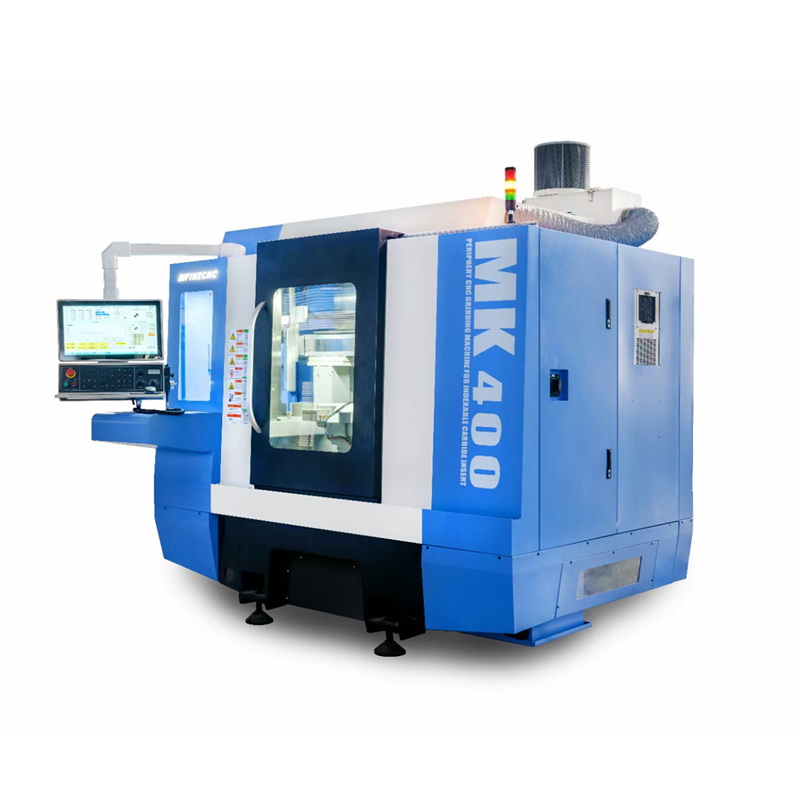

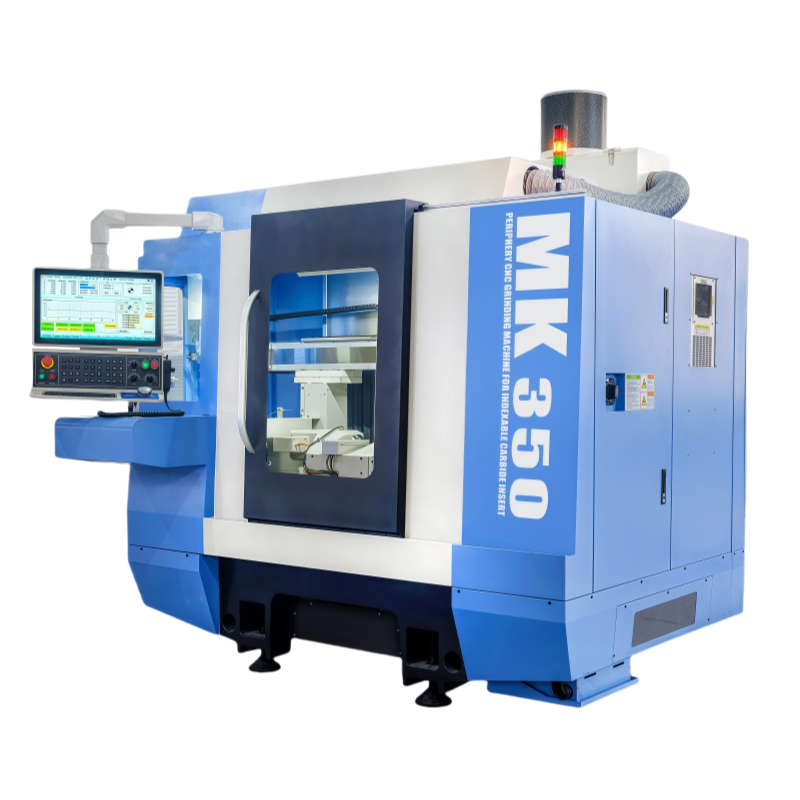

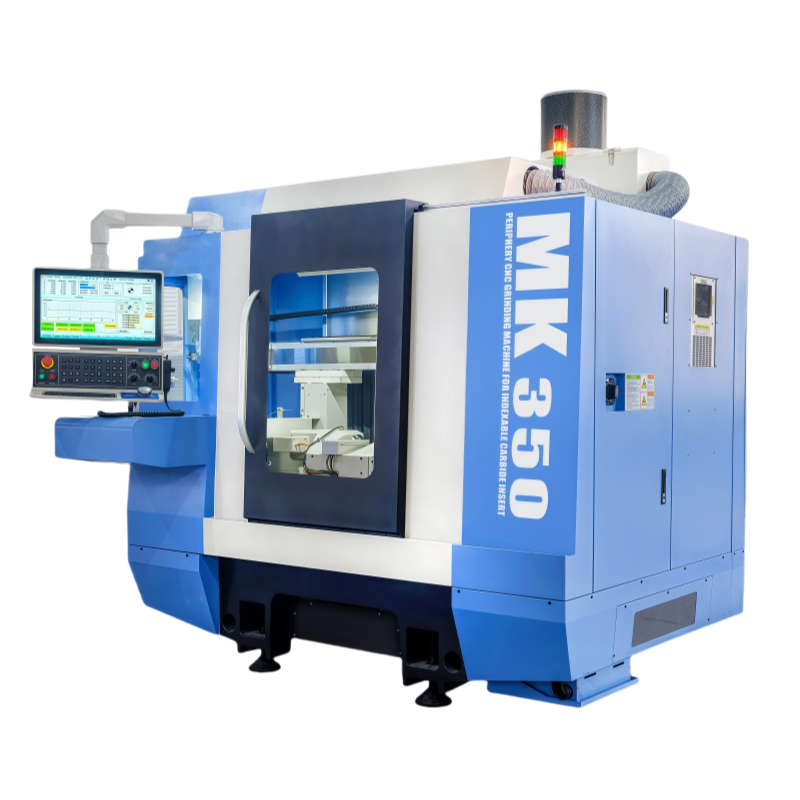

MK-350 Fully Automatic Insert Peripheral Grinding Machine

Advanced 5-Axis CNC Grinder for Precision Insert Periphery Machining

Introduction

The MK-350 represents a pinnacle of innovation in the field of fully automatic insert peripheral grinding technology. Designed with a rigid structural frame and advanced 5-axis CNC control, this machine offers comprehensive solutions for the precise grinding of standard-series indexable inserts, as well as complex dual-side chamfering operations. It is ideally suited for the demands of modern tool manufacturing, where precision, automation, and flexibility are paramount.

Crafted to accommodate a wide range of materials—including carbide, cermet, ceramic, cubic boron nitride (CBN), and polycrystalline diamond (PCD)—the MK-350 supports the production of cutting tools that meet rigorous industry standards for accuracy and durability.

Core Applications and Usage

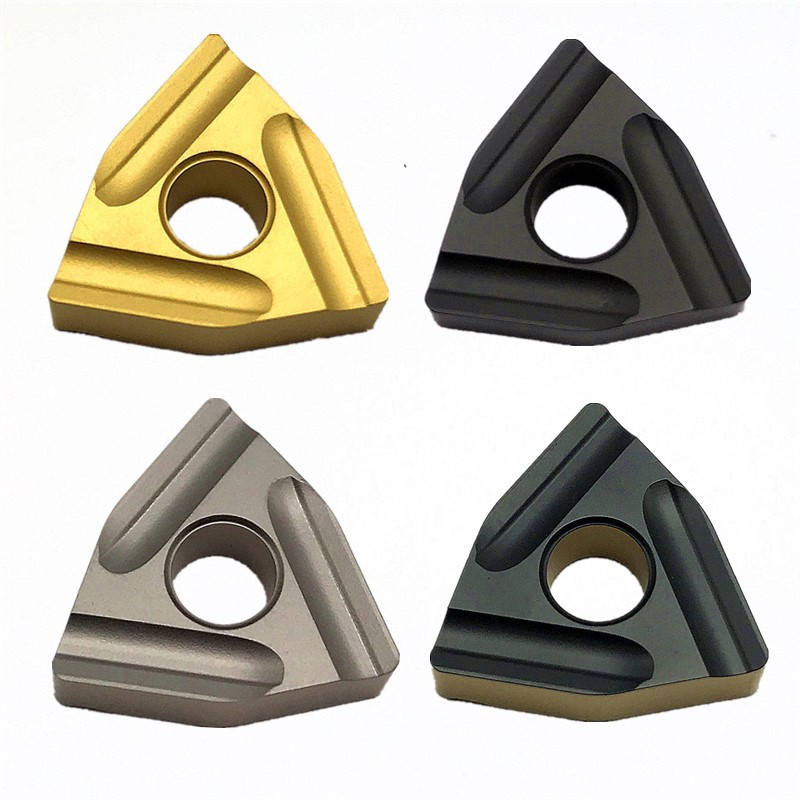

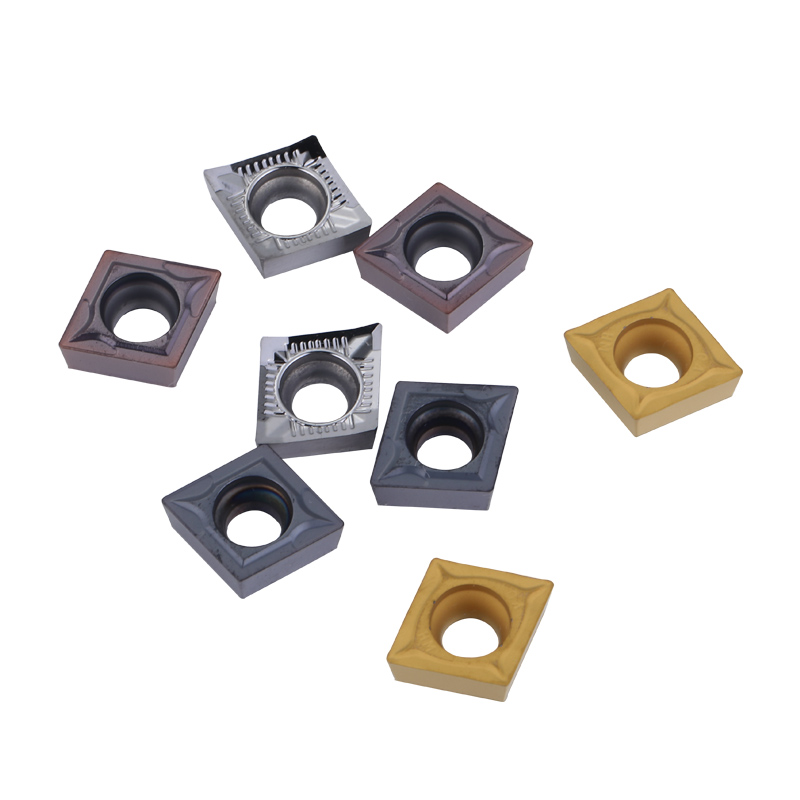

The MK-350 specializes in the fully automatic peripheral grinding and dual-side land chamfering of indexable inserts. This includes the ability to:

Grind the outer periphery of standard indexable inserts with high precision.

Simultaneously create dual-side lands (double chamfers) in a single automated process.

Machine a variety of insert geometries, ranging from standard shapes to more intricate profiles.

Provide consistent surface finish and dimensional accuracy to enhance tool life and performance.

Thanks to its fully automated operation, the MK-350 drastically reduces manual intervention, resulting in increased throughput, higher production efficiency, and improved quality control.

Materials Supported

The MK-350’s versatile design enables it to process inserts made from the following materials:

Carbide: The industry-standard material for metal cutting tools, combining hardness and toughness.

Cermet: Ceramic-metal composites offering wear resistance and improved finish on steel.

Ceramic: High-temperature resistant materials ideal for cast iron and heat-resistant alloys.

CBN (Cubic Boron Nitride): Extremely hard material suited for hardened steel and dry machining.

PCD (Polycrystalline Diamond): The hardest known material, used for non-ferrous and abrasive materials.

This wide compatibility allows manufacturers to utilize one machine platform across diverse tooling requirements.

Mechanical and Control Architecture

Rigid Structural Design

The MK-350 features a robust frame and gantry structure engineered to minimize vibration and thermal deformation during operation. This foundation supports high-precision grinding while maintaining stable machining conditions, crucial for ultra-fine insert geometries.

5-Axis CNC Control System

The machine employs a 5-axis simultaneous CNC control system, encompassing:

X-Axis: Left-right oscillation for precise grinding width adjustment.

Y-Axis: Controlled feed axis with direct-drive technology.

A-Axis: Workpiece rotation axis allowing for complete peripheral access.

C-Axis: Workpiece table angular adjustment, ranging from -90° to +90°, enabling versatile chamfer and contour grinding.

V-Axis: Online grinding wheel cleaning to maintain consistent wheel sharpness and performance.

This multi-axis arrangement facilitates complex 3D machining and chamfering in a single setup, eliminating secondary operations and ensuring excellent dimensional repeatability.

High-Power Spindle and Dressing System

The grinding spindle is powered by a 7.5 kW 3-phase induction motor, providing stable and consistent torque for demanding grinding tasks. Complementing this, a 1.5 kW electric spindle powers the dressing device, which performs real-time grinding wheel shaping and conditioning to guarantee optimal surface finish and accuracy.

Automation and Material Handling

Integrated Robotic Handling

To achieve full automation, the MK-350 integrates a 3-axis robotic arm system that manages:

Loading and unloading of inserts.

Tray transportation and positioning.

Precise placement and retrieval of workpieces during the grinding cycle.

The robotic system handles multiple tray types:

Standard trays (350 mm × 350 mm), accommodating standard insert batches.

T-type trays (190 mm × 370 mm), suitable for specialized or smaller production runs.

This automated material handling minimizes downtime and maximizes productivity.

Inspection and Quality Control

The MK-350 is equipped with an advanced online inspection system that measures critical dimensions before and after grinding, including:

Blank material verification to ensure correct insert size and shape.

Post-grinding dimensional accuracy checks for inscribed circles and chamfer quality.

Automated rejection of defective parts, along with regrinding commands or corrections for subsequent pieces.

This closed-loop quality control enhances production yield and guarantees compliance with strict quality standards.

Software and Programming

The machine’s CNC system is designed for ease of use and flexibility:

Dialog-based programming interface simplifies the setup of insert geometries and machining parameters.

Support for a variety of standard insert profiles and the ability to program custom shapes.

Automatic path generation and optimized grinding sequences to reduce cycle time.

Real-time feedback and adaptive control allow dynamic adjustment for tool wear and thermal effects.

Technical Specifications

| Specification | Detail |

| Processing Object | Standard indexable insert periphery grinding and dual-side chamfering |

| Materials | Carbide, Cermet, Ceramic, CBN, PCD |

| Minimum Inscribed Circle | Equilateral Triangle: 3.5 mm; Other Shapes: 4.7 mm |

| Maximum Circumscribed Circle | 45 mm |

| Maximum Workpiece Thickness | 15 mm (can process up to 3 pieces of 4.76 mm simultaneously) |

| Grinding Wheel Diameter | 350 mm |

| Spindle Motor Power | 7.5 kW flange-type 3-phase induction motor (V3 vibration level) |

| Wheel Dressing Motor | 1.5 kW electric spindle |

| CNC Axes Controlled | X, Y, A, C, V, W (core positioning) |

| Maximum Simultaneous Axes | 9 axes |

| Power Supply | 25 kVA / AC 380V / 50-60 Hz |

| Compressed Air Requirements | ≥ 0.5 MPa, 250 N/min |

| Hydraulic Pressure | Maximum 7 MPa |

| Machine Dimensions (WxDxH) | 2,475 mm × 2,250 mm × 2,160 mm |

| Machine Weight | 5,500 kg |

Benefits of the MK-350

Full automation reduces labor costs and increases production throughput.

High-precision multi-axis control enables complex shapes and dual chamfering in one cycle.

Material versatility supports a wide range of insert types and materials.

Integrated quality control ensures consistent high-quality output.

Robust construction guarantees stability and reliability for heavy-duty manufacturing.

Easy programming and rapid changeover facilitate flexible production schedules.

Industry Applications

The MK-350 is an ideal grinding solution for:

Cutting tool manufacturers producing high-precision carbide, ceramic, and CBN inserts.

Automotive and aerospace industries, where specialized inserts with complex profiles are required.

Tool resharpening centers that demand reliable automated reconditioning processes.

Mold and die makers needing precise edge and chamfer finishes.

General machining industry requiring durable and accurately ground cutting tools.

Conclusion

With its combination of rigid mechanical design, advanced 5-axis CNC control, and automated robotic handling, the MK-350 Fully Automatic Insert Peripheral Grinding Machine is engineered to meet the most demanding needs of today’s cutting tool industry.

It delivers unmatched flexibility and precision for grinding standard and complex insert profiles, supporting a broad spectrum of materials from carbide to polycrystalline diamond. The MK-350 not only maximizes production efficiency but also ensures the highest quality and consistency, helping tool manufacturers maintain a competitive edge in a fast-evolving marketplace.

For tool producers seeking a comprehensive, fully automated grinding solution that adapts to diverse insert types and volumes, the MK-350 offers the perfect balance of performance, reliability, and advanced technology.

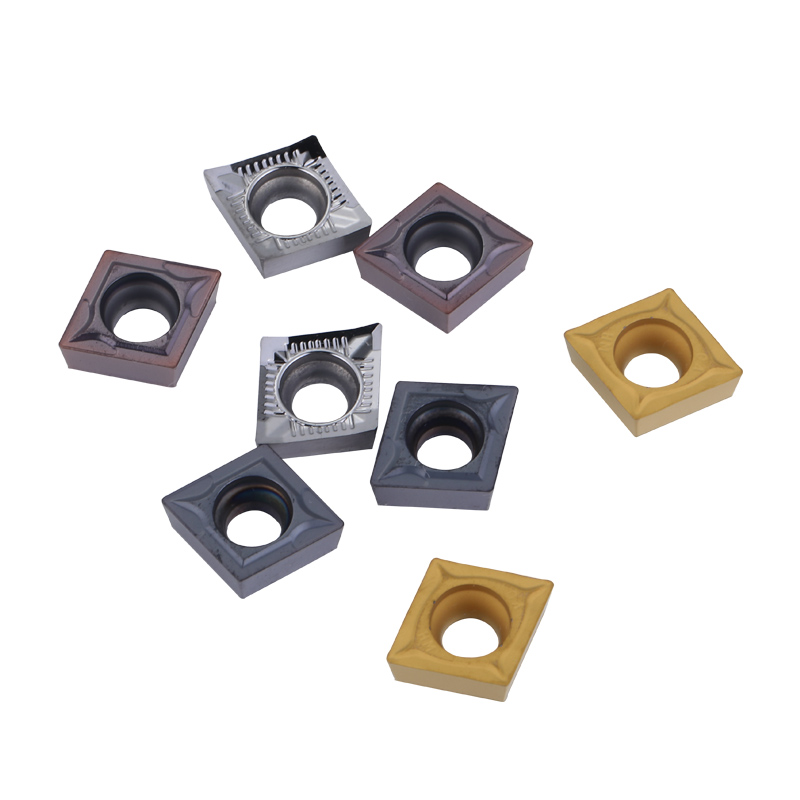

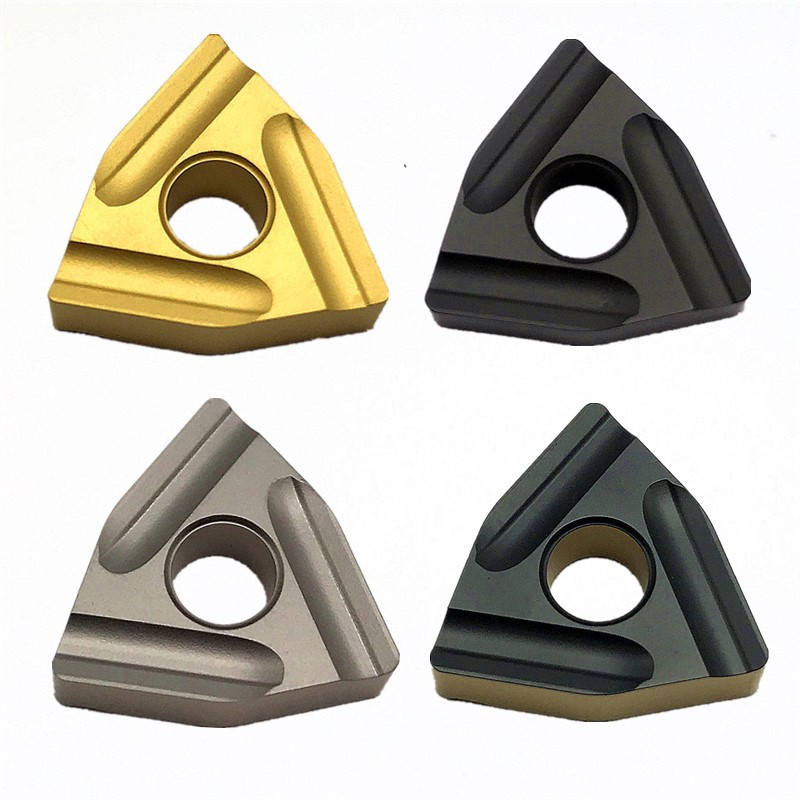

CNC periphery grinding machine for carbide turning inserts is a highly specialized piece of equipment used in manufacturing processes, particularly in the production of carbide cutting inserts used in turning operations on lathes.

CNC: CNC stands for Computer Numerical Control. This indicates that the machine is controlled by a computer, allowing for precise and automated control of the grinding process. CNC machines are highly versatile and can execute complex machining operations with high accuracy.

Periphery Grinding: As mentioned earlier, periphery grinding involves grinding the outer edges or periphery of a workpiece. In the context of carbide turning inserts, periphery grinding is essential for achieving precise dimensions and shapes on the cutting edges of the inserts. This is crucial for ensuring the inserts perform optimally during machining operations.

Carbide Turning Inserts: Carbide turning inserts are cutting tools used in turning operations on lathes. They are typically made of carbide, a hard and durable material that can withstand the high temperatures and forces generated during machining. These inserts are designed with specific geometries to facilitate efficient material removal and achieve desired surface finishes.

A CNC periphery grinding machine for carbide turning inserts would be specifically designed to automatically grind the periphery of carbide inserts to precise specifications. The CNC control allows for programmable parameters such as cutting speed, feed rate, and depth of cut, ensuring consistent and high-quality results across batches of inserts. This type of machine is essential in the production of cutting tools for metalworking industries, where accuracy and performance are critical.