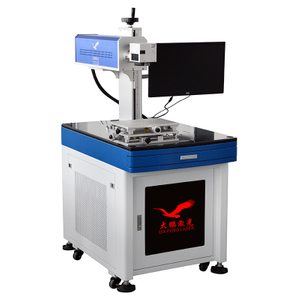

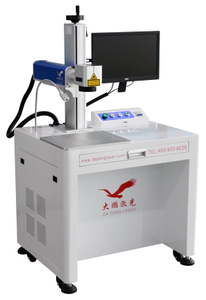

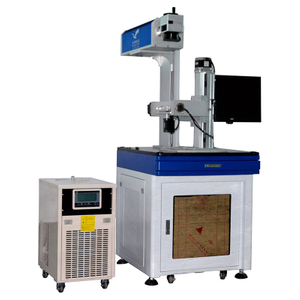

How to engrave letters or patterns on glass--UV laser marking machine

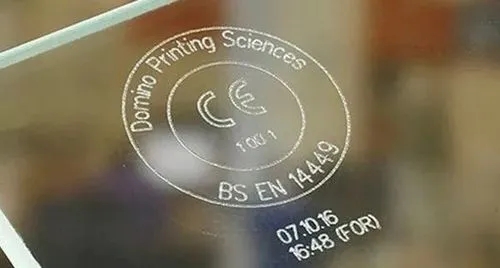

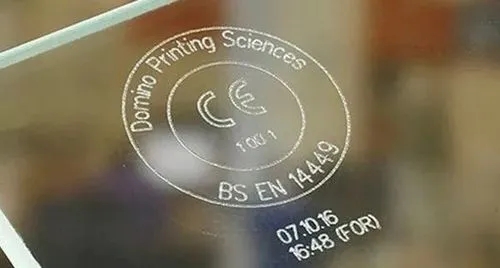

From clear to amber to green and other quality-enhancing colors, glass bottles for beverages and beverages continue to evolve. New beverage glass requirements and packaging lines can determine your marking technology choice, but code quality and content requirements are also factors to consider when choosing. UV laser markers provide clear, long-lasting lettering on virtually any color or type of glass bottle.

Ultraviolet laser marking machine has unique and superior performance, which is very suitable for laser marking of glass bottles. Provides greater quality with greater efficiency, clear, durable coding on virtually any color or type of glass bottle, and is designed for high-quality marking with virtually no font, coding or graphic restrictions.

No chemical treatment, consumables, and chemical pollution are avoided. Laser marking is gathered on the surface of the engraved packaging material with a very high energy density. Environmental labeling technology.

Traditional ink marking needs to store a lot of chemical consumables, ink, solvent, cleaning agent. There is a danger of the ink penetrating the product, and the production date can easily be modified. The UV laser marking machine will produce fine smoke when marking, which can be completely cleaned by the smoke purification device without any harmful chemicals.

Traditional ink marking requires a mixture of ink and solvent. Solvents are highly volatile substances that produce more chemically toxic residues. It will pollute the product, cause secondary pollution to the production environment, and damage the health of workers. It is a product that is gradually eliminated internationally. Now developed countries are increasingly encouraging the use of UV laser marking machines to replace traditional ink markings.

The matrix of traditional ink marking ink is methyl ethyl ketone and acetone, which have high volatile substances, which will produce more chemical residues and toxic gases, which endanger the health of operators. Cleaning of the printer will increase the emission index. The UV laser marking machine will produce fine smoke when engraving, which can be completely cleaned by the smoke purification device without any harmful chemicals.

UV laser marking machine engraving has no consumables cost and labor cost, no consumables management, and reduces the production labor cost and labor pressure caused by purchasing, warehousing, and frequent replacement of consumables.

UV laser markers are a non-contact engraving method that outperforms other technologies in terms of mark quality, durability and consumable volume. Whether it can achieve exquisite product identification depends entirely on the selection process of the parameters of the laser coder. With a clear understanding of the material, application and desired marking, UV laser markers can print high-quality markings on a variety of materials.