Part Leveling Machines for Laser, Plasma, and Stamped Parts (Medium-Thickness Sheet Metal)

These Part Leveling Machines are designed for leveling medium-thickness laser-cut, plasma-cut, and stamped parts. Equipped with advanced features such as servo-driven automatic gap adjustment, these machines ensure high precision and efficiency in leveling medium-thickness metal sheets, which is essential in industries requiring precise sheet metal processing.

Key Specifications:

Width: 200-2200mm

Roll Diameter: 60mm

Rated Thickness: 1-6mm

Number of Rolls: 19 (Upper: 9, Lower: 10)

Leveling Roller Gap Adjustment: Four-point automatic adjustment, driven by servo motors

| Model | STR-60CNC | STR-80CNC | STR-100CNC | STR-·120CNC |

| Width (mm) | 400-2200 | 400-3800 | 400-3800 | 400-3800 |

| Roll Diameter (mm) | 60 | 80 | 100 | 120 |

| Rated Thickness (mm) | 1-6 | 1.5-8 | 3-12 | 4-16 |

| Maximum Thickness (mm) | 6 | 8 | 12 | 16 |

| Number of Rolls | 19 (Upper: 9, Lower: 10) | 19 (Upper: 9, Lower: 10) | 19 (Upper: 9, Lower: 10) | 19 (Upper: 9, Lower: 10) |

| Shortest Part (mm) | 15x120 | 40x150 | 60x180 | 60x200 |

| Leveling Speed (m/min) | 0-12 | 0-12 | 0-12 | 0-12 |

| Leveling Roller Gap Adjustment | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors |

| Voltage | 3-phase 380V | 3-phase 380V | 3-phase 380V | 3-phase 380V |

Key Features and Functions:

Automatic Gap Adjustment: The four-point automatic gap adjustment, driven by servo motors, ensures that the leveling process remains precise and efficient. This system automatically adjusts the roller gap to accommodate variations in material thickness, providing consistent flatness across all parts.

High Precision Leveling: The machine features 19 leveling rolls (9 upper and 10 lower) that work together to effectively level metal sheets. This ensures that laser-cut, plasma-cut, and stamped parts are uniformly flattened, removing any distortions or warping caused by the cutting or stamping processes.

Wide Processing Range: Capable of handling sheet metal thicknesses from 1mm to 6mm and widths from 200mm to 2200mm, the machine can process a wide range of parts. This makes it versatile for different applications across multiple industries.

Efficient Production: With automatic adjustments and servo-controlled precision, the machine minimizes downtime and improves production speed, making it ideal for high-volume environments where efficiency and consistency are key.

Durability and Reliability: The robust design and high-quality components ensure that the machine can handle demanding production schedules without compromising performance. The machine is built for long-term use, requiring minimal maintenance while delivering consistent results.

Applications:

These part leveling machines are ideal for leveling medium-thickness metal parts produced through laser cutting, plasma cutting, and stamping. Common applications include:

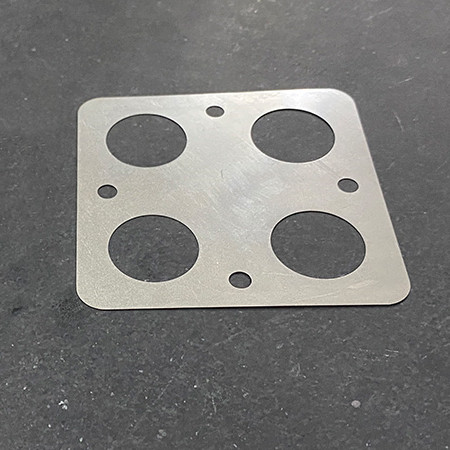

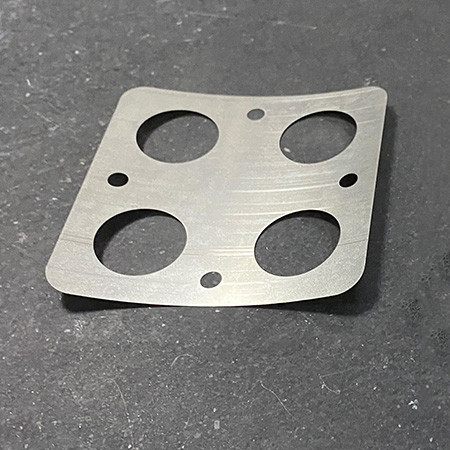

Laser-Cut Parts: Correcting distortions and warping in laser-cut metal sheets, ensuring a flat and even surface for further processing.

Plasma-Cut Parts: Leveling plasma-cut parts to remove any uneven surfaces or edges, improving the quality and accuracy of the part.

Stamped Parts: Flattening stamped metal components that may have experienced deformation during the stamping process, preparing them for subsequent operations such as welding or assembly.

Industries:

Automotive: Leveling parts used in car manufacturing, including body panels, chassis components, and structural elements.

Aerospace: Ensuring flatness and precision for aerospace components that require strict tolerances.

Construction: Leveling parts used in construction machinery or structural elements, ensuring they fit together precisely.

Electronics: Flattening metal sheets used in electronic devices and enclosures, where precision is key for proper assembly and functionality.

Benefits:

Consistent Flatness: The servo-driven automatic gap adjustment ensures uniform flatness across all processed parts, improving the quality and reducing the need for rework.

Improved Production Efficiency: With automatic leveling adjustments and high-speed operation, the machine helps to significantly reduce cycle times and improve overall production efficiency.

Reduced Material Waste: Accurate leveling minimizes material waste by ensuring that metal sheets are flattened correctly the first time, eliminating the need for further corrections.

High-Quality Results: The combination of precise gap adjustments, high-quality leveling rolls, and servo-controlled operation guarantees consistent results and improved dimensional accuracy across various metal parts.

User-Friendly: The machine’s automated functions and easy-to-use controls reduce the skill requirements for operators and minimize human error, ensuring more reliable results with less manual intervention.