Introduction to the 2000KG Vacuum Lifting Devices for Lifting and Transporting Glass, Granite, Stone, Concrete, and Sheet Metal Plates (6000x2000mm) – Plug-in AC220/380V

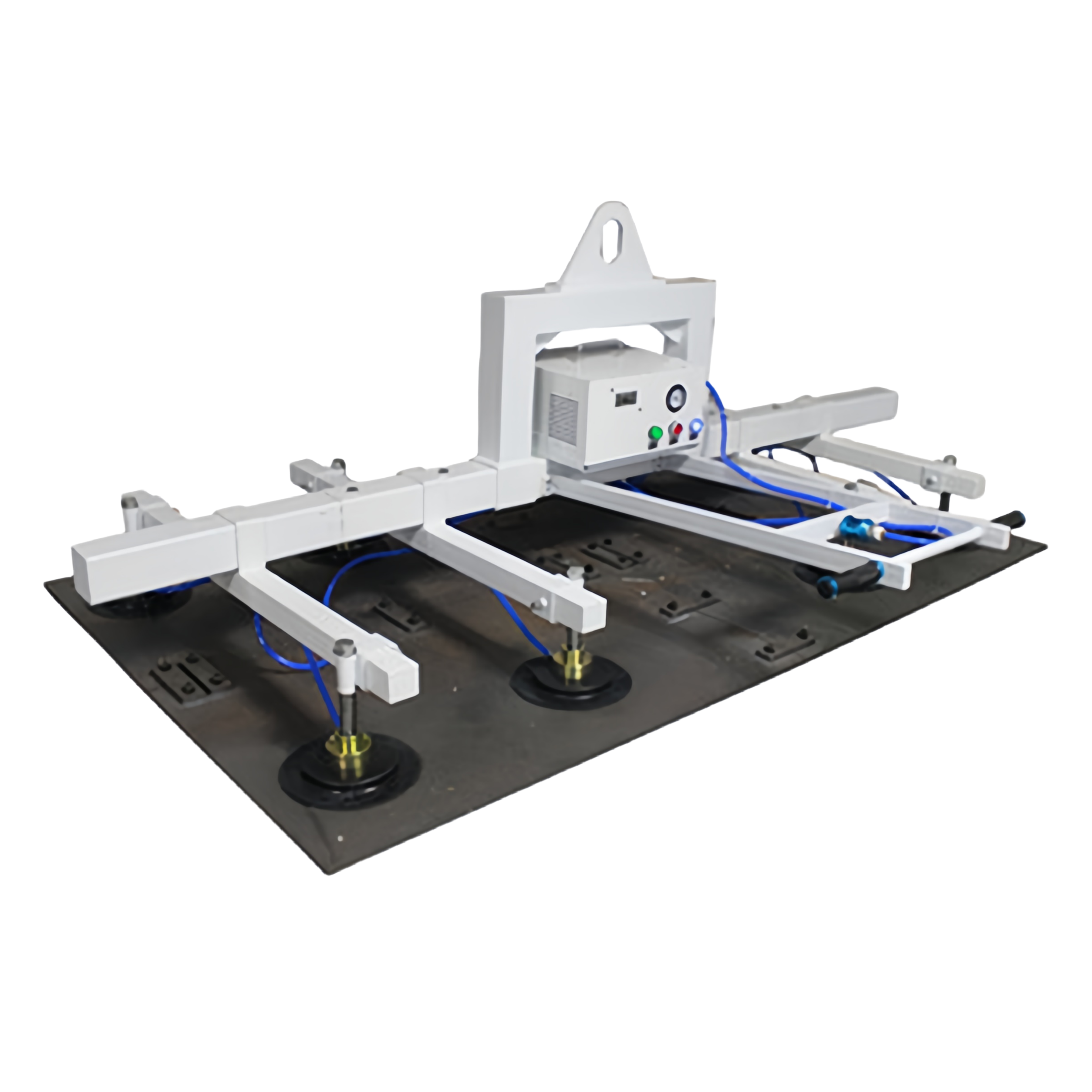

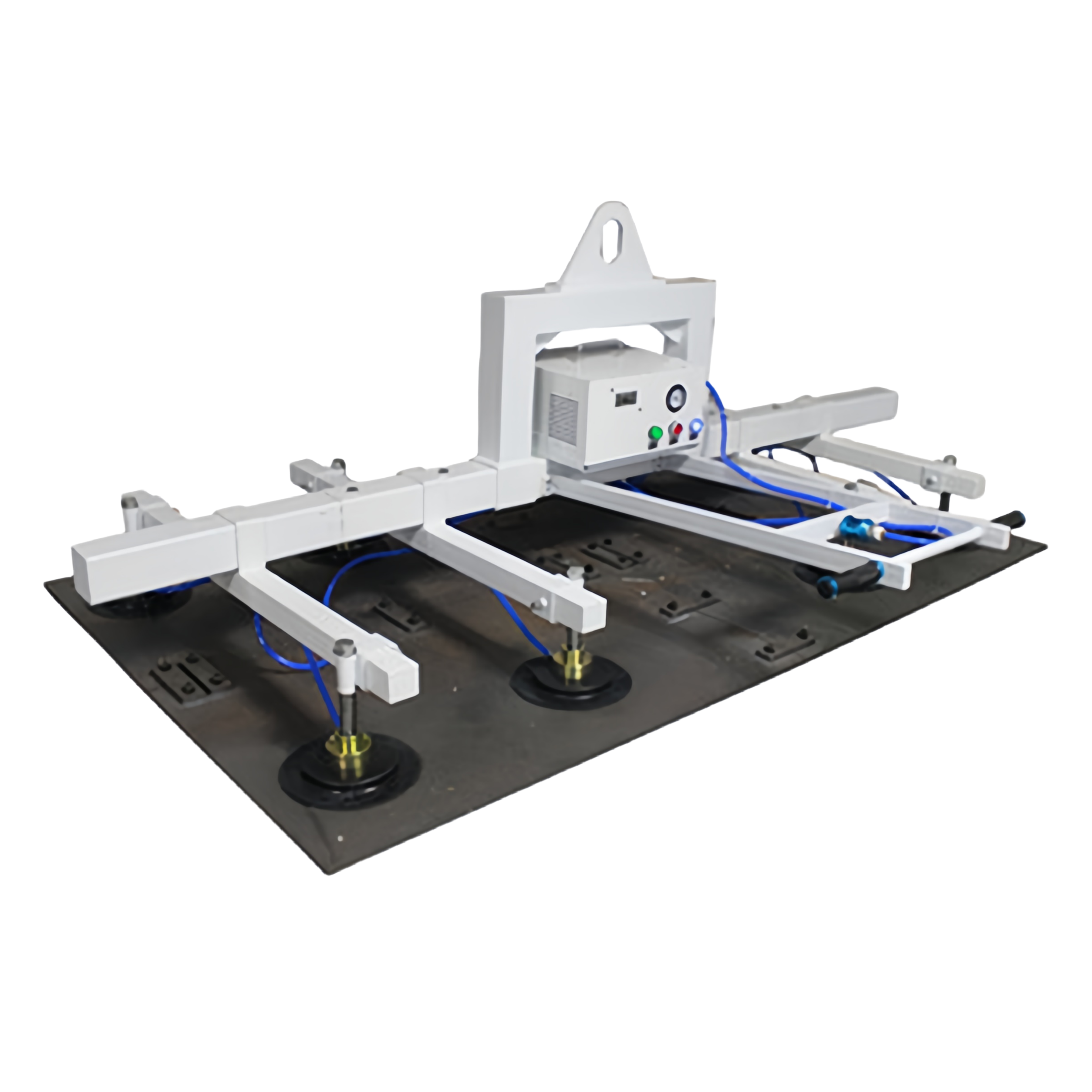

The 2000KG Vacuum Lifting Devices are state-of-the-art material handling equipment designed for lifting and transporting a wide range of heavy materials, including glass, granite, stone, concrete, and sheet metal plates up to 6000x2000mm in size. These lifting systems are powered by AC220/380V, providing robust, reliable, and energy-efficient operation for industries that require heavy-duty lifting and transportation of large-format materials.

With a lifting capacity of up to 2000kg, these vacuum lifting devices offer exceptional versatility and efficiency in handling large, bulky, and fragile materials. They are perfect for industries such as construction, glass manufacturing, stone processing, metal fabrication, and other sectors that deal with heavy and oversized materials on a daily basis.

This vacuum lifting system combines advanced vacuum technology, a powerful suction system, and ergonomic design to ensure safe, fast, and efficient handling of materials while reducing risks of injury and damage. Whether you're handling glass panels for architectural installations, granite slabs for countertops, stone tiles for construction, or sheet metal plates for fabrication, this vacuum lifter provides a reliable, flexible, and high-performance solution.

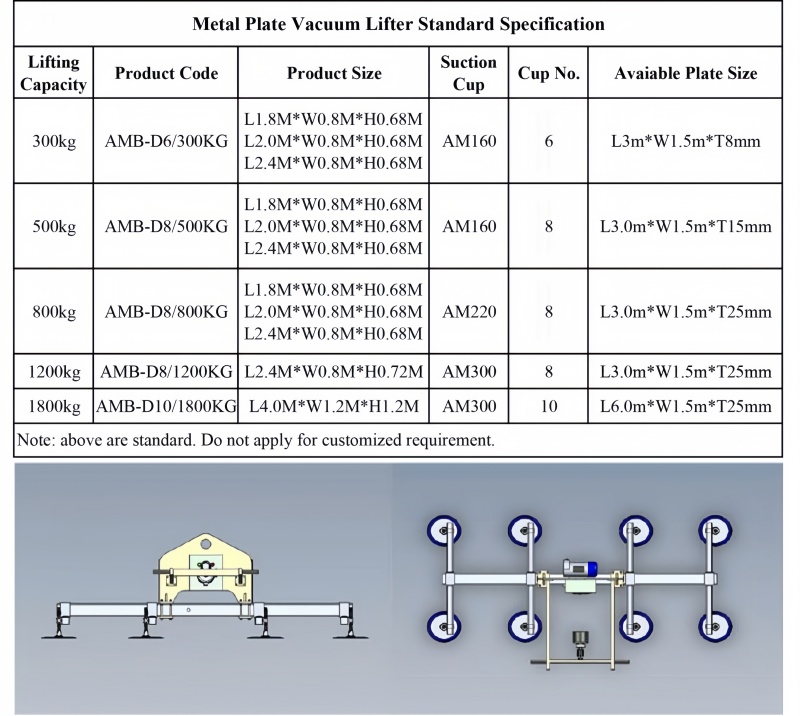

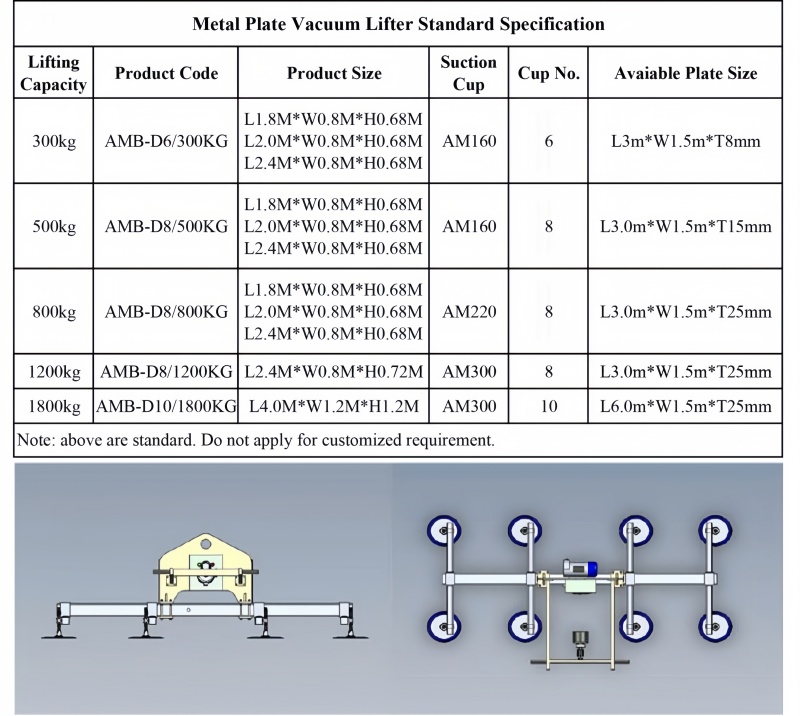

| Product Type | Rechargeable Lifter | Plug-in Lifter |

| Model | JS-J1000-5M | JS-J2000-5M | JS-C1000-25M | JS-C2000-5M |

| Rated Load (kg) | 1000 | 2000 | 1000 | 2000 |

| Suction Cup Diameter (mm) | 200 | 200 | 200 | 200 |

| Number of Suction Cups | 12 | 12 | 12 | 12 |

| Dimensions (mm) | 5000*1000 | 5000*1000 | 5000*1000 | 5000*1000 |

| Plate Size (mm) | 6000*2000 | 6000*2000 | 6000*2000 | 6000*2000 |

| Operating Power (V) | DC12V | DC12V | AC220V/380V | AC220V/380V |

Key Features of the 2000KG Vacuum Lifting Device

1. High Lifting Capacity (Up to 2000kg)

The 2000KG vacuum lifting device is engineered to handle materials weighing up to 2000kg (approximately 2 tons), making it suitable for lifting large-format materials such as glass panels, granite slabs, stone tiles, and sheet metal plates. This high lifting capacity enables the lifter to handle oversized sheets and panels with ease, without requiring additional equipment or manual labor.

Heavy-duty Construction: The vacuum lifter’s components are made from high-strength materials that are designed to withstand the heavy lifting requirements of industrial environments. Whether lifting a granite slab or a concrete panel, this lifter ensures maximum reliability and durability.

Large-Scale Applications: With the ability to lift large materials of up to 6000x2000mm, this vacuum lifter is ideal for industries where oversized materials are frequently used.

2. Advanced Vacuum Suction System

At the core of the 2000KG vacuum lifting device is its advanced vacuum suction system, which ensures a firm and secure grip on materials, even when lifting large and heavy sheets. The powerful suction pads are capable of lifting a variety of materials, including glass, stone, granite, and metal plates, without the risk of slipping or detachment.

High Suction Power: The vacuum pump generates strong suction, ensuring that the lifter securely holds onto materials weighing up to 2000kg.

Adjustable Suction Pads: The suction pads are adjustable and designed to accommodate different material types and sizes. The lifter can be customized with multiple suction cups for materials with varying surface areas and characteristics.

Safe Material Handling: The vacuum suction method ensures that sensitive materials like glass are not damaged during lifting. It helps prevent scratching, chipping, or cracking, which can occur with traditional lifting methods.

3. AC220/380V Power Supply

The AC220/380V power supply provides the necessary power to operate the vacuum lifter efficiently in industrial settings. This high-voltage system ensures that the lifter can perform high-load lifting tasks continuously, making it suitable for large-scale operations, such as stone processing, metal fabrication, or construction.

Reliable Power Supply: The plug-in power design ensures uninterrupted operation, especially in environments where there is a consistent power source.

Energy-Efficient Operation: While the lifter uses AC220/380V for power, it is designed to be energy-efficient, minimizing electricity usage while still providing maximum lifting power.

4. Large Material Handling Capacity

One of the standout features of this vacuum lifter is its ability to handle materials with large dimensions (up to 6000x2000mm). This makes it ideal for industries that frequently work with oversized materials, such as construction, glass installation, and metal fabrication.

Oversized Material Handling: The lifter can handle large panels and sheets, including granite, stone, concrete, and sheet metal. This is particularly useful for applications where handling large-format materials is a common task.

Increased Efficiency: The ability to lift large sheets with a single device reduces the need for multiple lifting tools or cranes, streamlining operations and improving efficiency on the job site.

5. Ergonomic and Safe Design

The ergonomic design of the vacuum lifting device ensures that operators can lift heavy materials with minimal physical strain. By reducing the need for manual labor, the vacuum lifter enhances worker safety and productivity.

User-Friendly Controls: The device is equipped with intuitive, easy-to-use controls that allow the operator to raise, lower, and transport materials safely and efficiently.

Reduced Risk of Injury: With vacuum lifting technology, the lifter minimizes the risk of workplace injuries caused by the manual handling of heavy or awkward materials. This is especially important when working with fragile materials like glass or large, unwieldy stone or concrete panels.

Improved Workplace Safety: The lifter is designed with safety in mind. Features like automatic vacuum pressure monitoring, emergency stop functions, and locking suction pads ensure that the material is securely held throughout the lifting and transportation process.

6. Durability and Low Maintenance

This vacuum lifting device is built to withstand the demanding conditions of industrial environments. With its high-strength materials, reliable vacuum pump, and low-maintenance design, the lifter offers long-lasting performance with minimal downtime.

Heavy-Duty Components: The lifter’s frame and suction system are built to handle the stresses of lifting heavy, large-format materials. It can endure harsh operating conditions and constant use without significant wear and tear.

Minimal Maintenance: The vacuum lifter requires minimal maintenance, and its durable design means that it will operate efficiently with regular upkeep. Maintenance tasks include checking the vacuum pressure, inspecting the suction cups, and ensuring the battery is charged (if applicable).

7. Wide Range of Applications

This vacuum lifting device is suitable for various applications across multiple industries that involve the handling of large, heavy materials. Some of the key applications include:

Glass Handling: Ideal for lifting and transporting glass panels for building facades, windows, or glass doors. The vacuum lifter ensures safe lifting and prevents damage to delicate surfaces.

Stone and Granite Handling: Used in stone processing plants and granite fabrication workshops, this device can lift heavy stone slabs and granite countertops without causing damage or surface defects.

Concrete Handling: Ideal for moving heavy concrete panels, pre-cast blocks, and other construction materials, especially when working with large, oversized elements.

Metal Plate Lifting: In metal fabrication and manufacturing, the lifter is useful for handling large metal plates or sheets during processes such as cutting, welding, or assembly.

Construction and Installation: This vacuum lifter is essential for moving and placing large components during building projects, industrial installations, or prefabricated construction.

8. Safety Features

Safety is a top priority when handling heavy, large-format materials, and this vacuum lifting device is designed with multiple safety features to protect both operators and materials.

Vacuum Pressure Monitoring: The system includes automatic vacuum pressure monitoring, which ensures that the vacuum levels remain within a safe range during lifting. If the vacuum pressure drops too low, the system will alert the operator to address the issue.

Emergency Stop Button: In case of malfunction or emergency, the lifter is equipped with an emergency stop button that instantly halts all functions, providing quick response in critical situations.

Locking Mechanism: Once the material is lifted, the suction pads lock into place, providing added security during transport and reducing the risk of the material slipping or detaching during movement.

9. Cost-Effective and Energy-Efficient

With AC220/380V power supply and minimal maintenance requirements, this vacuum lifter is an affordable solution for industries that need to handle heavy materials. It reduces the reliance on cranes, forklifts, or other large machinery, offering a more cost-effective and efficient solution for material handling tasks.

Reduced Labor Costs: The lifter reduces the need for manual labor, helping businesses save on labor costs while improving efficiency.

Lower Energy Consumption: The vacuum lifter is designed to operate with minimal energy consumption, ensuring cost-effective operations and sustainability.