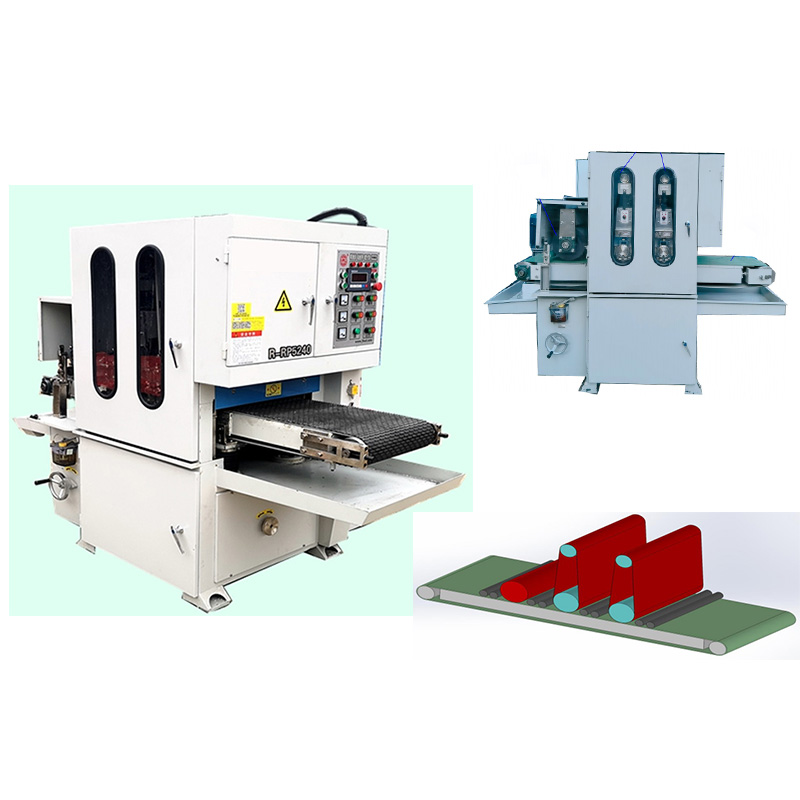

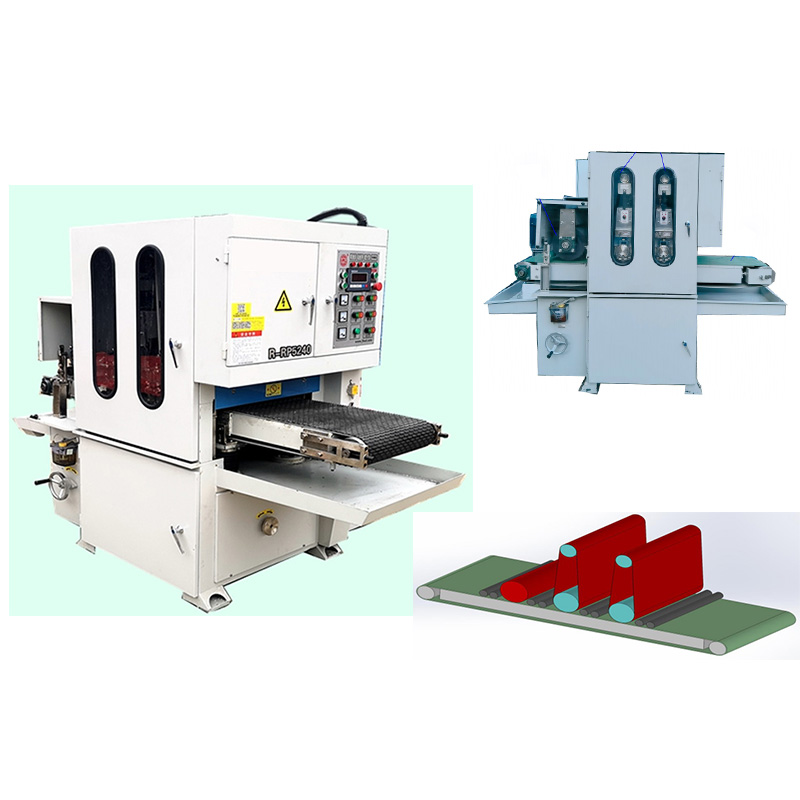

400mm Wet Type Wide Belt Sander Line Graining/Deburring/Finishing Machine

The 400mm Wet Type Wide Belt Sander is a state-of-the-art industrial machine designed for the precise and efficient line graining, deburring, and surface finishing of metal components. Perfect for industries that require high-quality, consistent surface treatments such as automotive manufacturing, metal fabrication, and stainless steel processing, this machine combines advanced technology with robust construction to meet the demands of modern metalworking.

This machine is specifically engineered for use with metals such as steel, aluminum, stainless steel, copper, and more, ensuring optimal results in various applications, including deburring, oxide removal, and the creation of a polished surface finish.

1. High-Efficiency Wet Sanding Process

The wet sanding system is a critical feature of this machine, offering multiple benefits over dry sanding methods. The use of water or a special coolant during the sanding process provides superior cooling, reduces friction, and eliminates dust production. This results in:

Extended Belt Life: The wet sanding system reduces wear and tear on abrasive belts, which enhances the longevity of the consumables and lowers maintenance costs.

Cleaner Work Environment: The absence of dust significantly improves operator health and safety, creating a cleaner and more productive work environment.

Enhanced Surface Finish: The wet process helps to achieve smoother, more consistent finishes by controlling heat buildup and minimizing abrasive wear.

2. Versatility for Multiple Applications

This 400mm Wet Type Wide Belt Sander is not just a deburring machine but also highly effective in line graining and surface finishing. It is designed to handle various metal types and achieve different levels of surface roughness, which makes it suitable for several applications, including:

Deburring: Removes burrs and sharp edges created during the metal cutting process, ensuring parts are safe to handle and are visually appealing.

Line Graining: Creates uniform, parallel lines on the metal surface, which is ideal for aesthetic purposes and specific finishing requirements.

Surface Finishing: The machine provides a polished, clean surface finish for metal parts, which enhances their appearance and improves their resistance to corrosion.

Oxide and Scale Removal: Effectively removes oxidation or scale from metal surfaces, preparing parts for further treatments like coating or painting.

3. Precision and Consistency

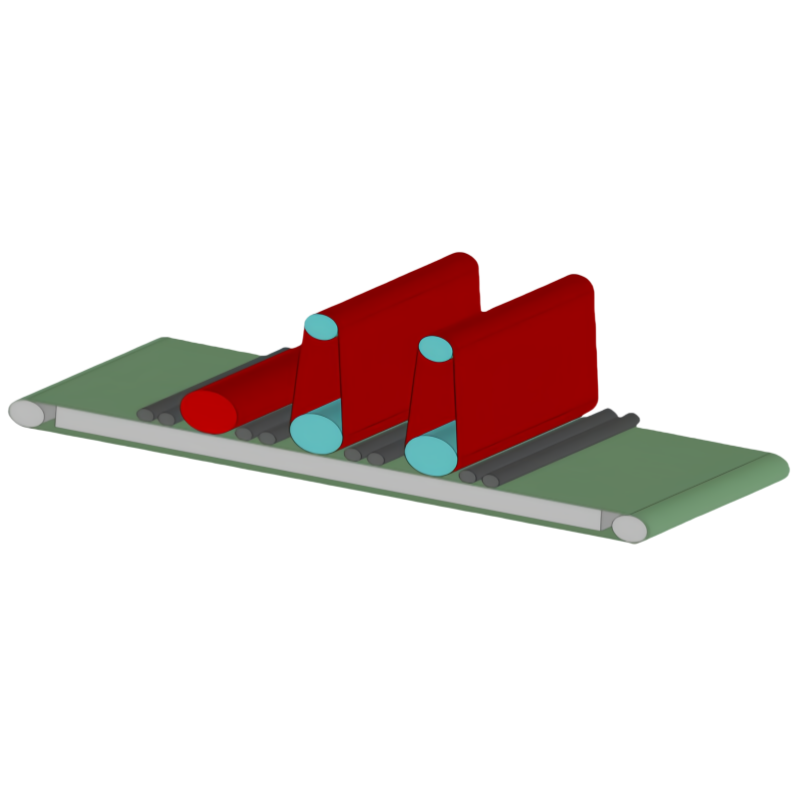

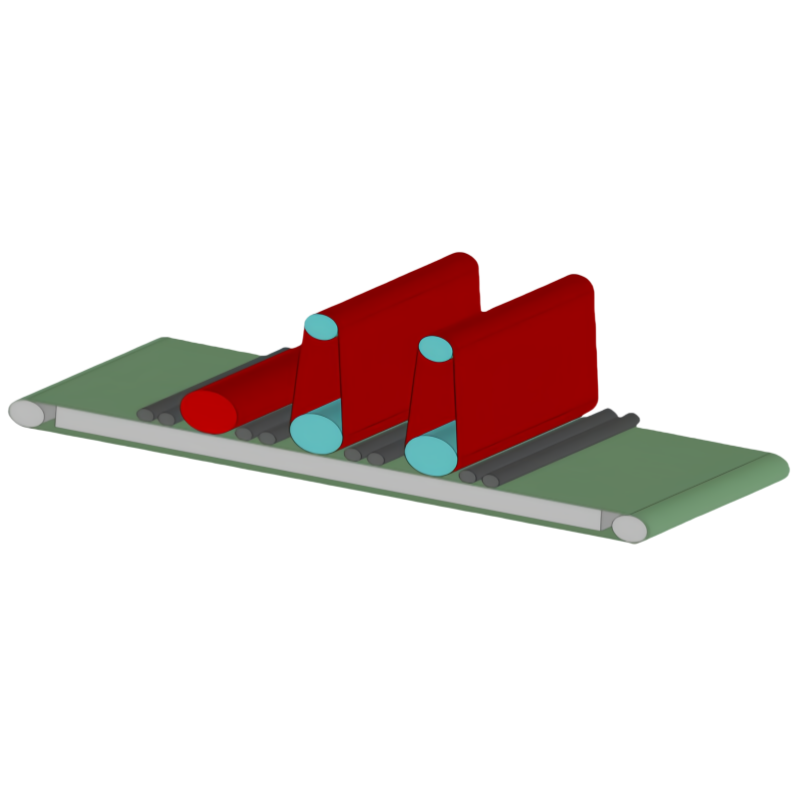

At the core of the 400mm Wet Type Wide Belt Sander is its precise sanding mechanism, which provides consistent results across all workpieces. The machine is designed for uniform pressure distribution, ensuring that the sanding process is consistent from one end of the workpiece to the other. This is particularly important for industries where dimensional consistency and surface quality are critical.

Precision Feed System: The adjustable conveyor feed ensures that workpieces pass through the sanding section at a consistent speed, improving the accuracy of the surface treatment.

Automatic Pressure Adjustment: The machine features an automated pressure adjustment system that ensures uniform sanding pressure, which is essential for achieving a uniform finish across different materials and thicknesses.

4. Robust Construction for Heavy-Duty Operation

This wide belt sander is built to last, featuring a heavy-duty frame that ensures the machine can withstand the rigorous demands of industrial environments. The robust design of the machine guarantees high performance and reliability, even under continuous operation.

Durable Components: The use of high-quality materials for the construction of the frame and components ensures the longevity of the machine, even in high-throughput environments.

Low Vibration Operation: The machine is engineered to minimize vibrations, which helps to maintain the precision of the sanding process and improves the quality of the finish.

5. User-Friendly Interface

The user interface of the 400mm Wet Type Wide Belt Sander is designed for ease of use, with a digital control panel that allows operators to easily adjust machine settings. The intuitive controls make it simple to modify sanding speeds, belt pressure, and feed rates according to specific requirements.

Easy Belt Change: Changing the sanding belt is quick and simple, reducing downtime and improving operational efficiency.

Adjustable Settings: Users can easily adjust the feed speed, sanding pressure, and belt tension to achieve the desired finish on various materials.

6. Integrated Dust and Sludge Extraction System

As part of its wet sanding process, the machine is equipped with an integrated vacuum system that removes excess water, dust, and metal particles from the sanding process. The dust extraction system helps to maintain a clean workspace, reducing health risks and ensuring the machine operates efficiently.

Water Recovery System: The system recycles water used in the wet sanding process, reducing waste and ensuring that water usage is kept to a minimum.

Efficient Filtration: The sludge and water filtration system ensures that the coolant is filtered and reused, improving the overall efficiency of the machine.

7. Customizable Options

This machine offers a variety of customization options to suit the specific needs of different industries and applications. These include:

Belt Size Options: While the standard version of the machine features a 400mm wide belt, other sizes can be accommodated for different material processing requirements.

Additional Heads: Depending on the requirements of the project, additional sanding heads or polishing heads can be added to the machine for more complex finishing tasks.

Special Abrasive Belts: Depending on the desired surface finish, users can select from a wide range of abrasive belts, from coarse to fine, for specific metal finishing tasks.

Wet Belt Sander:

| Specification | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm |

| Max Working Height | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| Min Working Length | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| First Abrasive Belt Power | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW |

| Second Abrasive Belt Power | - | 5.5 kW | - | 5.5 kW | 5.5 kW | 5.5 kW |

| Third Abrasive Belt Power | - | - | - | 5.5 kW | - | 5.5 kW |

| Polishing Wheel Power | - | - | - | - | 5.5 kW | 5.5 kW |

| Rotating Motor Power | - | - | - | - | - | - |

| Feed Motor Power | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Lift Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW |

| Swing Motor Power | - | - | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Vacuum Motor Power | - | - | - | - | - | - |

| Machine Dimensions (L×W×H) | 1.8×1.5×1.8 m | 2.1×1.5×1.8 m | 2.1×1.5×1.8 m | 2.4×1.5×1.8 m | 2.4×1.5×1.8 m | 2.7×1.5×1.8 m |

| Machine Weight | 1000 kg | 1200 kg | 1200 kg | 1500 kg | 1500 kg | 1800 kg |

| Abrasive Belt Size | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm |

Applications

The 400mm Wet Type Wide Belt Sander is highly versatile and can be used in various industries for a broad range of applications:

Automotive Manufacturing: Surface finishing of automotive parts, including body panels, engine components, and other precision parts.

Metal Fabrication: Ideal for deburring, polishing, and grinding metal parts used in machinery and equipment.

Stainless Steel Processing: Used for polishing stainless steel surfaces, removing oxide layers, and creating consistent surface textures.

Industrial Metal Parts: Great for deburring, cleaning, and finishing industrial metal components used in construction, aerospace, and heavy machinery.

Conclusion

The 400mm Wet Type Wide Belt Sander is an essential tool for manufacturers in need of high-quality metal finishing. Whether it's deburring, line graining, surface polishing, or oxide removal, this machine delivers superior results with its advanced technology and robust design. Its efficient wet sanding process, customizable features, and user-friendly operation make it an excellent choice for industries that require precision, consistency, and reliability in their metal finishing processes.

By choosing the 400mm Wet Type Wide Belt Sander, companies can achieve enhanced production efficiency, reduce operational costs, and maintain superior product quality, making it a valuable investment for any industrial operation.