160 Tons of Bending Force: The machine delivers a robust 160-ton bending capacity, making it suitable for handling a wide range of sheet metal thicknesses, from thin sheets to thicker materials.

3200mm Bending Length: With a bending length of 3200mm, this press brake can accommodate larger sheet metal pieces, making it ideal for industries that require bending of long workpieces.

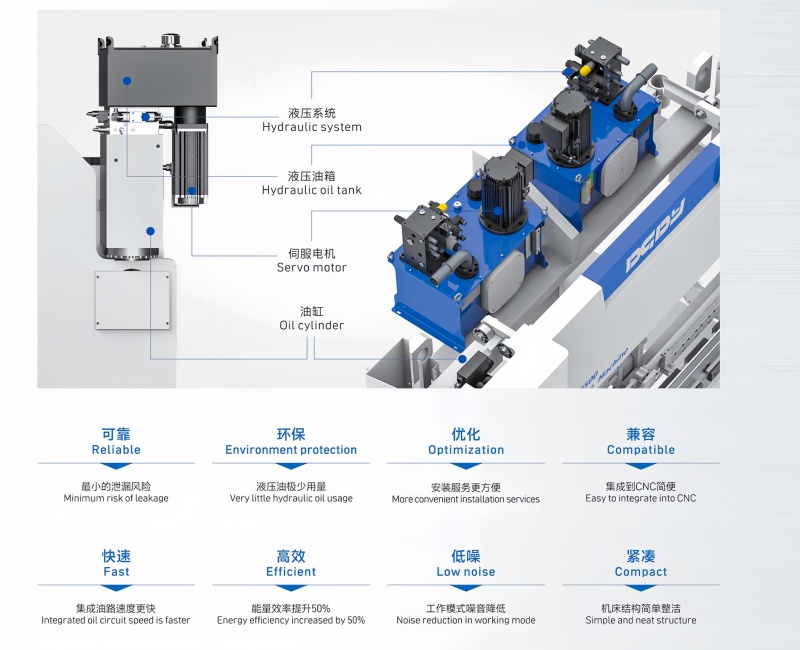

CNC Control System: The CNC electro-hydraulic control system provides precise control over the bending process, ensuring accuracy and repeatability. It allows for quick adjustments and seamless operation, reducing setup times and improving overall productivity.

Servo Hydraulic System: The incorporation of servo motors significantly enhances energy efficiency by adjusting the hydraulic pressure dynamically. This results in reduced energy consumption and operational costs compared to traditional hydraulic systems.

Oil-Electro Hybrid Technology: This technology optimizes both hydraulic and electrical systems, combining the advantages of both. The oil-electric hybrid drive reduces energy consumption and improves system reliability.

Precision Bending: Equipped with advanced backgauge systems, die setups, and ram positioning technology, the machine ensures highly accurate bending, even for complex shapes and tight tolerances.

Advanced Safety Features: The machine is designed with safety in mind, featuring automatic safety systems, light curtains, and emergency stop buttons, ensuring safe operation for the operator.

High Productivity: With adjustable working speeds, rapid return strokes, and minimal downtime between bends, the machine maximizes throughput while maintaining high-quality results.