400mm Wet Wide Belt Sander – RRR5340

Three-Station Deburring, Edge Rounding & Polishing Machine with Two Sanding Belts & Nylon Fiber Wheel

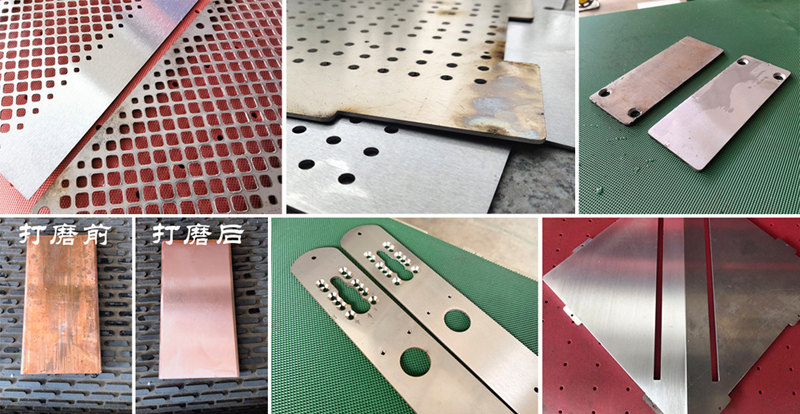

The RRR5340 400mm Wet Wide Belt Sander is a high-performance machine designed for deburring, edge rounding, and surface finishing of laser-cut and stamped sheet metal. Equipped with two sanding belts and one Nylon Fiber Wheel Flap Polishing Wheel, this machine offers a comprehensive processing solution, ensuring uniform material removal and a high-quality surface finish.

This model is available in two configurations:

Magnetic Conveyor Worktable – Ensures secure hold-down of small and thin metal parts during processing.

Non-Magnetic Conveyor Worktable – Provides flexibility for general metal sheet processing.

By integrating wet sanding technology, the RRR5340 effectively minimizes heat buildup, reduces dust, and extends the life of abrasive materials, making it ideal for stainless steel, aluminum, and carbon steel applications.

Features & Applications

Three-Station Configuration:

Station 1 & 2: Two abrasive belts provide sequential material removal for a smooth surface and burr-free edges.

Station 3: A Nylon Fiber Wheel Flap Polishing Wheel delivers a uniform, polished finish with enhanced edge rounding.

High-Efficiency Deburring: Removes sharp burrs and rough edges from laser-cut, stamped, plasma-cut, and flame-cut metal parts.

Edge Rounding & Finishing: Achieves smooth, rounded edges for enhanced safety, coating adhesion, and part durability.

Nylon Fiber Polishing Wheel: Provides consistent fine finishing, ensuring a satin-like surface texture on metal parts.

Wet Sanding Technology: Prevents overheating, reduces airborne dust, and extends belt lifespan.

Versatile Material Compatibility: Works with stainless steel, carbon steel, aluminum, and non-ferrous metals.

Adjustable Feed Rate: Allows customized processing speeds for different materials and surface requirements.

Magnetic vs. Non-Magnetic Conveyor:

Magnetic Conveyor Worktable: Designed for thin metal parts, ensuring firm hold-down during processing.

Non-Magnetic Conveyor Worktable: Suitable for general sheet metal processing, offering greater flexibility.

Compact & Sturdy Design: Guarantees reliable, long-lasting performance in industrial settings.

Technical Specifications

| Parameter | Unit | RRR5340 |

|---|---|---|

| Max Working Width | mm | 400 |

| Max Working Height | mm | 60 |

| Min Working Length | mm | 150 |

| 1st Sanding Belt Power | kW | 7.5 |

| 2nd Sanding Belt Power | kW | 5.5 |

| 3rd Polishing Wheel Power | kW | 5.5 |

| Rotary Motor Power | kW | / |

| Feed Motor Power | kW | 1.5 |

| Lifting Motor Power | kW | 0.37 |

| Oscillating Motor Power | kW | / |

| Vacuum Motor Power | kW | / |

| Machine Dimensions | m | 2.4 × 1.5 × 1.8 |

| Machine Weight | kg | 1500 |

| Abrasive Belt Size | mm | 1520 × 400 |

| Polishing Wheel Type | - | Nylon Fiber Wheel Flap |

| Worktable Options | - | Magnetic Conveyor / Non-Magnetic Conveyor |

Applications

The RRR5340 Wet Wide Belt Sander is an ideal solution for industrial applications requiring high-quality deburring, edge rounding, and polishing of metal components. It is widely used in:

Laser-cutting workshops – For removing burrs and refining edges.

Metal stamping factories – For deburring stamped metal parts and enhancing surface quality.

Aerospace & automotive industries – Ensuring uniform finishing and precision edge rounding for high-performance metal parts.

Stainless steel & aluminum processing plants – Providing fine polishing and a consistent finish.

Fabrication & manufacturing – Delivering smooth, defect-free surfaces before coating or welding.

The combination of sanding belts and a Nylon Fiber Wheel Polishing System makes the RRR5340 a versatile, cost-effective, and efficient solution for achieving superior metal surface quality in industrial production.