12-axis 2500mm CNC Sheet Metal Folding Machine is a highly sophisticated tool designed for precision metal fabrication. With its advanced features and capabilities, it is well-suited for various applications in the manufacturing sector.

Key Features

Bending Capacity

Bending Length: Designed for metal sheets up to 2500mm in length, making it ideal for medium-sized workpieces.

Material Thickness: Capable of bending a range of thicknesses, typically from 0.5mm to 10mm, depending on the material type and specific machine configuration.

12-Axis Control

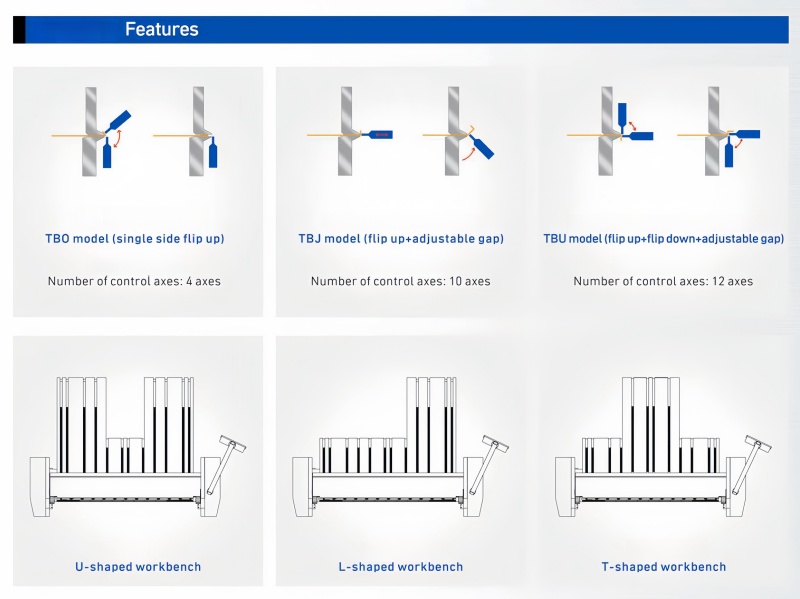

Multi-Axis Bending: The machine features 12 axes of movement, allowing for complex and intricate bending operations. This enables the creation of various shapes and geometries in a single setup, reducing the need for multiple processes.

Servo Drives: Each axis is controlled by servo motors, ensuring high precision and repeatability in bending operations.

Advanced Tooling

Folding Tools: Equipped with a range of folding tools, including sharpnose and segmented tools, to accommodate different bending requirements and angles.

Automatic Tool Change: Some models may include an automatic tool-changing feature for enhanced productivity and reduced downtime.

Control System

CNC Control: The machine is equipped with a user-friendly CNC control system, typically featuring a touchscreen interface that allows operators to easily program and modify bending operations.

Graphic Display: Advanced software may provide 2D/3D graphical representation of bending sequences, making it easier to visualize the final product.

Backgauge System

Safety Features

Light Barriers: Integrated safety systems, such as front light barriers, to ensure operator safety during operation.

Emergency Stop: Easily accessible emergency stop buttons for immediate shutdown in case of an emergency.

Applications

General Metal Fabrication: Suitable for producing a wide range of components, including brackets, enclosures, and frames.

Automotive Industry: Ideal for manufacturing parts like chassis components, brackets, and body panels.

HVAC Systems: Used for creating ductwork and fittings with precise bends.

Aerospace: Capable of producing high-precision components with stringent quality standards.

Benefits

Increased Efficiency: The 12-axis control and automation features significantly reduce setup times and improve cycle times, leading to higher production throughput.

Enhanced Accuracy: The precision of CNC bending minimizes material waste and ensures consistent quality in the finished parts.

Flexibility: The ability to quickly change tools and adjust parameters allows for handling a variety of projects without extensive downtime.

Applications

This type of CNC folding machine is commonly used in industries such as:

Automotive: For producing parts like brackets, frames, and enclosures.

Aerospace: Manufacturing components that require high precision and quality.

HVAC: Creating ductwork and other components.

Metal Fabrication Shops: General-purpose bending and folding for custom projects.

Electronics: Producing enclosures and mounts for electronic devices.

Recommended Brands

When considering a 10-axis, 2500mm CNC sheet metal folding machine, look for reputable manufacturers such as:

Amada

Trumpf

Bystronic

EHT

LVD

Technical Parameter

| Item | Unit | TB025 | TB032 | TB041 | TBJ25 | TBJ32 | TBJ41 | TBU25 | TBU32 | TBU41 |

| Bending thickness (carbon steel) | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Bending thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending angle range | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | -45...+45 | -45...+45 | -45...+45 |

| Max. bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Rear positioning length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Open height | mm | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Bending tool height | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| Control axis number |

| 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Pressing speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Bending speed | m/s | 5.0 | 5.0 | 5.0 | 6.5 | 6.5 | 6.5 | 7.0 | 7.0 | 7.0 |

| Motor energy consumption | kW | 3.5 | 4.5 | 6.1 | 3.5 | 4.5 | 6.1 | 5.5 | 7.0 | 10.0 |

| External dimensions (L × W × H) | mm | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5700×2150 |

| Weight | kg | 4500 | 5300 | 7500 | 4500 | 5300 | 7500 | 4900 | 7000 | 11000 |

This table provides information on various models of CNC sheet metal folding machines, highlighting their specifications such as bending thickness, bending angle range, maximum bending length, open height, speed, motor energy consumption, dimensions, and weight.

Recommended Models:

Some well-regarded brands that manufacture high-quality CNC sheet metal folding machines include:

Amada: Known for advanced technology and high-quality machines suitable for various bending applications.

Trumpf: Offers innovative solutions and robust machines for efficient sheet metal processing.

Bystronic: Features user-friendly interfaces and reliable performance for bending and folding tasks.

EHT: Provides a range of CNC folding machines with customizable features to meet specific production needs.

Applications:

CNC folding machines are widely used in industries such as:

Automotive manufacturing

Aerospace components

HVAC systems

Electrical enclosures

Furniture manufacturing