Handheld welding head technical parameters:

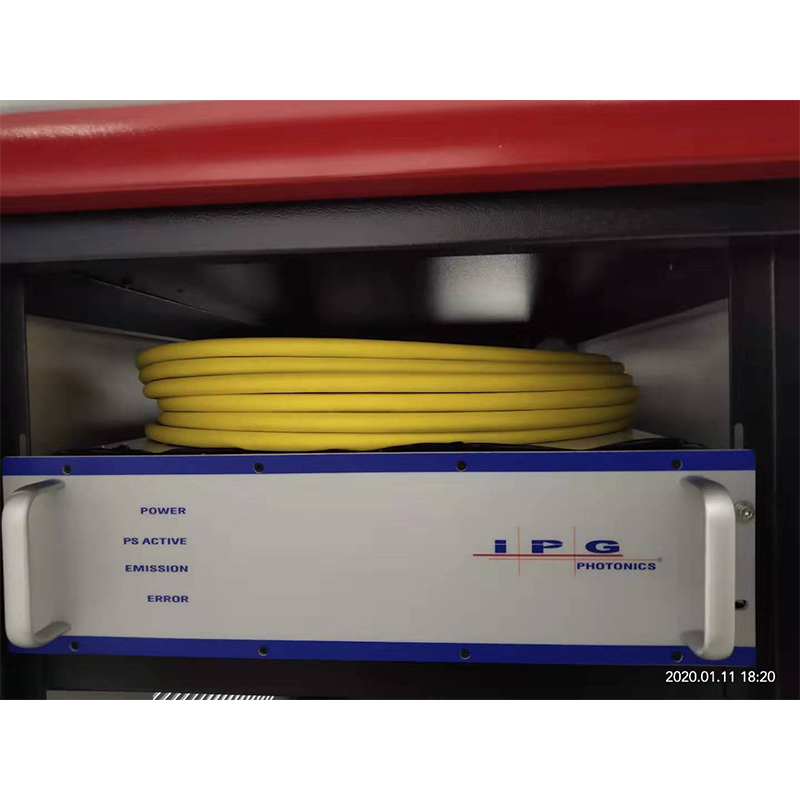

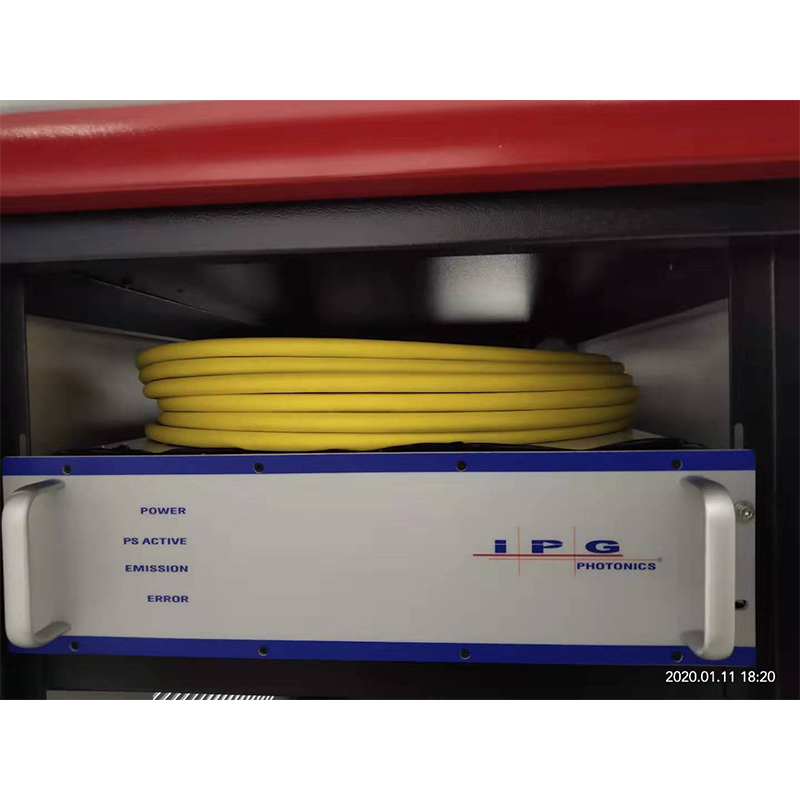

Interface type QBH

Power range 2000W

Laser wavelength 1064-1080nm

Light spot adjustment (0.2-5) mm

Collimated focal length 50mm

Focusing focal length 120/150mm

Protective lens D20X2mm

Cooling method Water cooling

Handle weight 1.2KG

Mode Selection Dot-Line-Circle-Double 0-Triangle-8 Word

Laser Safety, Operational Safety Notices:

Please pay attention to the following when operating the installation:

1) Please use this product correctly according to the instructions for use, do not damage the power supply and do not step on, twist or pull the cable. Damaged cables can cause electric shock, short circuit, and fire.

2) Please turn off the power to stop the operation when there are abnormal phenomena such as burning smell, abnormal sound, abnormal heat, smoke, etc., otherwise there will be danger of electric shock, fire, etc.

3) Foreign objects, especially metal or conductive objects, should be avoided in the circuit to prevent short circuit or cause failure. Do not use it in a humid environment. Water in the electrical part may cause electric shock or short circuit. It is powered on.

4) Please wear protective glasses and safety gloves during laser processing. It is strictly forbidden to point the muzzle of the gun to the human body and eyes after the power is turned on and after the laser power is turned on. After the processing is terminated, the workpiece is still in a high temperature state, please wear gloves to touch the workpiece.

5) During welding, the welding parts and the console are prohibited from being connected to the ground, and the correct use is safe to contact the light. The muzzle is strictly prohibited from sight glasses and skin.

Boot sequence

The voltage used by this product is AC 200V. Connect the power cord to the 220V power supply as shown in the figure, and turn on the switching power supply. After the welding machine is powered on, the cooling fan and the chiller will run automatically. If they are not running, check whether the emergency stop and the key switch are turned on.

The chiller level must be in the green area of the tank level indicator.

After adding water for the first time or renewing the water, the air in the pump needs to be exhausted. Operation method: slowly loosen the exhaust plug under the water inlet. Tighten it again when water flows out.

Antifreeze in winter: 1. When the new equipment is transported or not used for a long time, the water in the water tank should be drained through sewage. 2. If the ambient temperature at night is lower than 2°C, it is recommended that the customer do not stop the machine or add antifreeze to the car. When the average daily temperature is higher than 5°C, replace the water containing antifreeze with pure water.

Dustproof in summer: Clean the filter screen of the chiller in about a month in summer.

When the chiller is running normally, you can turn on the laser button, wait for a beep of the 5S laser, and then turn on the enable button. (Before use, make sure whether the emergency stop of the laser and the key switch are turned on)

Laser indicator light: ALARM green ACTIVE red POWER green is normal.

Before using the optical fiber hand-held welding machine, it is necessary to inject protective gas, and adjust the gas size according to the welding product.

Functional protection and features:

The signal status display on the page: Shutter Gas Welding Torch Status Conduction Status Laser Head Status

1. Optical shutter: control of the optical signal of the laser switch. (In normal use, turn on the light

The light-emitting signal of the shutter button takes effect, and the shutter button will be activated after 15 minutes of no operation.

automatic shutdown)

2. Gas: For gas control, percentage control is effective when a proportional valve is installed.

3. Welding torch status: refers to the light-emitting trigger button on the torch head, and the trigger button starts

when the light is on.

4. Conduction state: refers to the loop signal generated by the gun head touching the metal plate. (Gun

When the head touches the metal plate with alligator clip, the conduction signal light is on, this signal is the light protection

protection function, short circuit is prohibited)

5. Laser head status: refers to the status of the laser gun head motor. (The motor is powered on normally

This light is on during communication, and when the motor fails and does not work, the signal light is off and the liquid crystal of the gun head

The screen displays the E signal alarm, the light signal is locked and the trigger light button is invalid)

Control section in the page: Laser Control

Laser head control

gas control

1. Laser control:

1. Power: 0-100%

2. Frequency: 50-30000HZ

3. Duty cycle: 0-100%

Suggestion: The power selects the appropriate laser power according to different material thicknesses. The frequency is established

3000-5000HZ is recommended. Duty cycle: according to the requirements of welding penetration. When the thin plate does not penetrate the welding, the duty cycle can be appropriately reduced

2. Laser head control:

1. Patterns: Point, Line, Circle, Double O, Triangle

shape, figure 8 (3 new flare modes are added, there are 6 different flare shapes in total

state selection)

2. Frequency: refers to the motor speed (2-46HZms) adjustable, among which

1HZ=10 circle calculation.

3. Width: refers to the spot size, (0.2-5mm) adjustable.

Suggestion: Dot mode: refers to the state where the motor does not swing, and the light spot is the smallest. penetrate

Strong force, can be used for penetration welding, stitch welding, or thicker materials.

Linear mode: refers to swinging a motor to connect the points into a line, which can be adjusted

The width of the direction, the energy density is concentrated, it can have a certain penetrating power to the thick plate, and the Fillet welding is used for tailor welding.

Circular: 2 motors are oscillated, and the dots are edged into different light spot patterns, which can

Adjusting the diameter, the energy density is uniform, the advantages of thin plate welding are obvious, and the minimum 0.3mm sheet welding. It is used for tailor welding and internal fillet welding.

Double O, triangle, figure eight: two motors swing, the main function is The hollowness of the spot is reduced, the laser dispersion range is wider, and the sheet is radiated by light.

Larger and more even

3. Gas control: Gas advance and delay are recommended to be set at about 150ms.

Used to protect welding fumes from contaminating the protective lens. Proportional valve, when connected to proportional valve Gas Percentage control of gas availability.

Protective function:

1. Laser head protection: When the laser head has (E) signal or no data output,

The system detects the motor failure, the status light of the laser head goes out, and the system stops sending at the same time outgoing signal. The torch status can be lit, but the trigger is invalid.

2. On-state protection: The on-signal is controlled by an independent 24V voltage.

When the interference signal or non-own 24V voltage is reached, the state is off, and the system stops sending

Send out an optical signal. The torch status can be lit, but the trigger is invalid.

3. Welding torch state protection: when the welding torch receives the conduction state and the laser head state, all When normal, the trigger button can be pressed to emit light.

4. Trigger button protection: This button sets up multiple independent circuits, that is, in any If the protection function is disturbed or fails, releasing the trigger button can force the system to stop.

Stop the connection with the laser and effectively prevent the laser from being emitted.

5. System leakage protection: The motherboard adds multiple isolation protections to prevent chassis leakage.

Lightning and other factors burn out the motherboard or interfere with the motherboard.

6. Shell protection: The motherboard and driver are protected by a metal shell, which can better shield the outside world interference.

Red light offset settings:

1. Adjust the angle of the X, Y motor reflector, and change the offset position of the red light

2. The laser center point adjustment radius is 5mm

3. Make sure to check that all motor circuits are normal before adjustment to avoid wrong operation.

End User Software Lock Settings:

SN identification code: refers to the system administrator number, written by 8 digits (such as:

20200315)

Software Version: The software version number of the motherboard.

Use period: refers to the effective use time, when (-) appears, it is permanent use

use permissions.

Registration number: refers to the number that needs to be entered when unlocking.

Multi-language selection: 5 new language switching functions are added: Chinese, English,

Russian, Vietnamese, Korean

Brief introduction of structure and function of double swing hand-held welding head

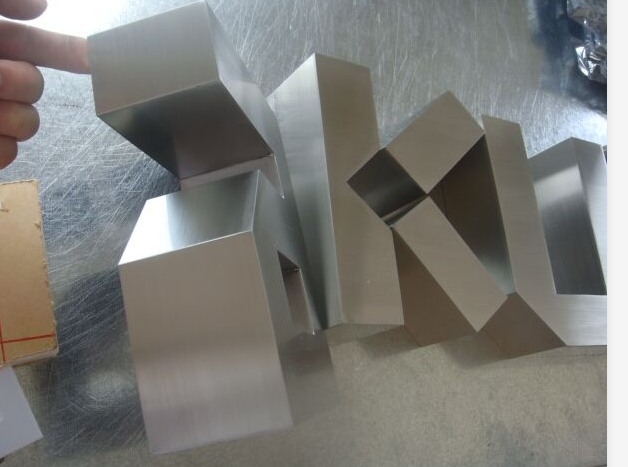

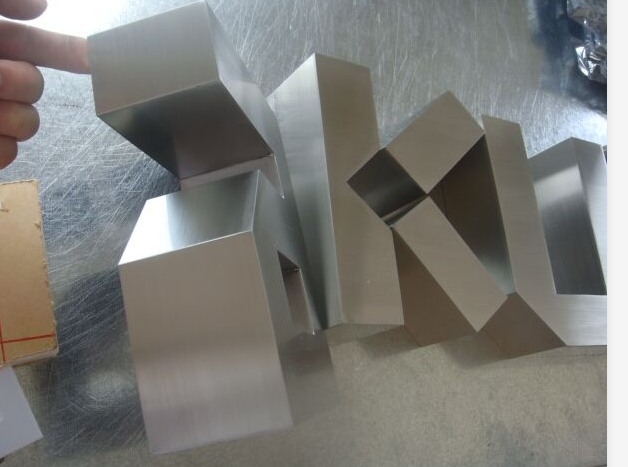

1. Copper nozzle: customers can replace the corresponding nozzle (inside corner) according to different welding processes

Copper nozzle, male angle copper nozzle, wire feeding copper nozzle)

2. Threaded steel pipe: Twist the threaded pipe to adjust the focal length, and the adjustable distance is ±

10mm

3. Trachea interface: protective gas blowing port

4. Conduction signal line: connected with the copper nozzle, touch the ground wire of the iron plate to generate a loop during welding.

full protection

5. Protective lens mounting port: Protective lens with water cooling structure to protect the service life of the lens

Longer lasting, it is recommended to wipe 1 time a day with an alcohol-free cotton swab to protect lens dust

6. Circulating water circuit: The cold water circulation structure is used to give the reflective lens and the internal structure of the gun body

cool down

7. Liquid crystal display: used to display the parameters set by the system and whether the motor signal is positive

often

8. Gun body handle: Alumina technology, lightweight and comfortable to hold

9. Light-emitting trigger button: after changing the handle structure and trigger button position, it can be applied to

Left-handed operation can solve the problem of inconvenient operation for left-handed people.

10. QBH locking sleeve: the connection end with the laser QBH, pay attention to cleaning when installing to avoid dust entering the gun body

Wire feeder structure and accessories:

1. Wire feeding fixture and wire feeding copper nozzle and welding copper nozzle and goggles

2 The internal structure of the wire feeder adopts high-precision fully enclosed low-speed motor, double drive

The moving wire feeding structure makes the wire feeding smoother and stronger without jamming, and it can be dragged.

Wheels for easy movement at any time

3 Enclosed chassis design with removable handle, Chinese red paint finish

4 wire feed regulator, LED screen displays real-time wire feed speed, high-precision speed regulation

Knob, wire feed speed adjustable range is higher

Problems and Troubleshooting

1. The status of the laser head is not displayed: the X.Y motor cable may be loose, or the 15V power supply

Input is interrupted, or the motor is damaged

2. There is no conduction status display or the light is intermittent during the welding process: it may be conduction

The signal is not connected or the wire is loose and not plugged in tightly, the alligator clip is not formed with the DT1 signal

loop. Intermittent light emission may be because the copper nozzle is loose or the plate is rusted during the welding process, and it is not connected to the clip.

3. The status of the welding torch is not displayed: it may be that the switch button of the welding torch head is loose. The terminal port has fallen off

4. The gas cannot be controlled; the gas button on the touch screen is not turned off or the gas delay is set

High, or the positive and negative poles of the valve are reversed

5. The parameters of the LCD screen of the handheld head are not synchronized with the setting parameters of the touch screen: the system 24V power supply

The electrical input and the galvanometer 15V power supply input cannot be powered on at the same time, resulting in asynchronous parameters and data cannot be updated

6. It is easy to burn the protective lens: the gas is impure or no air pressure, the sealing ring is damaged,

Focus position deviation, waterway damage and other factors. During welding, the gas starts and builds up

Beam delay is set around 150ms

7. The welding torch head is overheated: the protection lens is burnt or the circulating water circuit of the chiller is not connected or the laser

The fiber diameter of the device is too large.