Features and specifications of 300mm, 350mm, and 450mm flatbed die cutters, commonly used for precise cutting in packaging, labels, and other industries.

1. 300mm Flatbed Die Cutter

Specifications:

Max Cutting Width: 300mm

Cutting Speed: 18000m/H

Material Types: Paper, thin cardboard, adhesive labels, plastic films

Thickness Range: -0.05-0.05mm

Power Consumption: 8.5 kW

Operation Mode: Fully automatic or semi-automatic feeding system

Machine Dimensions: Approx. 2600mm × 1350mm × 1950mm

Weight: 1400kg

Key Features:

Small Format Design: Ideal for label and sticker cutting, packaging samples, and small-scale production.

Digital Control: CNC or PLC control system for precise operation.

Automatic Registration: Ensures precise alignment with printed materials.

User-Friendly Interface: Touchscreen operation for easy control.

Compact and Efficient: Suitable for tight spaces, with minimal power consumption.

2. 350mm Flatbed Die Cutter

Specifications:

Max Cutting Width: 350mm

Cutting Speed: 18000/H

Material Types: Cardboard, paper, plastics, foam, adhesive labels

Thickness Range: -0.05mm - 0.05mm

Power Consumption: 10.5 kW

Machine Dimensions: Approx. 2650mm × 1400mm × 1950mm

Weight: 1800kg

Key Features:

Versatility: Can handle a wider variety of materials compared to the 300mm model, suitable for medium-scale production.

Automatic Feeding System: For continuous material handling, reducing manual labor.

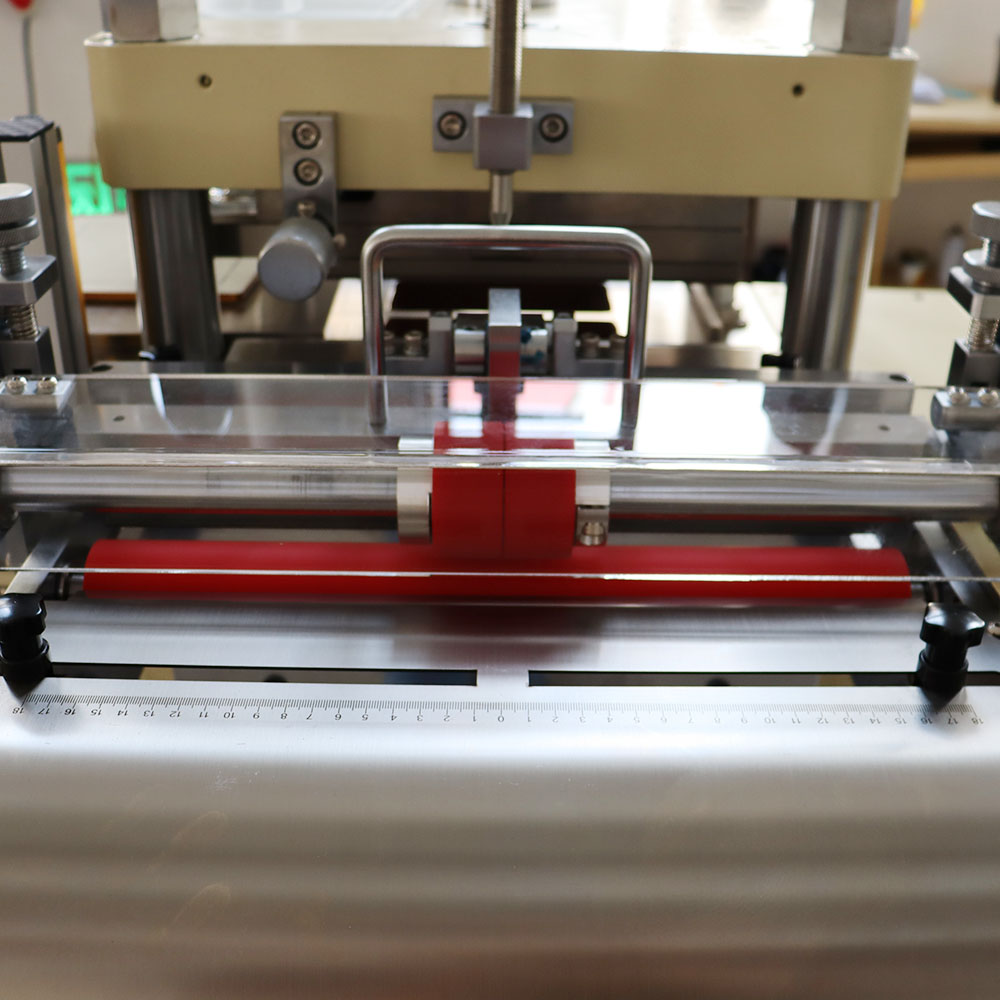

Precision Cutting: Equipped with an optical sensor for accurate positioning.

Waste Removal System: Built-in for quick disposal of cut-off materials, improving efficiency.

Multi-function: Capable of cutting, creasing, and perforating in a single pass.

3. 450mm Flatbed Die Cutter

Specifications:

Max Cutting Width: 450mm

Cutting Speed: 12000/H

Material Types: Cardboard, paper, plastics, foam, adhesive labels

Thickness Range: -0.05mm - 0.05mm

Power Consumption: 13kW

Machine Dimensions: Approx. 2750mm × 1450mm × 1950mm

Weight: 2300kg

Key Features:

Heavy-Duty Design: Suitable for industrial-scale production and large batch runs.

Precision and Speed: Can cut through thicker materials with enhanced speed, maintaining accuracy.

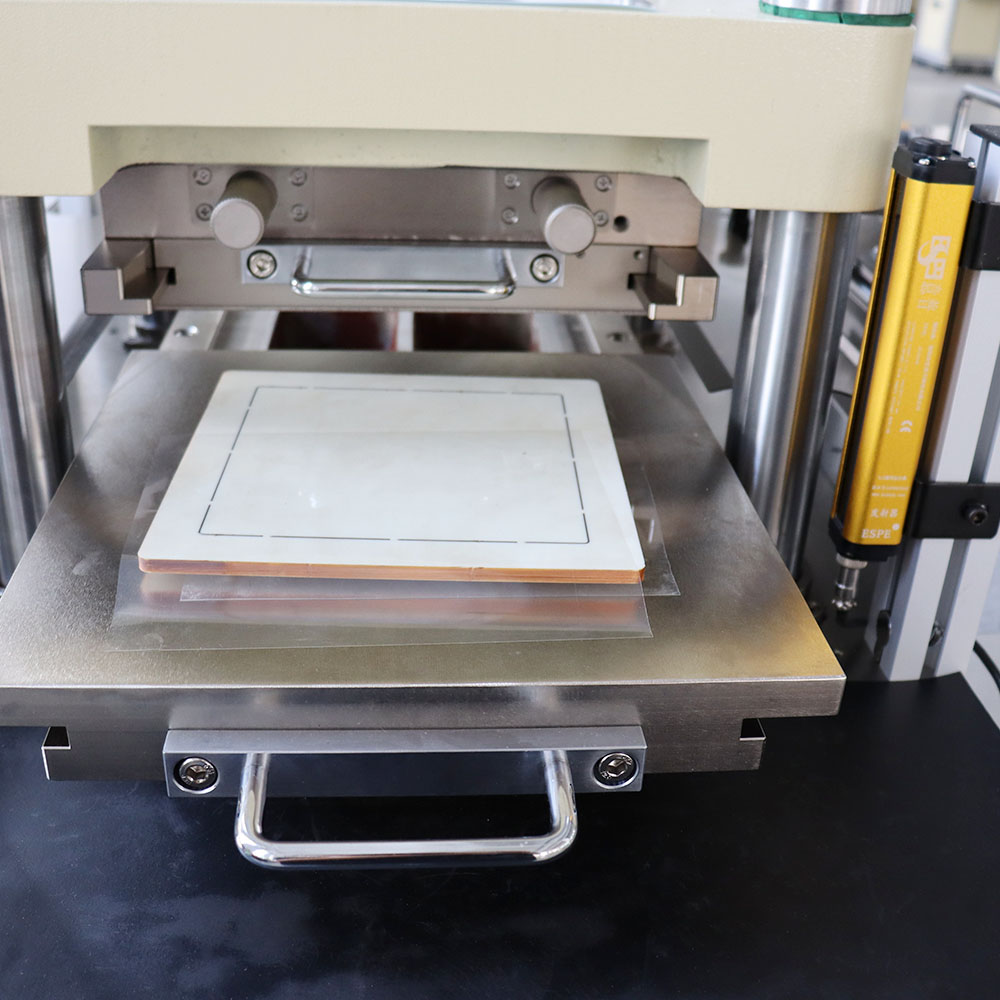

Multi-Process Integration: Allows die cutting, creasing, embossing, and more in one machine.

Automatic Feeding and Collection: Efficient workflow with minimal operator intervention.

High Throughput: Ideal for larger formats such as boxes, labels, packaging inserts, and other medium-sized products.

Waste Reduction: Efficient use of materials with minimal wastage through precision cutting.

Common Features Across All Models:

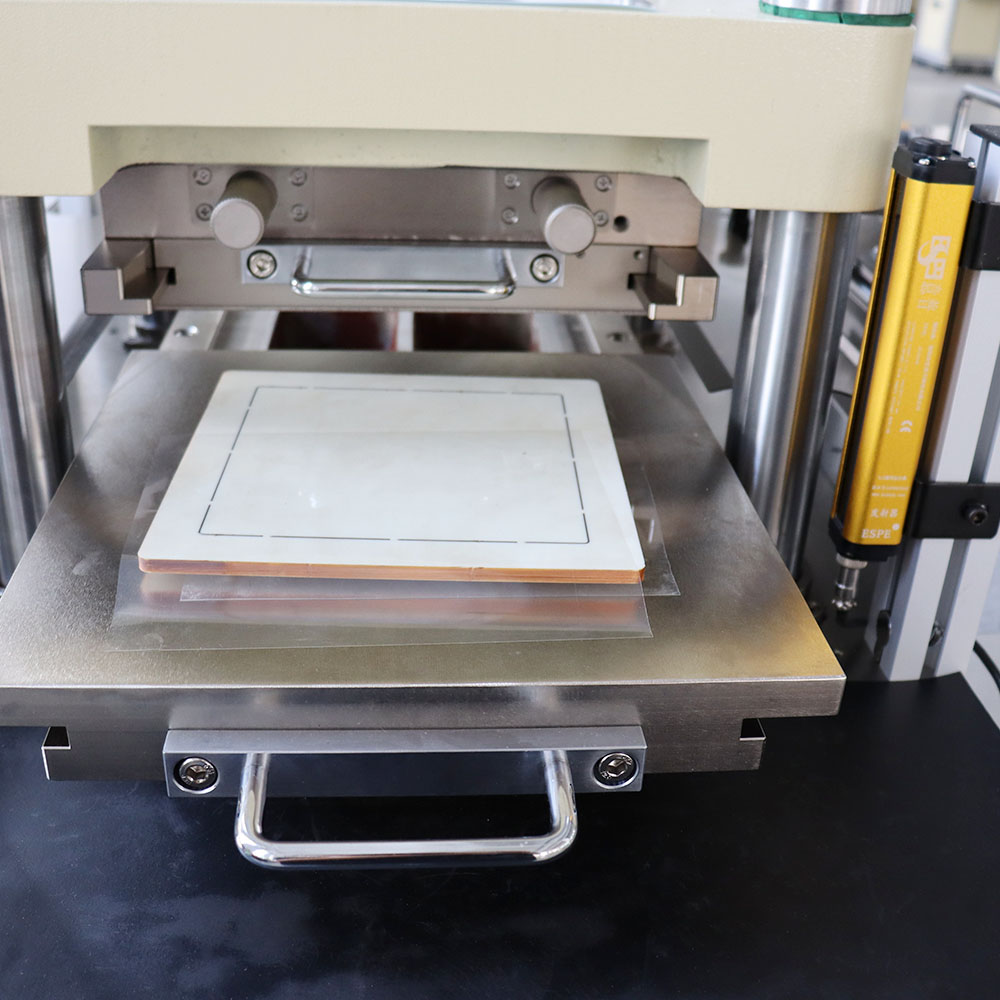

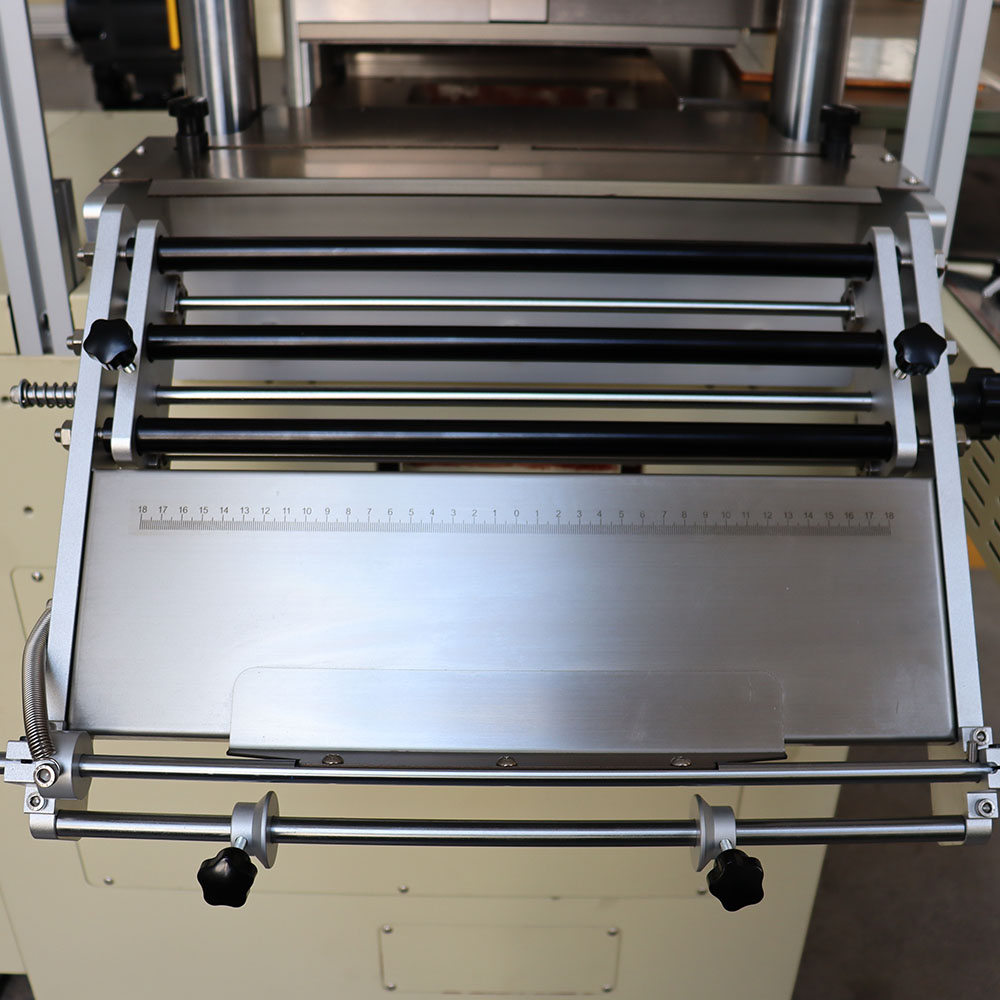

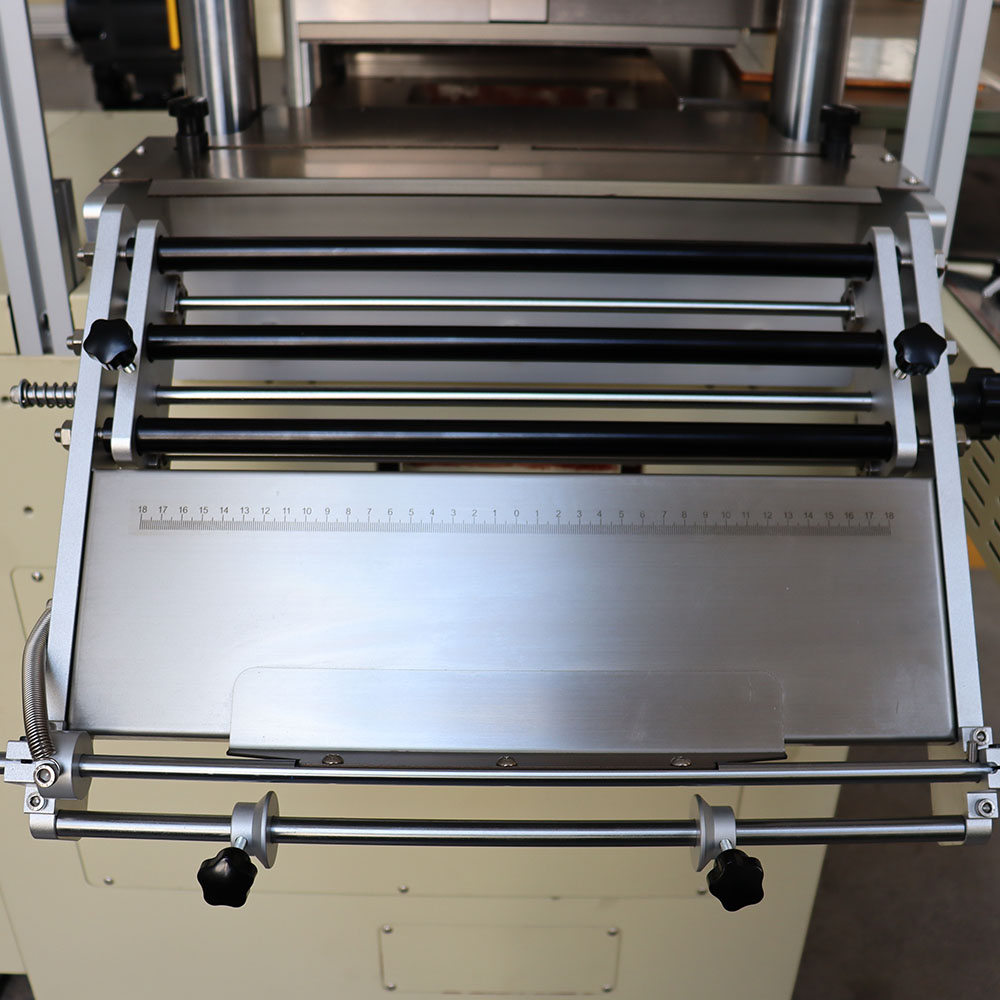

Cutting Precision: High-precision die-cutting using servo motors or stepper motors, with registration systems for printed materials.

Touchscreen Interface: Easy-to-use interface with job setup, adjustments, and program storage for repeated tasks.

Safety Features: Equipped with sensors and guards to ensure safe operation.

Durability: Built with robust frames to handle continuous use in industrial environments.

Customizable: Can be equipped with additional units like creasers, embossers, or stripping units based on production needs.

These flatbed die cutters—ranging from 300mm, 350mm to 450mm—are versatile machines suitable for various applications, from small-scale label production to industrial-level packaging and sheet cutting. The choice of model depends on the specific requirements for cutting width, material thickness, and production volume.

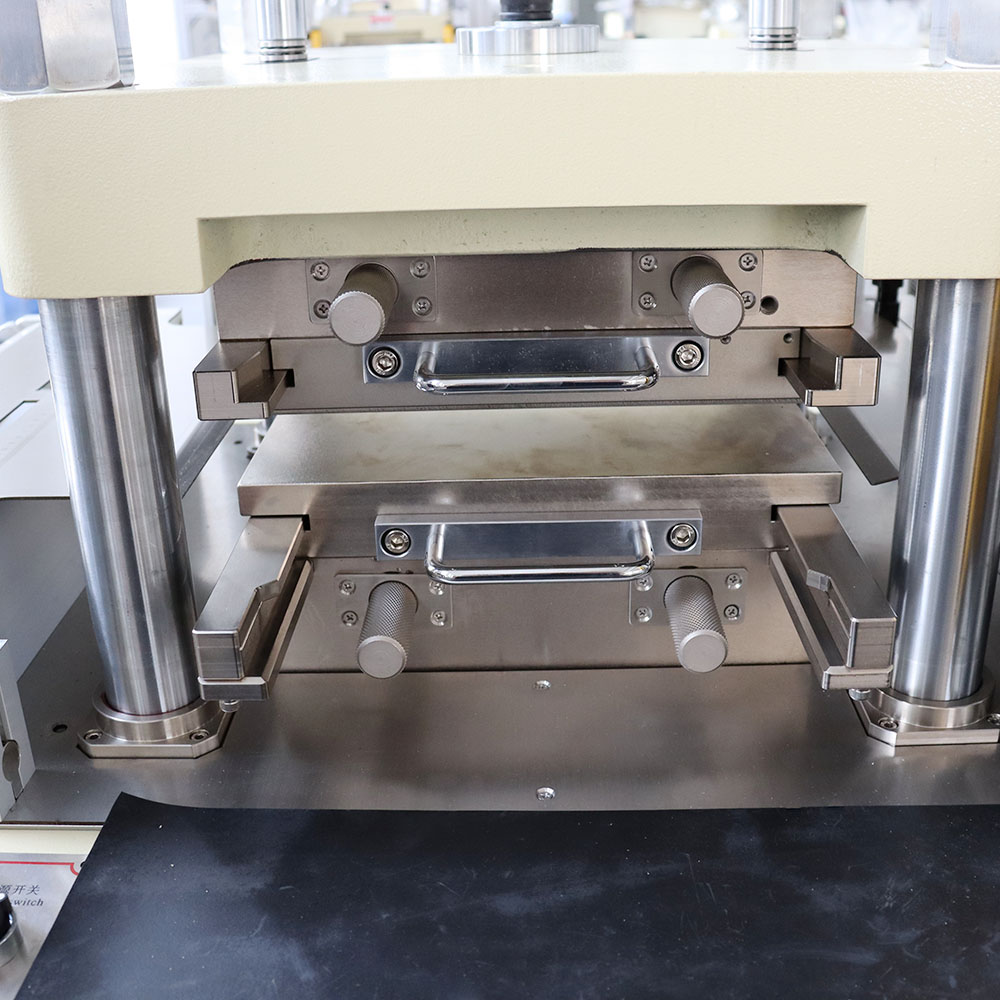

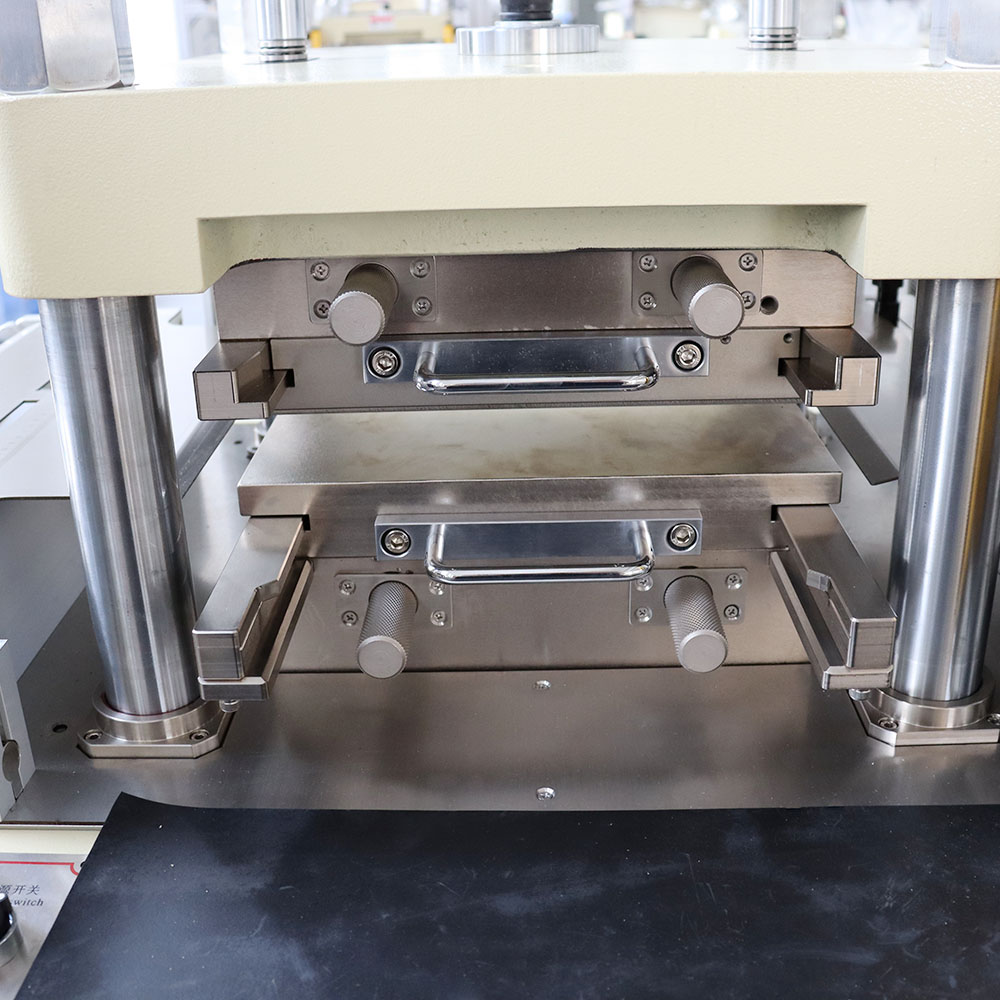

Technical Specifications:

| Specifications | JCY-300 | JCY-350 | JCY-450 |

| Feed Width | 310 mm | 370 mm | 470 mm |

| Max. Die Cutting Area | 300 × 310 mm | 350 × 370 mm | 450 × 470 mm |

| Max. Operating Speed | 18000 punches/hour | 18000 punches/hour | 12000 punches/hour |

| Punching Stroke | 28 mm | 28 mm | 28 mm |

| Pressure Regulation | 30 mm | 30 mm | 30 mm |

| Voltage Regulation Accuracy | 0.005 mm | 0.005 mm | 0.005 mm |

| Drawing Accuracy | ±0.05 mm | ±0.05 mm | ±0.05 mm |

| Upper Form Size | 300 × 310 × 37 mm | 350 × 370 × 37 mm | 450 × 470 × 37 mm |

| Lower Template Size | 300 × 310 × 40.5 mm | 350 × 370 × 40.5 mm | 450 × 470 × 40.5 mm |

| Overall Dimensions | 2600mm × 1350mm × 1950mm | 2650mm × 1400mm × 1950mm | 2750mm × 1450mm × 1950mm |

| Machine Weight | 1400 kg | 1800 kg | 2300 kg |

| Air Source Specification | 0.5–0.7 MPa | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Total Power | 8,.5 kW | 10.5 kW | 13 kW |

| Lubrication Mode | Intermittent fuel supply | Intermittent fuel supply | Intermittent fuel supply |

| Applicable Die Types | Plywood mold, wood mold | Plywood mold, wood mold | Plywood mold, wood mold |

Performance Characteristics:

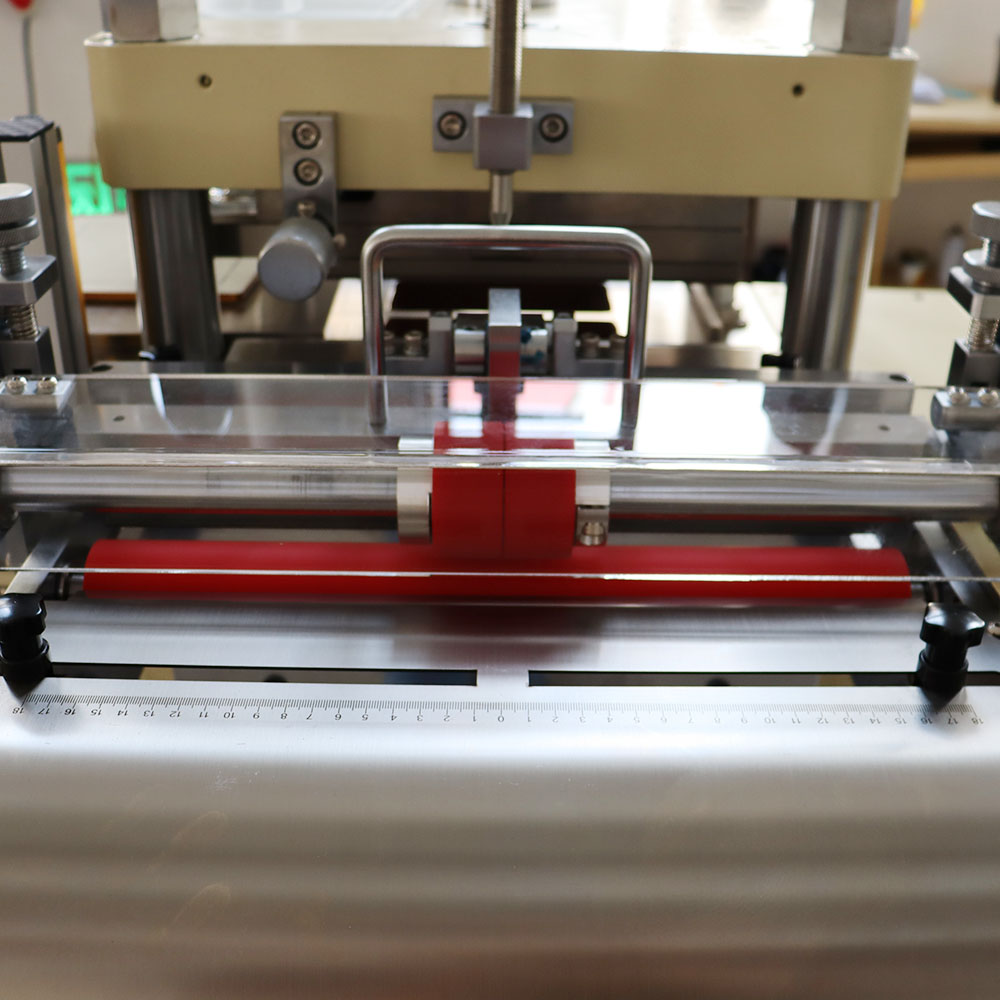

Small hole positioning instant correction device.

Double servo drive for stable pressure, low noise, and precise drawing.

Electric digital display for quick and convenient voltage adjustment.

High punching force with stable die-cutting pressure.

QDC mold allows multiple high precision nesting die cutting to be achievable.

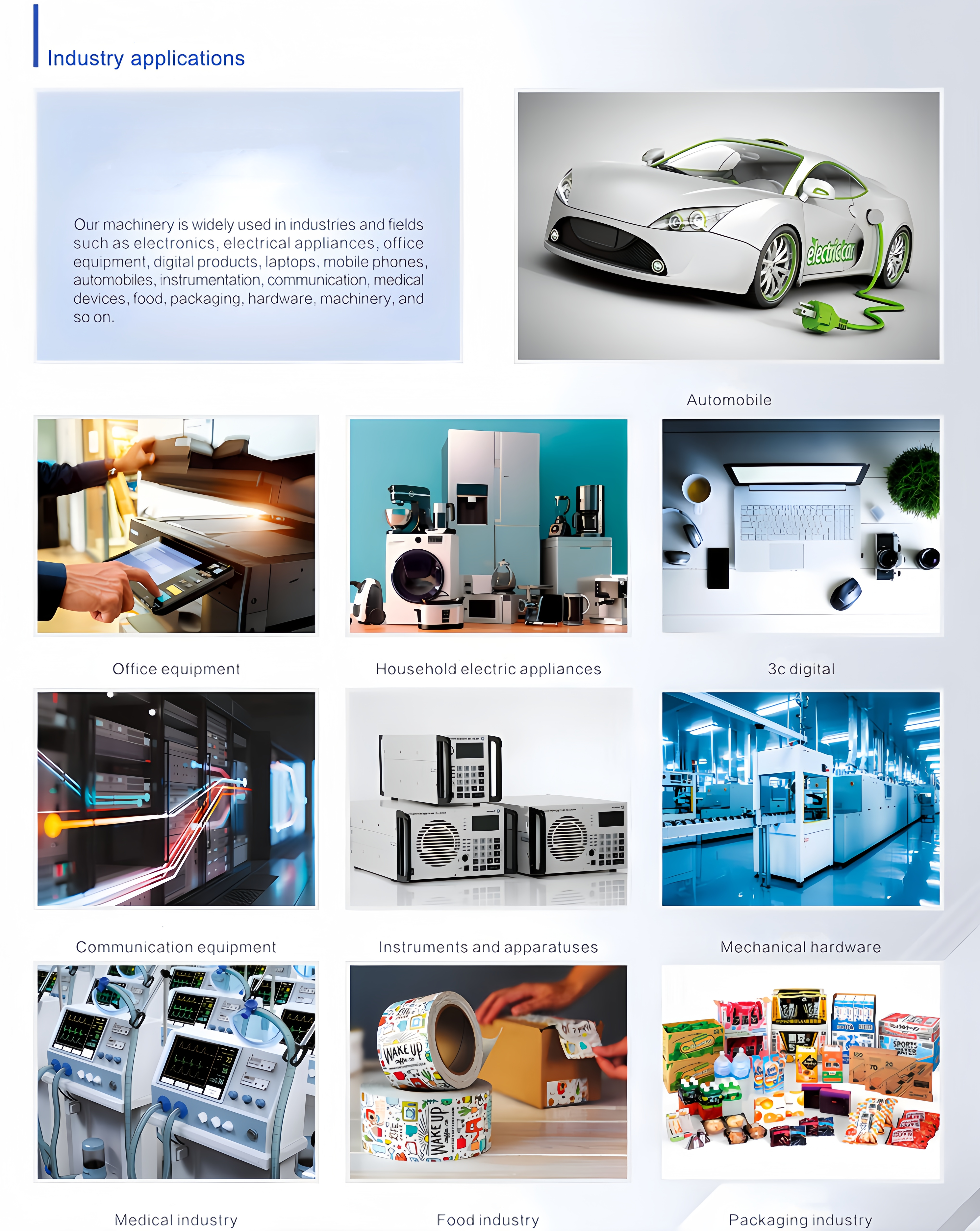

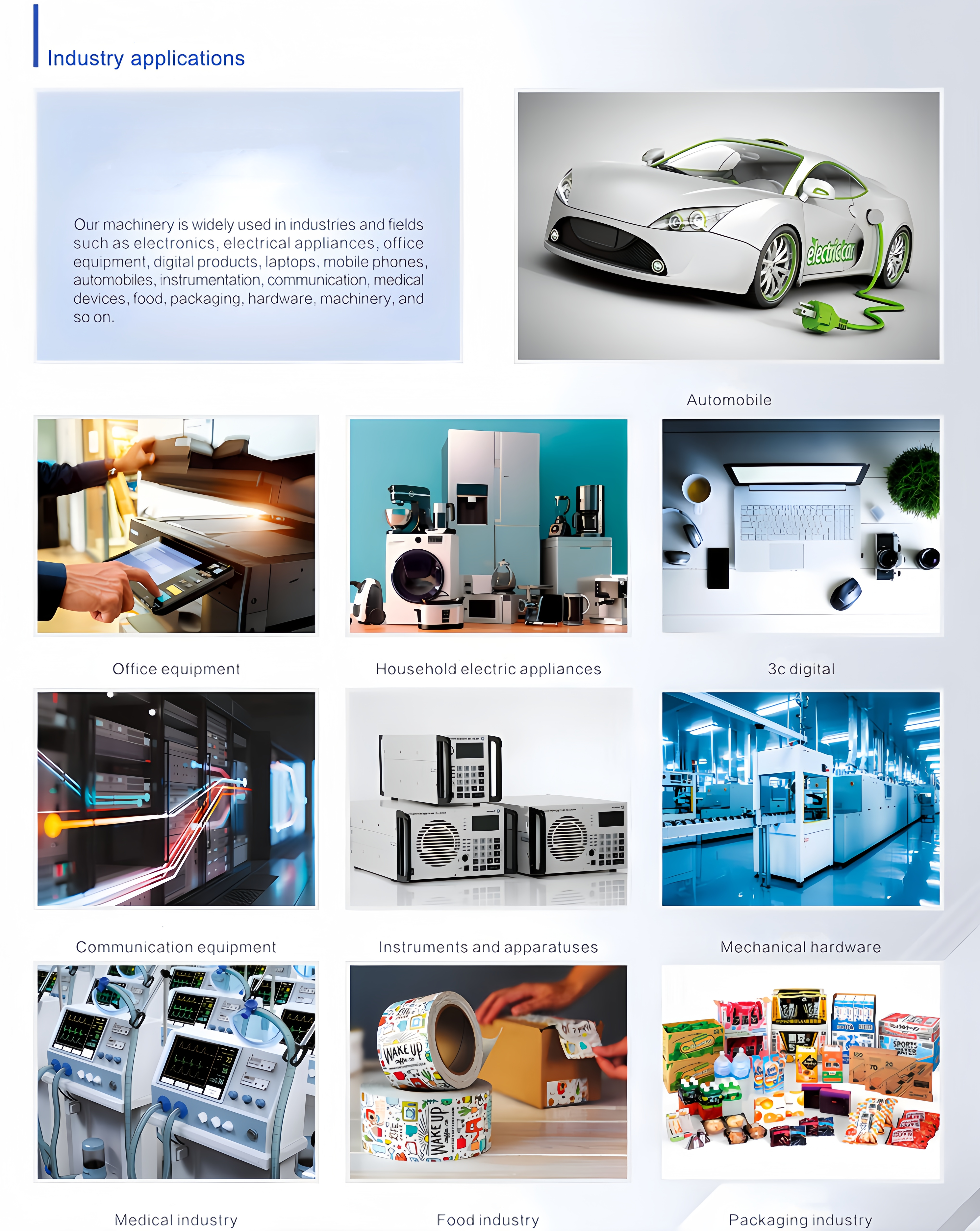

Applications:

This machine is well-suited for industries that require precision die cutting for materials like plywood, wood, and other specialized molds. It is particularly useful in:

The JT-D650/D850 ensures high production efficiency, accurate results, and versatility for a wide range of die-cutting needs.