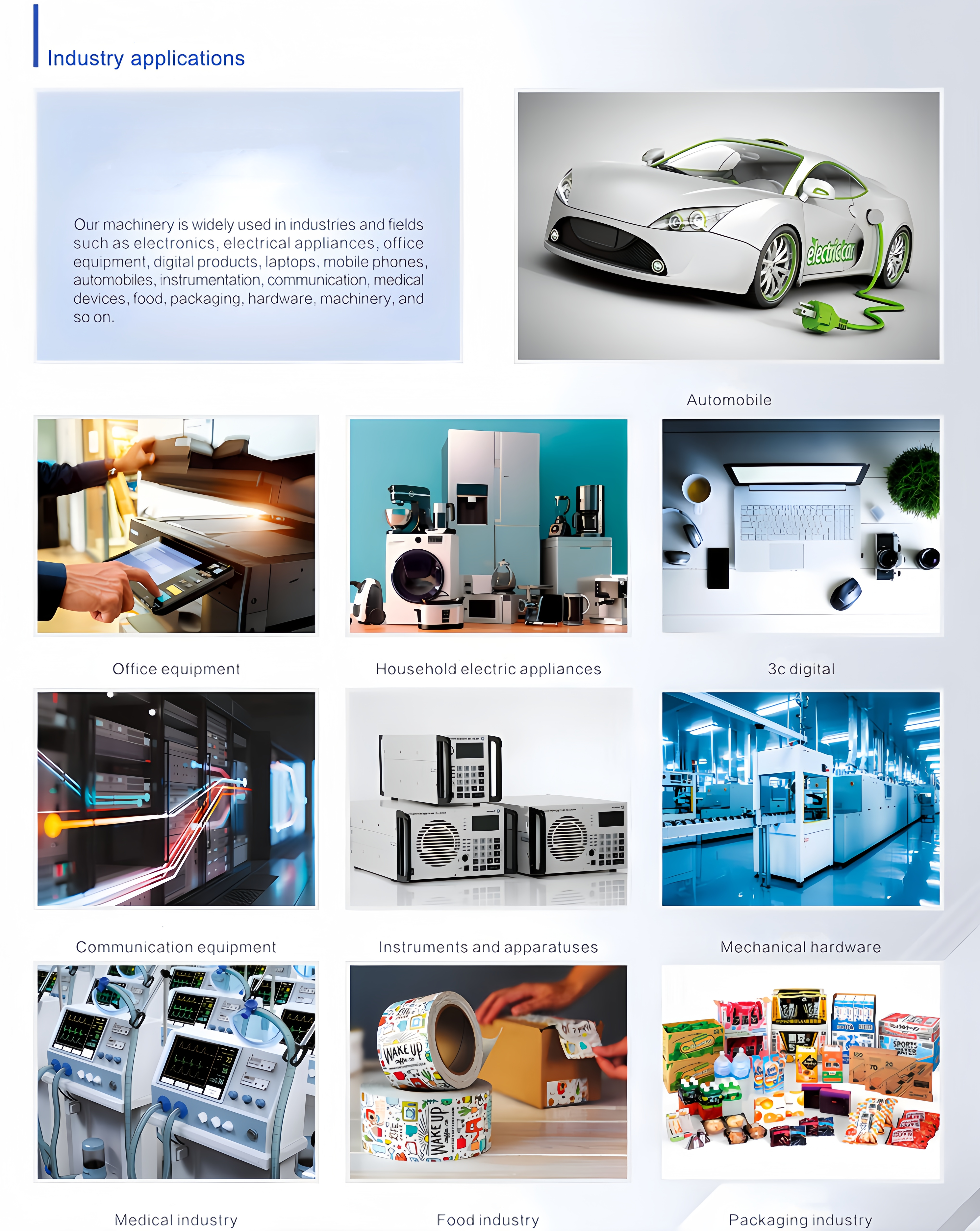

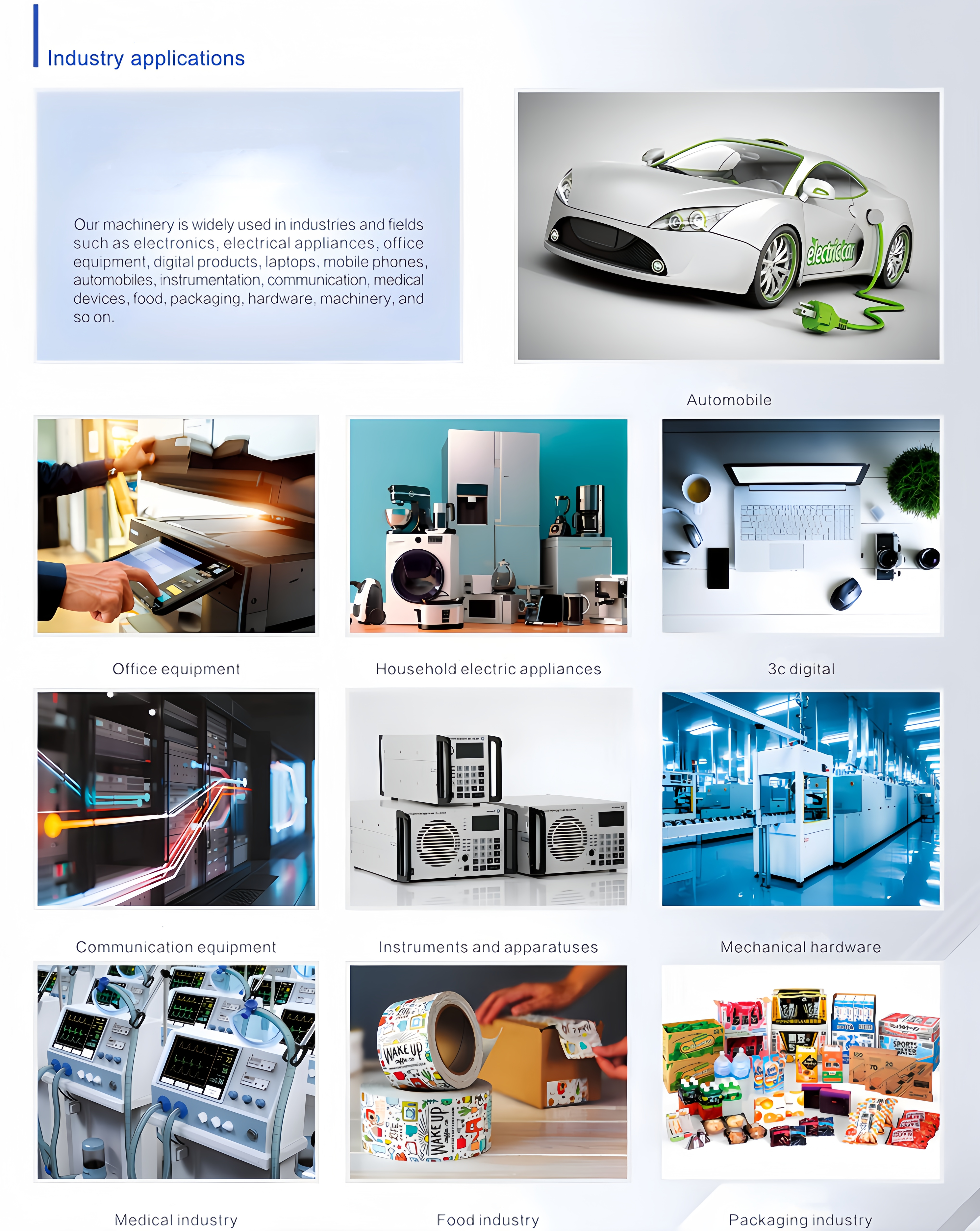

Applications

Packaging Industry:

Label Production:

Automotive Components:

Can be used to produce small, detailed automotive parts like gaskets, seals, and insulating materials from various sheet-based materials.

Printing and Paper Processing:

Electronics:

The machines can handle materials used in the electronics industry, such as insulation films, gaskets, and conductive materials.

Differences between JG-A650 and JG-A850

Cutting Size:

The JG-A650 is designed for smaller to medium-sized materials with a maximum cutting area of 650mm x 650mm.

The JG-A850 provides a larger cutting space of 850mm x 850mm, making it more suitable for larger materials or sheets.

Material Handling:

Benefits

Increased Productivity: The high-speed capabilities allow for faster processing times, increasing throughput in industrial settings.

Consistent Quality: Both machines ensure precise, consistent cuts, improving product quality and reducing material waste.

Flexible Operation: With the ability to process a wide range of materials, these machines are adaptable to various industries.

Maintenance and Care

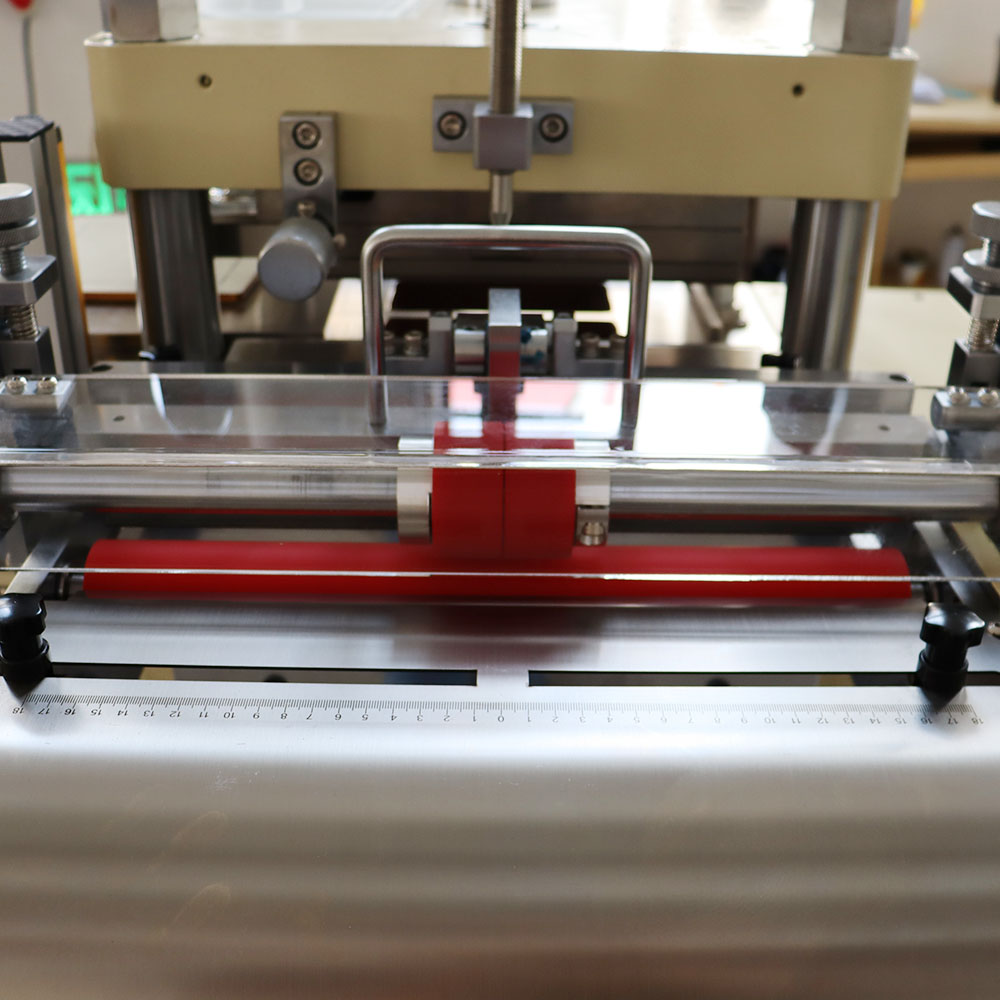

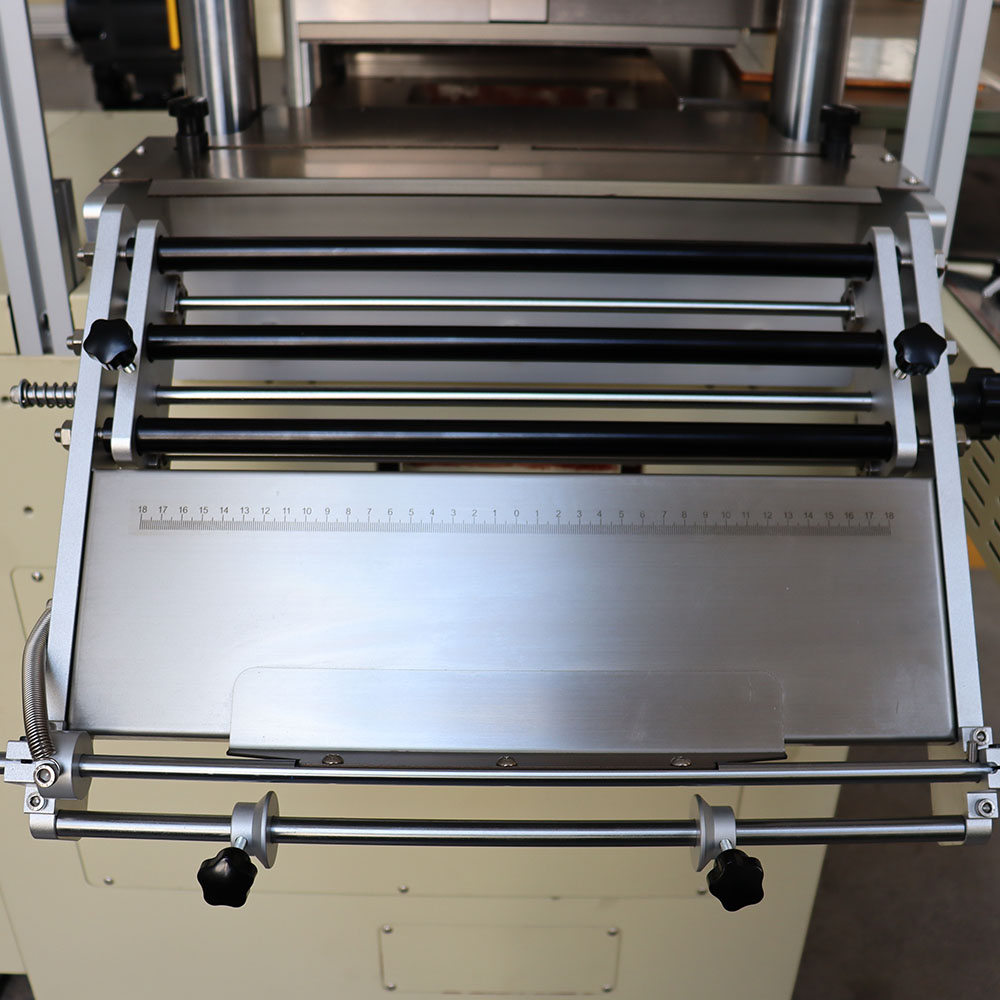

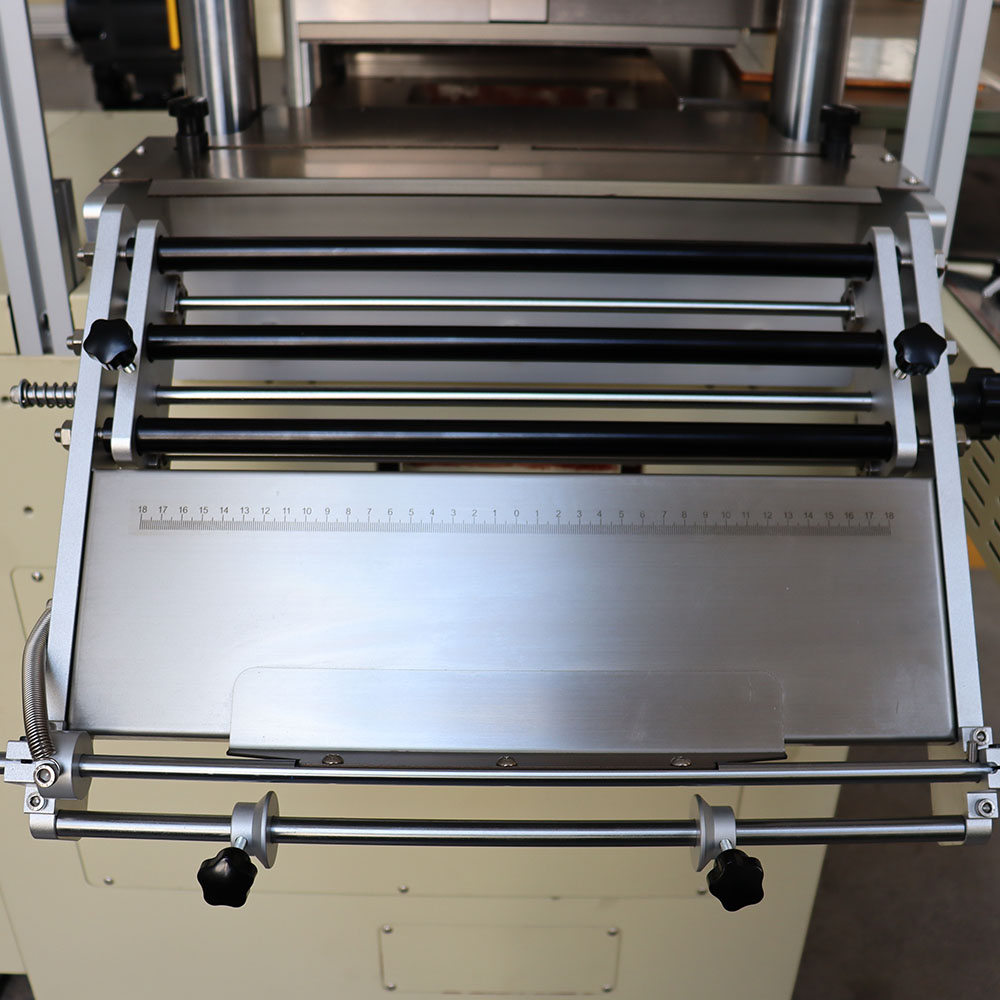

Routine Maintenance: Regular checks on the cutting blades, rollers, and feed systems will help maintain performance and extend the machine’s lifespan.

Lubrication: Ensure that moving parts are properly lubricated to prevent wear and maintain smooth operation.

Calibration: Periodically calibrate the machine to ensure cutting accuracy, especially when switching between different materials.

Technical Specifications:

| Specifications | JT-A650 | JT-A850 |

| Feed Width | 650 mm | 850 mm |

| Max. Die Cutting Area | 630 × 630 mm | 850 × 850 mm |

| Max. Operating Speed | 6000 punches/hour | 6000 punches/hour |

| Punching Stroke | 28 mm | 20 mm |

| Pressure Regulation | 10 mm | 10 mm |

| Voltage Regulation Accuracy | 0.005 mm | 0.005 mm |

| Drawing Accuracy | ±0.05 mm | ±0.05 mm |

| Upper Form Size | 650 × 650 × 20 mm | 860 × 860 × 18.5 mm |

| Lower Template Size | 650 × 650 × 40 mm | 860 × 860 × 18.5 mm |

| Overall Dimensions | 2390 × 1800 × 1900 mm | 2700 × 1850 × 1900 mm |

| Machine Weight | 4200 kg | 5500 kg |

| Air Source Specification | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Total Power | 11 kW | 18 kW |

| Lubrication Mode | Intermittent fuel supply | Intermittent fuel supply |

| Applicable Die Types | Plywood mold, wood mold | Plywood mold, wood mold |

Performance Characteristics:

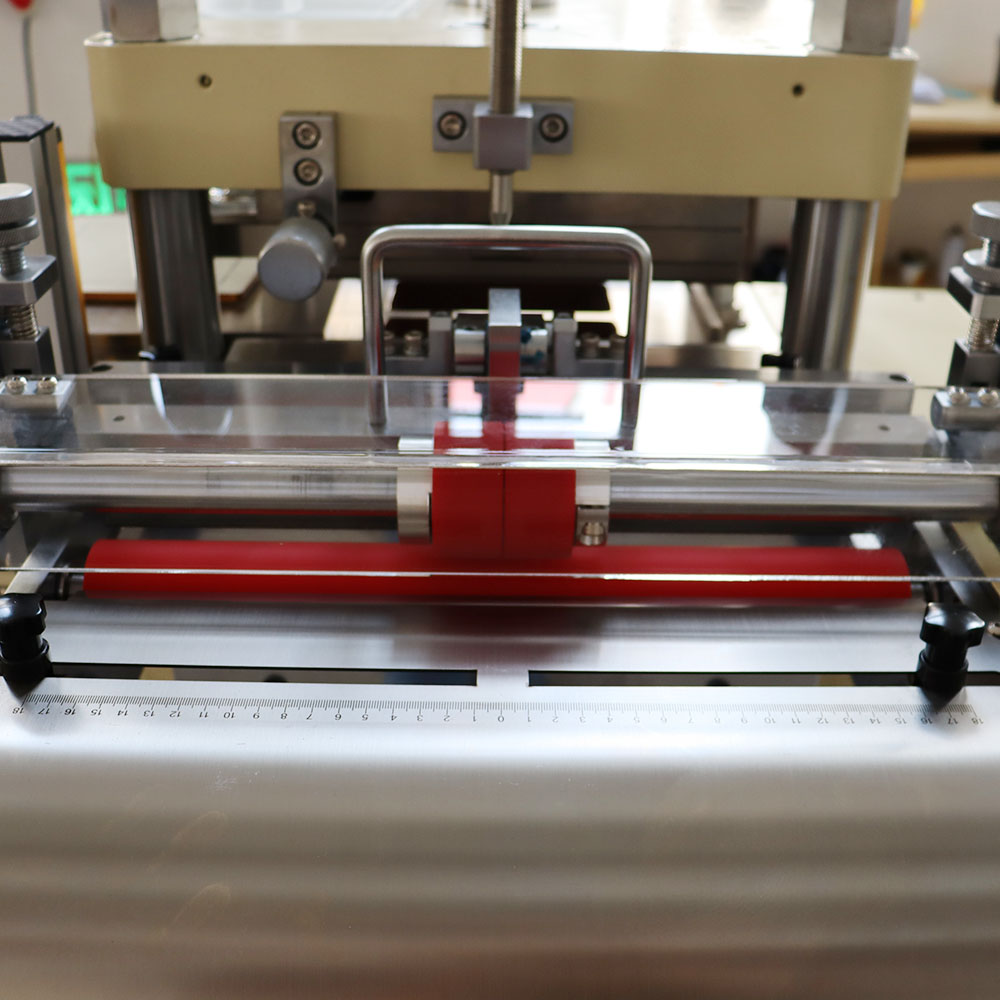

Small hole positioning instant correction device.

Double servo drive for stable pressure, low noise, and precise drawing.

Electric digital display for quick and convenient voltage adjustment.

High punching force with stable die-cutting pressure.

QDC mold allows multiple high precision nesting die cutting to be achievable.

Applications:

This machine is well-suited for industries that require precision die cutting for materials like plywood, wood, and other specialized molds. It is particularly useful in:

The JT-D650/D850 ensures high production efficiency, accurate results, and versatility for a wide range of die-cutting needs.