Precision Laser Cutting Services for Framed SMT Stencils

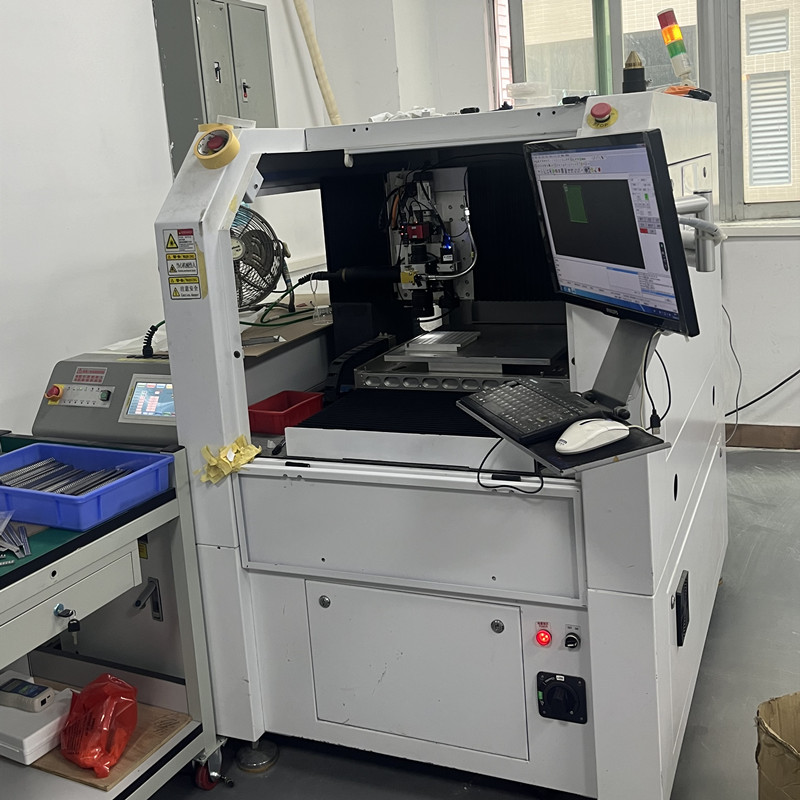

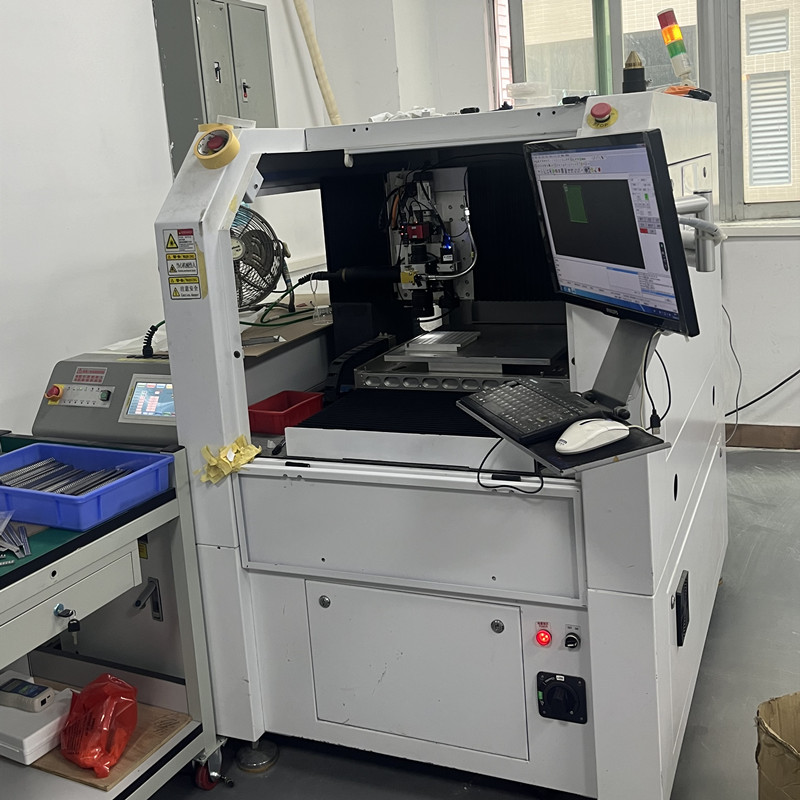

high-precision laser cutting services designed specifically for the production of Framed SMT Stencils. Our framed stencils are manufactured using state-of-the-art laser cutting equipment, providing superior accuracy, reliability, and performance for your surface mount technology (SMT) assembly processes.

Framed SMT stencils are ideal for high-volume production environments where stencil rigidity and ease of handling are crucial. With our extensive selection of standard frame sizes, we offer solutions to meet the diverse needs of PCB manufacturers and assembly houses worldwide.

Available Frame Options

We provide a range of Cast and Extruded Frames, ensuring you have the right option for your production requirements:

| Frame Type | Frame Size | Maximum Foil Size |

| Cast 8"x10" | 7"x9" | 5"x7" |

| Cast 10"x10" | 9"x9" | 7"x7" |

| Cast 12"x12" | 11"x11" | 9"x9" |

| Extruded 12"x12" | 11"x11" | 9"x9" |

| Cast 12"x17" | 11"x16" | 9"x14" |

| Extruded 12"x17" | 11"x16" | 9"x14" |

| Cast 15"x15" | 14"x14" | 12"x12" |

| Extruded 15"x15" | 14"x14" | 12"x12" |

| Cast 20"x20" (OD 23”x23”) | 19"x19" | 17"x17" |

| Extruded 20"x20" (OD 23”x23”) | 19"x19" | 15"x15" |

| Extruded 29"x29" | 24"x24" | 22"x22" |

Note:

Cast Frames are solid aluminum, offering superior strength and durability.

Extruded Frames are hollow aluminum, providing lightweight handling and reduced costs.

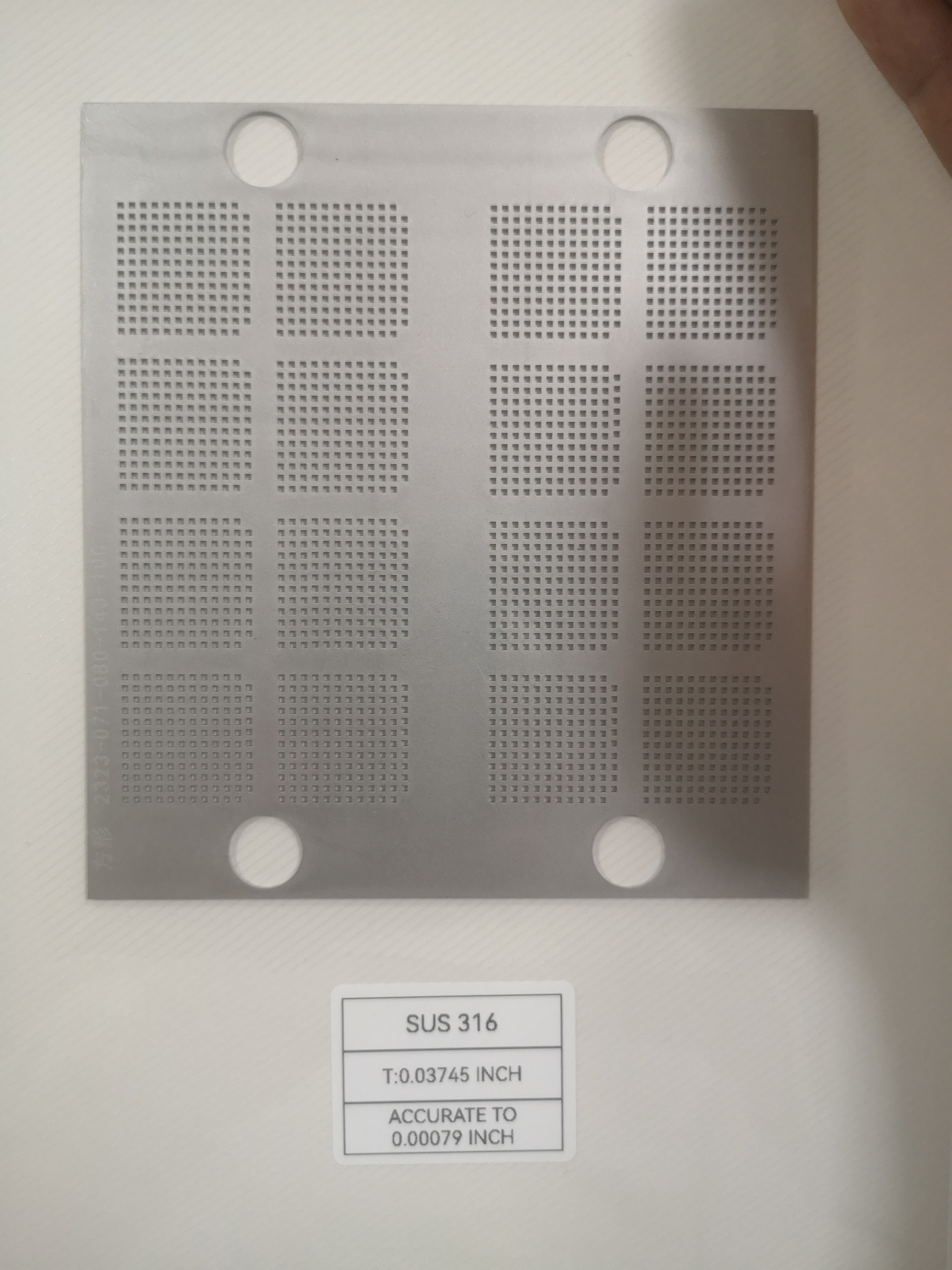

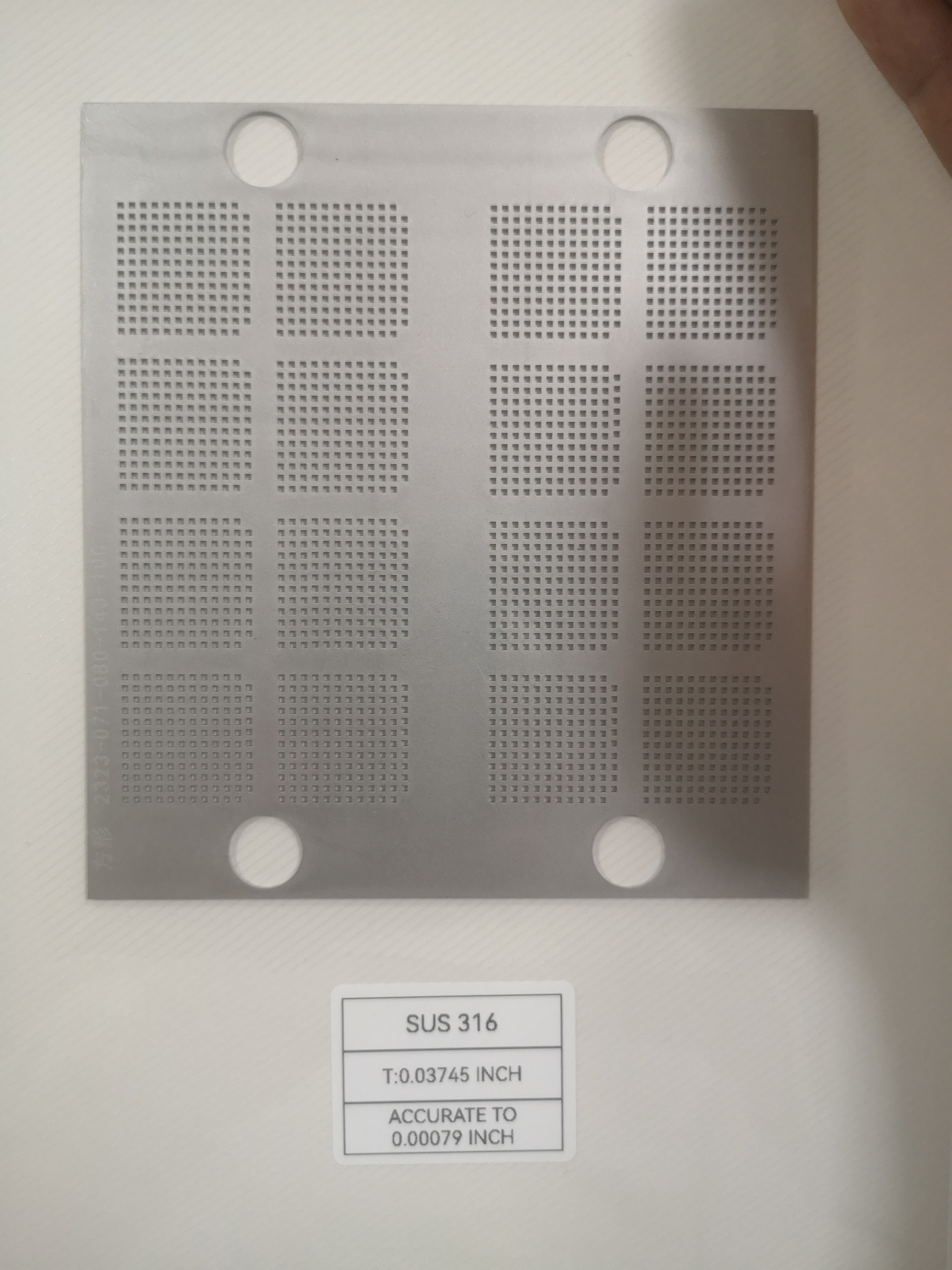

Technical Specifications

| Specification | Details |

| Technology Used | 100% Laser Cut |

| Material | High-Grade Stainless Steel |

| Stencil Thickness | .002 to .016 Inches |

| Minimum Cut Width | .002 Inches |

| Maximum Stencil Size | 29" x 29" Inches |

| Aperture Tolerance | Within .00025 Inches |

| Fiducial Marks | Supported |

| Panelized Data | Supported |

Our precise laser cutting technology ensures clean, burr-free edges, optimal paste release, and exact aperture sizes, which are critical for achieving high-quality, repeatable solder paste deposition.

Why Choose Our Framed SMT Stencils?

1. Superior Precision and Quality

Our 100% laser-cut stencils are crafted to provide the sharpest, most consistent apertures possible. The extreme precision of our laser systems ensures perfect registration and consistent solder paste volumes, even for the most demanding fine-pitch applications.

2. Durable Frame Options

Both cast and extruded frames are built to withstand rigorous usage in high-volume production environments. Cast aluminum frames offer enhanced strength and rigidity, while extruded frames deliver lightweight flexibility at a lower cost.

3. Wide Range of Sizes

We offer a comprehensive selection of frame sizes, making it easy to match your stencil requirements with your printer specifications and production volumes.

4. Quick Turnaround Times

Need your stencil in a hurry? No problem. We offer expedited manufacturing and shipping options to meet tight project deadlines without compromising on quality.

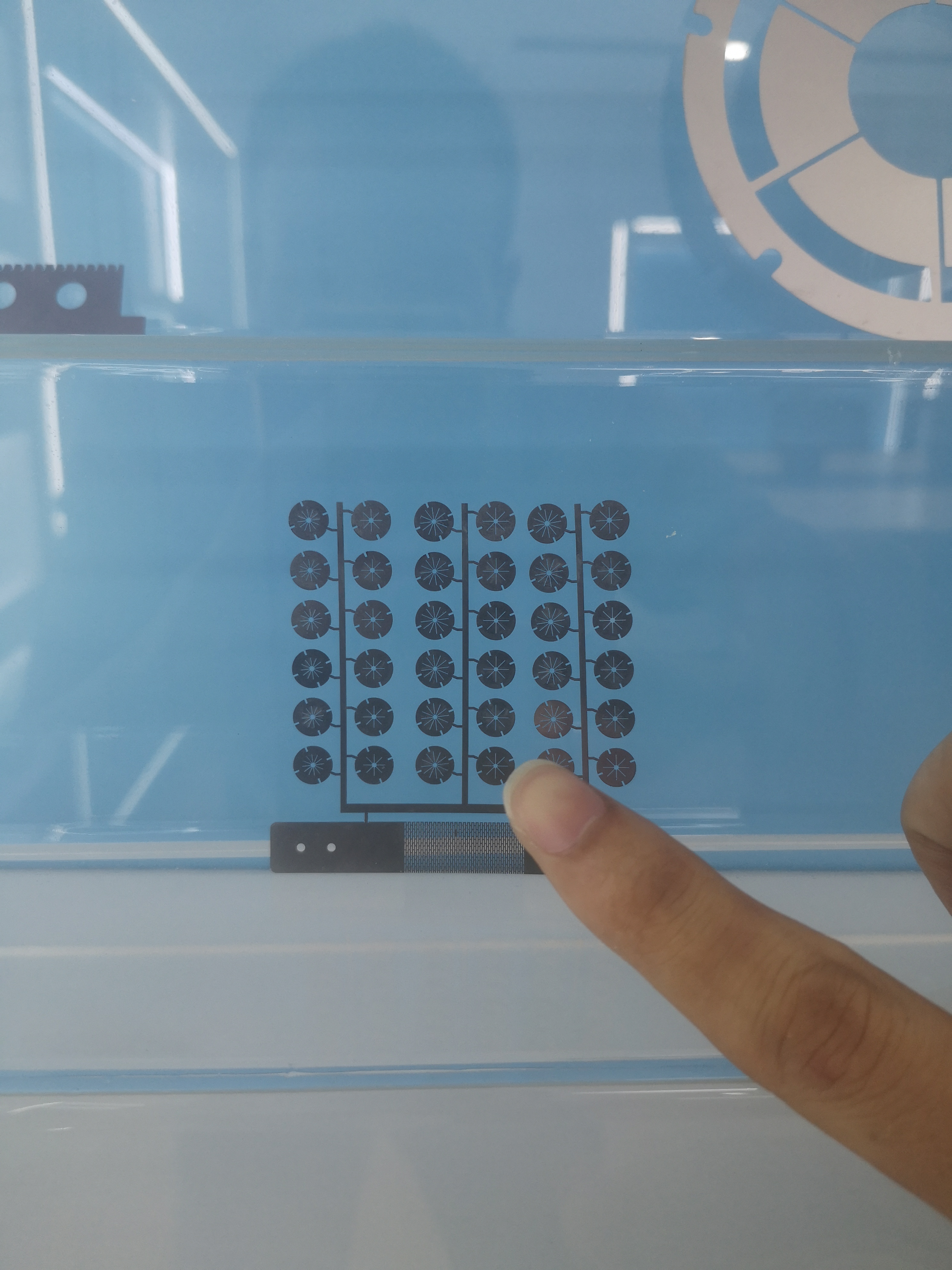

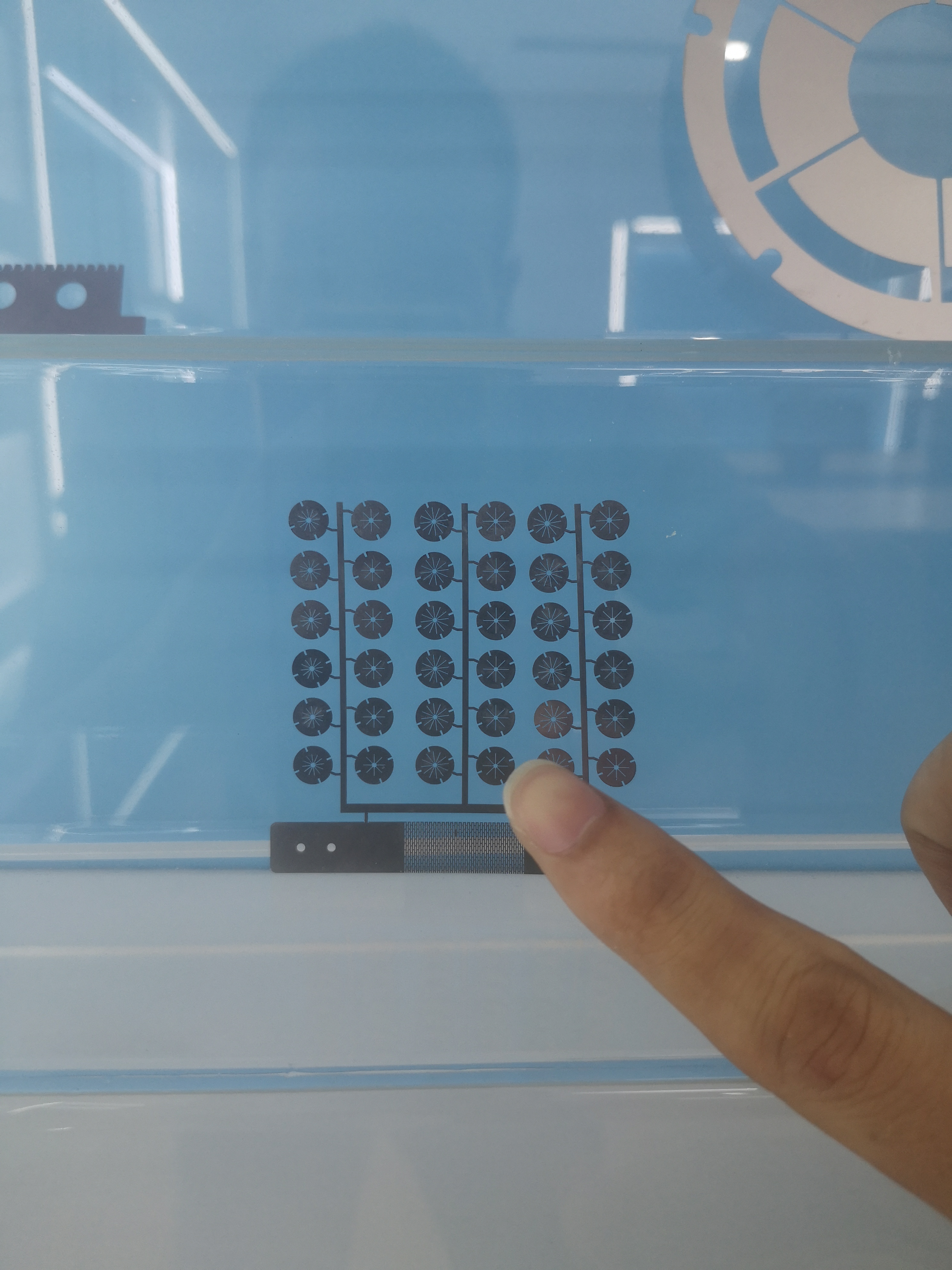

5. Support for Complex Designs

Whether you need fiducial marks, stepped stencils, panelized designs, or specialized aperture shapes, we can accommodate complex PCB designs with ease and precision.

Applications

Our Framed SMT Stencils are used across a wide range of industries and applications, including:

Consumer Electronics: Smartphones, tablets, wearables

Automotive Electronics: Advanced driver assistance systems (ADAS), sensors

Medical Devices: Miniature PCB assemblies for diagnostics and treatment devices

Aerospace and Defense: High-reliability PCBs for avionics and military applications

Telecommunications: 5G infrastructure, network devices

Industrial Automation: Robotics, control systems

Our stencils support all SMT assembly techniques, including fine-pitch components, micro BGAs, 01005 chips, and ultra-small passive components.

Value-Added Services

Data Verification and Optimization: We analyze your Gerber files and optimize aperture designs for better print performance.

Step-Down and Step-Up Stencils: For boards with mixed component heights.

Nano Coating Options: Available to enhance paste release and stencil lifespan.

Custom Frame Solutions: Bespoke frame sizing and design based on specific customer needs.

Ordering Process

Submit Gerber Files: Upload or email your PCB design files.

Review and Confirmation: Our engineering team reviews your data and confirms details.

Fabrication: Using our high-precision laser cutting systems.

Quality Inspection: Every stencil undergoes thorough dimensional and visual inspection.

Packaging and Delivery: Secure packaging to prevent damage during transit.