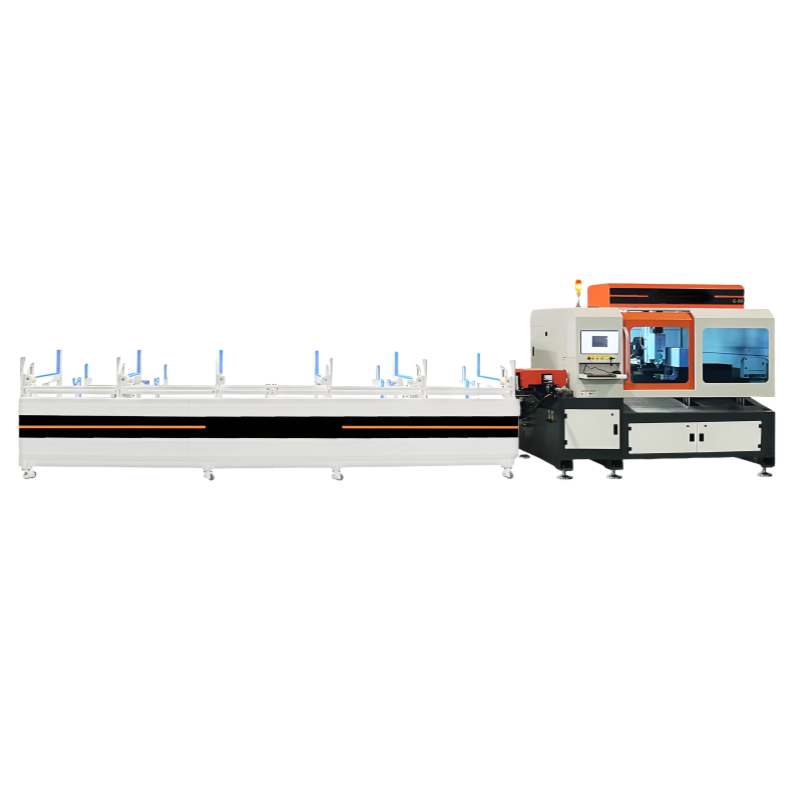

Equipment Name: G90K 3D Laser Tube Cutting Machine (Small Double V-Groove Beveling)

Equipment Image:

Equipment Image:

G90K (Automatic/Semi-Automatic/Manual)

Features Introduction:

The machine is equipped with an automatic loading rack, saving time and labor, with a simple structure and easy operation.

The efficiency is 5-6 times that of a standard tube cutting machine.

The tail material blind spot is small, saving materials and reducing subsequent processes.

The remaining tail material length can be controlled freely, even to zero, greatly reducing material waste.

Adaptive cutting: The standard configuration includes an integrated height adjuster, easily handling deformed tubes.

(Images are for reference only; actual appearance and dimensions are subject to the final equipment delivered.)

Machine Bed Assembly:The machine bed features a compact structure and occupies minimal space, using strict welding and annealing processes to ensure long-term stable operation and cutting precision. It can meet 24-hour industrial production needs while ensuring no deformation over the machine bed's lifetime.

(Images are for reference only; actual appearance and dimensions are subject to the final equipment delivered.)

Industry-Leading Laser Generator: Chuangxin/Reicou

Modular design, stable performance

The internal structure uses optical-electronic module separation design, ensuring more stable operation

Easy maintenance, reduces downtime

The optical module, electrical module, control unit, and driver unit can be directly replaced, upgraded, and maintained by the client

Customizable to meet various needs

Users can select fiber optics with different core diameters to meet diverse processing requirements

Uniform energy distribution and stable processing

Reduces welding spatter, improving the cutting ability for thick plates

Suitable for various applications

Compatible with laser processing heads, galvanometers, and system integration with robots, machine tools, etc., for laser precision cutting and welding, applicable in industries such as 3C, hardware, medical, automotive, and aerospace.

Fiber Optic 3D Laser Cutting Head: Osprey

High adaptability:

Equipped with various fiber interfaces such as QBH and QCS, compatible with various mainstream lasers

Excellent design:

Optimized optical configuration and smooth, efficient airflow design significantly improve cutting quality and efficiency

Slim nozzle design:

Modular, slim nozzle design reduces interference with workpieces

Compact structure:

Lightweight and small size reduce robot load requirements, improving cutting speed and quality

LCN03A Manual Focusing

Operating System: Bystronic FSCUT3000

EtherCAT bus control, fast communication speed, and strong anti-interference

Can freely add axes and control signal modules

Provides customized main design functions for customers

Can control 256 axes, and each EtherCAT segment can accommodate up to 65,535 devices

Standard nesting eliminates the need for model selection and hardware matching, allowing immediate installation and use.

High-Precision Chuck:

The precision chuck features an integrated design with good sealing and dust-proof effects, effectively preventing cutting dust from entering the chuck and impacting cutting precision and equipment lifespan. The built-in pneumatic cylinder allows for easy installation, and the clamping and releasing action is performed through side air input, suitable for a full range of tube sizes, improving production efficiency. The four-jaw guiding system uses a rail mechanism to ensure linearity and stability. The repeat positioning accuracy is 0.01 mm, with a theoretical maximum speed of 200 r/min. (The empty travel speed should be reduced with heavier tube weights.) When cutting tail material, the front chuck can move to avoid interference, ensuring the precision of the last piece and maximum control over the tail length.

Transmission System:

The machine uses a gear and rack transmission structure for feed motion, with the Z-axis employing imported ground ball screws to ensure high-speed, high-precision, and high-reliability performance. The gear, rack, ball screw, and linear guideways are equipped with sealed dustproof devices to prevent frictional movement and dust contamination, extending the life of transmission parts and ensuring motion precision. The machine is equipped with an automatic lubrication system for regular lubrication of the gear, rack, and ball screw systems.

Pneumatic System:

The cutting gas is independently controlled in three routes, enabling automatic switching between air, nitrogen, and oxygen (optional) during the punching process, with real-time pressure control and flexible cutting process adjustments.

Single-Axis Servo System:

The advanced motion control algorithm ensures smoother, faster operation and more precise positioning, guaranteeing high-speed stable operation and acceleration capabilities.

Cooling System: Hanli Brand Chiller

High-quality stainless steel chiller pump with high flow, high head, low noise, and long lifespan

Stainless steel water tank, pipeline, and valve parts prevent rust

The control system uses a computer controller with CPU automatic control, offering simple, intuitive operation. The control precision is up to ±0.1°C, with automatic fault diagnosis to help users quickly address issues, avoiding damage to components and equipment.

The "dual-temperature" precision water cooler provides stable, accurate water temperature control for the laser while offering another water circuit for lens cooling, solving condensation damage issues during low-temperature cooling.

G90K Equipment Parameters:

Machine Name: Small Double V-Groove Beveling

Model: G90K

Laser Power (W): 1500-3000W

Cutting Tube Diameter (MM): 10-90MM

Repeat Positioning Accuracy (MM): ±0.02

Tube Processing Range (MM): ≈6250

Machine Dimensions (MM):

Manual Loading: 357817001950

Semi-Automatic: 930017001950

Fully Automatic: 930019001950

Machine Weight (T): ≈2.5

Acceleration (G): ≈1.5G

Tail Material Length (MM): ≈40MM (for non-beveling final cut)

Note: Specifications may change without notice. The final technical parameters are based on the actual order agreement.

G90K Configuration List:

| Serial No. | Name | Brand/Origin | Model/Specifications | Quantity | Remarks |

| 1 | Fiber Laser Source | Chuangxin/Reicou |

| 1 set |

|

| 2 | Fiber Laser Cutting Head | Osprey |

| 1 set |

|

| 3 | Fiber Control System | Bystronic |

| 1 set |

|

| 4 | Rotary Pneumatic Chuck | Biote/Other Optional |

| 1 set |

|

| 5 | X.Y.Z Axis Slide | SHAC/AirTAC |

| 3 sets |

|

| 6 | X.Y.Z Axis Rail | SHAC/AirTAC |

| 3 sets |

|

| 7 | X.Y Axis Rack | Taiwan Liangchi/Taiwan Jingte |

| 2 sets |

|

| 8 | X.Y.Z.U Axis Servo Motor & Driver | Delta/Hawei |

| 4-5 sets |

|

| 9 | Pneumatic System | AirTAC |

| Several |

|

| 10 | Electrical Proportional Valve | AirTAC/SMC |

| 1 unit |

|

| 11 | Machine Accessories | Standard |

| 1 set |

|

| 12 | Machine Bed | Standard |

| 1 set |

|

| 13 | Control Cabinet | Standard |

| 1 set |

|

| 14 | Circuit Breakers, Relays | Schneider/DELIXI |

| 1 set |

|

| 15 | Power Supply | Schneider/DELIXI |

| 1 set |

|

| 16 | Cooling System | Hanli |

| 1 set |

|

| 17 | Loading System | Fully Automatic/Semi-Automatic Rack |

| 1 set |

|

Laser Consumables and Special Parts List:

| Serial No. | Name | Specifications | Unit | Quantity | Remarks |

| 1 | Optical Lens | Osprey | Piece | 5 |

|

| 2 | Cutting Nozzle | Osprey | Piece | 5 |

|

| 3 | Ceramic Ring | Osprey | Piece | 5 |

|

Note: Specifications may change without notice. The final technical parameters are based on the actual order agreement.

Equipment Usage Analysis:

| Serial No. | Usage Analysis |

| 1 | Fiber laser source environmental requirements: Temperature: 15-35°C, relative humidity: <85% |

| 2 | On-site distribution cabinet: 380V 50Hz with short circuit protection |

| 3 | Dedicated grounding required with grounding resistance not exceeding 4Ω |

| 4 | Necessary lifting equipment and personnel |

| 5 | Materials required for equipment on-site debugging (e.g., steel plates) |

| 6 | Auxiliary conditions required for laser cutting equipment: |

| (1) Cutting gases (N2, O2) |

|

| (2) Water and oil-free compressed air supply system |

|

Equipment Voltage and Gas Requirements:

| Serial No. | Voltage and Gas Requirements |

| 1 | Rated input voltage: 380V/50Hz, voltage stability: ±5% (recommended with voltage stabilizer) |

| 2 | Compressed air supply system (recommended with air storage tank and dryer) |

| Rated pressure: High-pressure ≥1.6Mpa, low-pressure ≥0.6Mpa |

|

| Airflow: ≥1.0m³/min, Volume: 1m³ |

|

| 3 | Auxiliary cutting gases with purity requirements |

| Nitrogen (N2) ≥99.99% |

|

| Compressed air ≥1.6Mpa (for tubes ≤3mm in diameter, carbon steel, stainless steel can use air cutting for lower cost) |

|