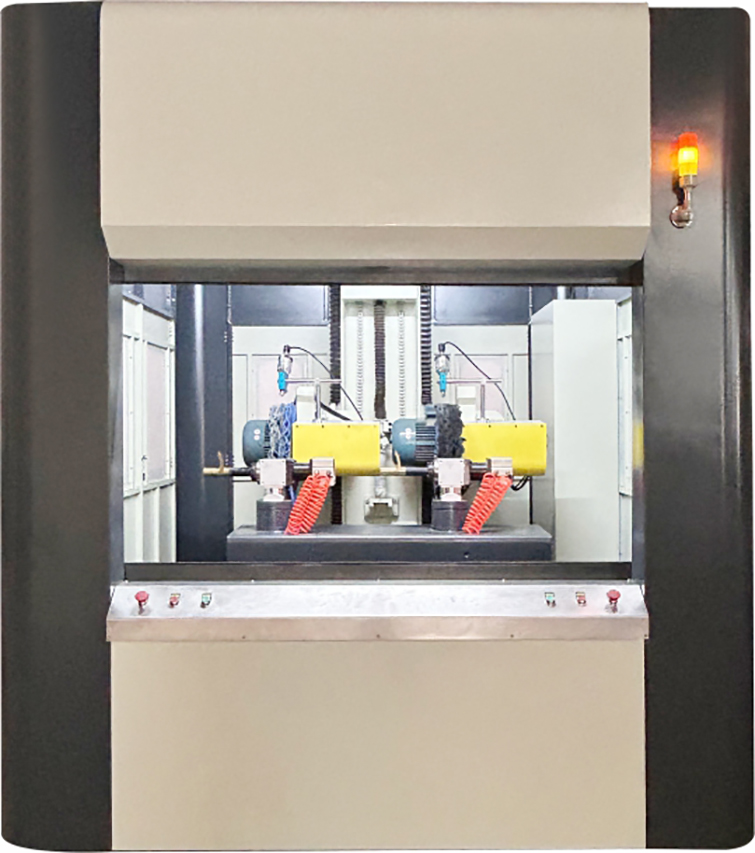

Universal CNC Machine for Polishing and Brightening Smart Door Lock Components

The Universal CNC Machine for Polishing and Brightening is a highly efficient, multi-purpose solution designed to polish and brighten a wide range of components, including base plates, exterior and interior handles, and other parts used in the manufacturing of smart door locks. This advanced CNC machine is built to deliver high-quality finishes with low operating costs, making it an excellent choice for industries where precision, flexibility, and speed are crucial.

Key Features:

Low Operating Costs: The machine is designed to be energy efficient, ensuring that operational expenses remain minimal. It utilizes minimal amounts of mops and polishing compounds, reducing material costs while still achieving exceptional results. This low-cost approach makes it ideal for high-volume production environments.

High Production Capacity: The machine's design allows for simultaneous polishing of two parts of the same model in each cycle. This ability significantly increases throughput and reduces processing time, making it a highly productive tool for manufacturing companies.

Multi-Purpose Functionality: This CNC machine is versatile and capable of polishing a variety of different components. From smart door lock parts like base plates, exterior handles, and interior handles to other bathroom fittings like faucets and shower handsets, the machine can handle numerous typologies and materials with ease. This multi-purpose capability ensures that manufacturers can use a single machine for a wide range of polishing tasks.

Flexible Production: One of the standout features of this machine is its flexibility. It boasts quick setup times and allows for rapid changes in production. Changing the grippers and polishing mops can be done in a matter of seconds, minimizing downtime and ensuring that the production process remains efficient. This flexibility is key in environments where the production schedule requires fast adaptation to different parts and models.

Superior Surface Finish Quality: The CNC machine guarantees a homogeneous surface finish without imperfections, ensuring that the polished products meet the highest standards. Whether it's for the fine details of a smart door lock handle or the sleek surface of a faucet, the quality of the finish remains consistent across all parts processed.

Applications:

Deburring: The machine can be used to remove burrs from metal parts, ensuring that sharp edges are smoothed out and the components are safe to handle.

Grinding: The grinding function allows the CNC machine to smooth rough surfaces and prepare them for further finishing or polishing processes.

Polishing: The machine excels at polishing metal surfaces to a high-gloss finish, ensuring that the components, whether they are handles, faucets, or any other fittings, look pristine and refined.

Satin Finish: For those parts requiring a satin finish, the machine can achieve this look by adjusting the polishing parameters to create a fine, brushed appearance without a high-gloss shine.

Easy and Intuitive Programming:

The CNC machine features Teach-In Programming, which makes it user-friendly and intuitive. Operators can easily program the machine to perform a variety of tasks, including polishing, deburring, and grinding, without the need for extensive training. The simple, step-by-step programming process ensures that users can set up new production jobs quickly and accurately, minimizing human error.

Simultaneous Processing of Two Parts:

One of the key advantages of this machine is its ability to simultaneously process two parts of the same model in one cycle. This dual-processing capability increases production efficiency, reduces cycle times, and maximizes the overall output. Whether processing smart door lock components or bathroom fixtures, manufacturers can significantly enhance productivity.

High Adaptability:

The machine is designed with high adaptability in mind, allowing it to handle a wide range of geometries and materials. It is capable of processing different types of finishes, from high gloss to satin, making it a versatile tool for a wide variety of industries. The flexibility to process different materials such as brass, zinc, and other metals ensures that the machine can be used across multiple sectors, including smart lock manufacturing, bathroom fixture production, and more.

Rapid Model Changeover:

In industries where product lines can change frequently, the ability to quickly switch models is essential. The Universal CNC Machine allows for fast model changeovers, reducing the time required to reconfigure the machine. Operators can change the model in just a few seconds, ensuring that production stays on track and reducing downtime.

Applications Across Various Industries:

This Universal CNC Machine is ideal for polishing and brightening a variety of products, including but not limited to:

Smart Door Lock Components: Base plates, exterior and interior handles, and other critical parts in smart lock systems.

Faucets: From bathroom faucets to kitchen faucets, ensuring a polished, shiny finish that enhances product appeal.

Bathroom Fittings: Handles, shower heads, and other fixtures can be polished to perfection.

Shower Handsets: Ensuring a high-quality, smooth, and bright finish on shower components.

Whether for high-precision polishing, satin finishing, or deburring, the machine is designed to meet the diverse needs of the modern manufacturing industry.

Conclusion:

The Universal CNC Machine for Polishing and Brightening is a powerful, flexible, and cost-effective tool that can significantly enhance the production capabilities of manufacturers in the smart door lock and bathroom fixture industries. Its ability to handle a wide variety of components, coupled with its high productivity, flexibility, and superior finish quality, makes it an indispensable asset for manufacturers looking to improve both the quality and efficiency of their production lines. With easy programming, rapid changeover, and low operating costs, it is the ideal solution for businesses aiming to stay competitive in the fast-paced market.