✅ RRP5340C Wet Wide Belt Sander | 3-Station | PLC Touch Screen Control | Magnetic Conveyor

Product Introduction:

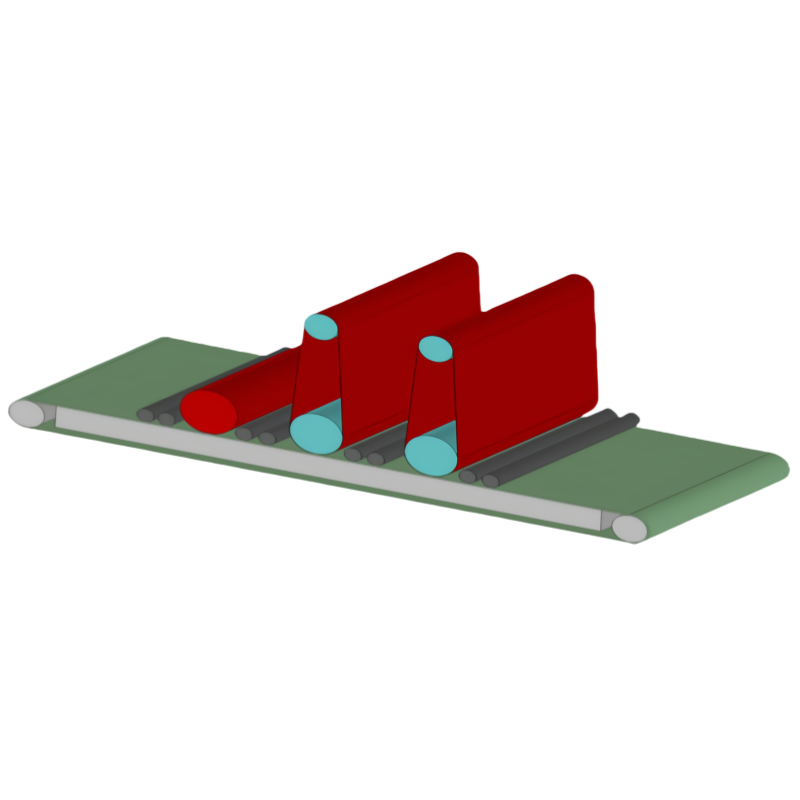

The RRP5340C Wet Wide Belt Sander is a premium, industrial-grade sanding and finishing machine designed specifically for deburring, oxide removal, edge rounding, and fine surface finishing of metal sheets and fabricated parts. Equipped with three processing stations, including two sanding heads and one brush head, it delivers a one-pass solution for comprehensive metal finishing tasks.

A standout feature of the RRP5340C is its magnetic conveyor worktable, providing exceptional holding force for ferrous metal parts during processing. This ensures high stability, consistent contact, and uniform results, even when handling small or thin components that would otherwise shift during machining.

Built with a wet processing system, the RRP5240C eliminates heat distortion, reduces airborne dust, and significantly increases the lifespan of sanding belts and brushes. The PLC touch screen control panel offers intelligent operation, easy program setting, real-time monitoring, and fast recipe changes—making this machine a go-to solution for metal fabrication workshops, laser cutting services, and OEM manufacturers looking for efficiency and consistency.

✅ Key Features and Advantages:

✔️ Magnetic Conveyor Worktable:

✔️ Three-Station Wet Sanding System:

Two abrasive belt sanding heads for heavy burr removal, oxide scale removal, and uniform surface graining.

One rotary brush head for edge rounding and achieving a smooth radius on sharp edges.

Water-cooling system minimizes heat impact on materials, preventing warping and discoloration.

✔️ PLC Touch Screen Controller:

Fully programmable with recipe storage.

Intuitive interface for adjusting belt speed, feed rate, and brush speed.

Fault diagnosis and maintenance reminders reduce downtime.

✔️ Efficient Deburring and Finishing:

Achieves high-quality finishes on laser-cut, plasma-cut, punched, or sheared metal parts.

Capable of oxide layer removal, slag removal, and edge rounding in one pass.

✔️ Superior Surface Quality:

✔️ Safety and Environmental Friendliness:

Wet sanding technology reduces heat, prevents fire hazards, and controls dust.

Integrated water circulation with filtration system ensures sustainable operation.

✅ Technical Specifications (RRP5340C):

| Specification | Value |

| Working Width | 400 mm |

| Max Working Thickness | 60 mm |

| Min Working Length | 150 mm |

| Number of Stations | 3 (2 sanding heads + 1 brush head) |

| Abrasive Belt Size | 1900 × 400 mm |

| First Sanding Head Motor | 7.5 kW |

| Second Sanding Head Motor | 7.5 kW |

| Brush Head Motor | 5.5 kW |

| Conveyor Motor Power | 1.5 kW |

| Lifting Motor Power | 0.37 kW |

| Total Installed Power | Approx. 23 kW |

| Conveyor Speed | 0.5 – 6 m/min (Adjustable) |

| Abrasive Belt Speed | 12 m/s |

| Brush Speed | Frequency adjustable |

| Cooling Method | Water-cooled wet processing with circulation and filtration |

| Control System | PLC Touch Screen |

| Conveyor Type | Magnetic Conveyor |

| Machine Dimensions (L×W×H) | 2500 mm × 1600 mm × 2000 mm |

| Net Weight | ~2200 kg |

✅ Main Functions:

Deburring: Removes sharp burrs and splatter from laser, plasma, or flame-cut parts.

Oxide Removal: Eliminates oxide films, improving welding and coating adhesion.

Edge Rounding: Produces rounded, smooth edges (up to R2 radius) for improved safety and coating durability.

Slag/Dross Removal: Efficiently removes tough slag from plasma-cut steel.

Surface Graining & Finishing: Creates consistent satin or hairline finishes, enhancing product appearance.

✅ Applications:

Sheet metal fabrication shops

Laser cutting and plasma cutting workshops

Kitchenware and appliance manufacturers

Elevator panels and architectural cladding

Furniture hardware finishing

Sanitaryware and plumbing component production

General metal processing industries

✅ Material Compatibility:

✅ Carbon Steel

✅ Stainless Steel (including thin sheets)

✅ Mild Steel with plasma or flame cut surfaces

❌ Non-ferrous metals (aluminum, copper) are not suitable for magnetic conveyor setups (alternative options available).

✅ Typical Use Cases:

Post-laser cutting part finishing

Pre-painting surface preparation

Deburring sharp-edged brackets and enclosures

Edge rounding for galvanized steel components

Finishing automotive structural parts

Removing oxide scale from flame-cut plates

Achieving cosmetic finishes on stainless steel panels

✅ Benefits for Your Factory:

✔️ Faster throughput with fewer passes

✔️ Reduced labor cost with automation

✔️ Superior, consistent surface quality

✔️ Less tool consumption due to longer abrasive life

✔️ Improved workplace safety—no airborne dust

✔️ Lower energy cost with efficient motor setup

✔️ Multi-functionality saves factory floor space

✅ Summary:

The RRP5340C Wet Wide Belt Sander with Magnetic Conveyor is your ideal solution for industrial-scale metal finishing, combining deburring, oxide removal, edge rounding, and surface conditioning into one efficient process. It offers safe, dust-free wet processing, consistent results, and high efficiency for ferrous metal parts—perfect for modern, high-demand manufacturing environments.