AC220V/380V Electric Vacuum Lifter for 800kg Sheet Metal Lifting

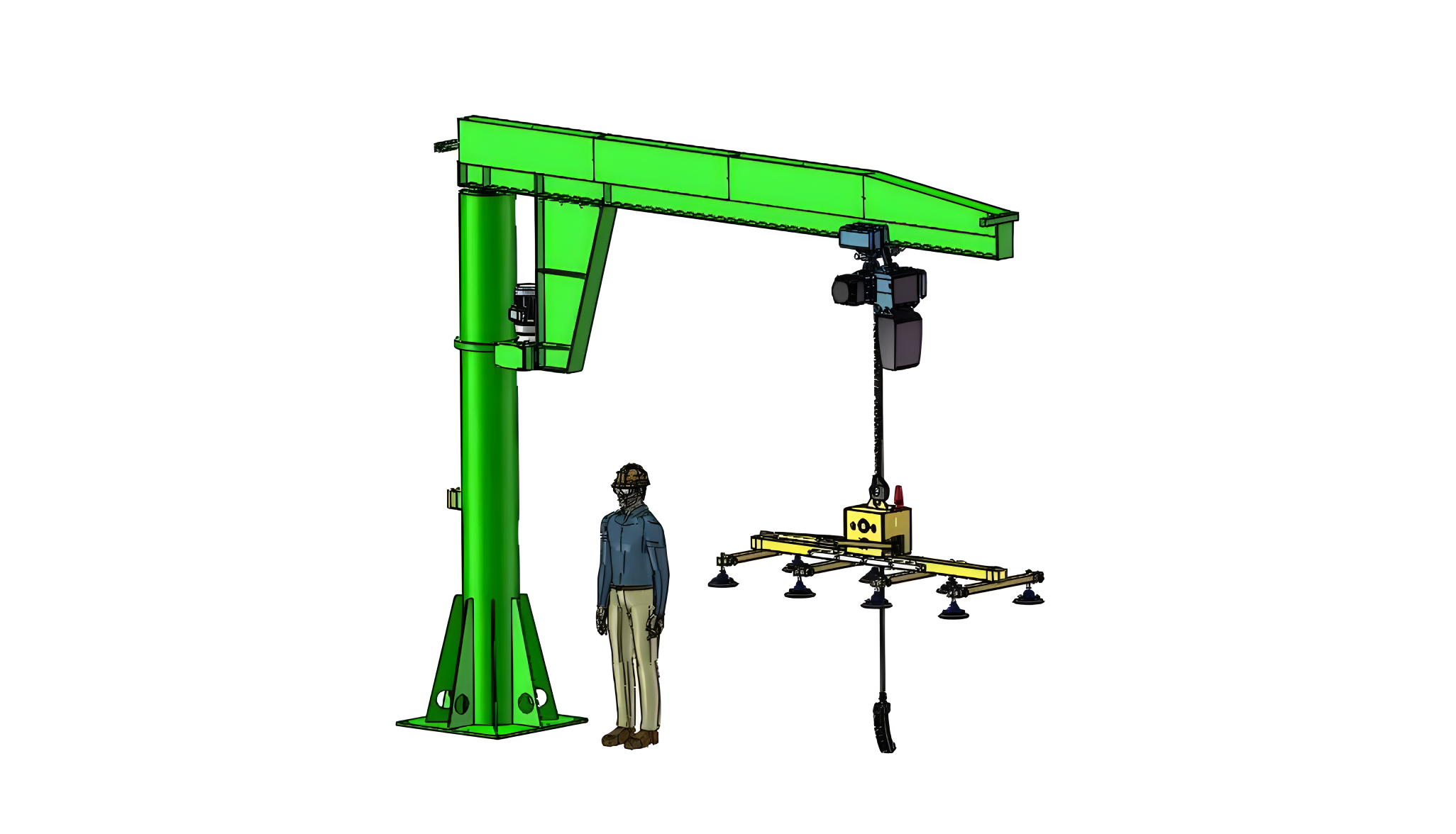

The AC220V/380V Electric Vacuum Lifter for 800kg Sheet Metal Lifting is a high-capacity, efficient, and safe lifting solution designed to handle and transport large, heavy sheet metal plates weighing up to 800kg. Utilizing electric vacuum technology, this lifter is ideal for industrial environments such as metal fabrication, manufacturing, and construction, where heavy, large sheet metal components need to be lifted, moved, and positioned with precision.

Key Features:

Heavy-Duty Lifting Capacity:

Capable of lifting sheet metal plates weighing up to 800kg.

Designed to handle large, heavy-duty metal sheets, making it ideal for industries requiring frequent handling of metal plates or panels.

Voltage Options (220V and 380V):

AC220V and AC380V models available to cater to different industrial power supply requirements.

The 220V version is perfect for standard power supply environments, while the 380V model delivers more power for large-scale, high-demand applications.

Electric Vacuum Pump:

Powered by a high-performance electric vacuum pump, this system generates powerful and consistent suction to securely lift sheet metal plates.

Reliable vacuum suction ensures the safety and stability of the metal sheets during lifting and transportation, reducing the risk of accidents or damage.

The electric vacuum pump is more energy-efficient and precise compared to traditional pneumatic or hydraulic systems, ensuring smooth operation.

Strong Vacuum Cups:

Customizable vacuum cups designed to securely grip various sizes and types of sheet metal.

The vacuum cups can be adjusted to accommodate different plate thicknesses and sizes, ensuring an optimal grip and reducing the risk of slippage.

Specially designed to minimize surface damage, preventing scratches or dents on sensitive metal surfaces.

User-Friendly Control System:

Simple control panel for easy operation, featuring intuitive buttons for controlling suction, lifting, and movement.

Includes functions for tilting, rotation, and precise positioning, allowing operators to handle sheet metal with great control and efficiency.

Ergonomic design reduces operator fatigue and increases productivity during repetitive lifting tasks.

Robust Construction:

Constructed from high-strength, durable materials, the vacuum lifter is built to withstand demanding industrial environments.

Capable of enduring heavy-duty lifting tasks without compromising on performance, ensuring long-lasting operation.

Safety Features:

Features vacuum monitoring sensors that alert operators if suction levels drop, ensuring a continuous secure hold on the lifted material.

Includes emergency stop buttons and overload protection to prevent accidents and ensure safe lifting practices.

Fail-safe mechanisms protect against vacuum loss, preventing accidental drops of the lifted sheet metal.

Enhanced Maneuverability:

The vacuum lifter is designed for easy maneuverability, allowing operators to move large, heavy metal sheets with minimal effort.

Precise positioning capabilities make it ideal for handling materials in tight spaces or when accuracy is crucial for further processing.

Energy Efficient:

Electric operation ensures reduced energy consumption and lower operational costs compared to pneumatic or hydraulic lifters.

The system is designed to be cost-effective and easy to maintain, minimizing downtime and maximizing productivity.

Applications:

Metal Fabrication: Ideal for lifting and moving large sheet metal plates in metalworking or fabrication shops.

Manufacturing: Suitable for transporting heavy metal panels, plates, and sheets during production or assembly.

Construction: Perfect for handling metal components in construction sites, particularly for handling steel plates used in building frameworks and structures.

Warehousing and Distribution: Facilitates the efficient handling of large sheet metal in warehouses, distribution centers, and during loading/unloading processes.

Safety and Maintenance:

Vacuum Monitoring: Continuous monitoring ensures that the suction level remains stable throughout the lifting process. The system will notify the operator of any drop in vacuum.

Low Maintenance: The electric vacuum lifter has fewer parts requiring maintenance compared to pneumatic or hydraulic systems, reducing downtime and overall maintenance costs.

Safety Alerts: Emergency stop features and overload protection systems help prevent damage to the lifter or materials.

Vacuum Lifter

| Product Model | JS-CG300-2M/3M | JS-CG600-2M/3M | JS-CG800-2M/3M |

| Rated Load (kg) | 300 | 600

| 800 |

| Suction Cup Diameter (mm) | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 6 | 8 |

| Outer Dimensions (mm) | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 |

| Plate Dimensions (mm) | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 |

| Working Voltage | AC220V/380V | AC220V/380V | AC220V/380V |

Typical Equipment Applications:

Sheet Metal Processing Industry: Primarily used for loading and unloading sheets in laser cutting, stamping, bending, and other processes.

Metal Processing Plants: Suitable for bulk handling and stacking of metal sheets, especially during long-term, high-frequency operations, where automated equipment can effectively reduce errors and waste.

Home Appliance Manufacturing: Automated handling equipment can be used for transporting materials like refrigerator, washing machine, and air conditioner shells, enhancing the level of automation in production lines.

Automotive Manufacturing: In the processing of automotive body panels, automatic stacking and handling equipment ensures the safe transport of large sheet metal parts.