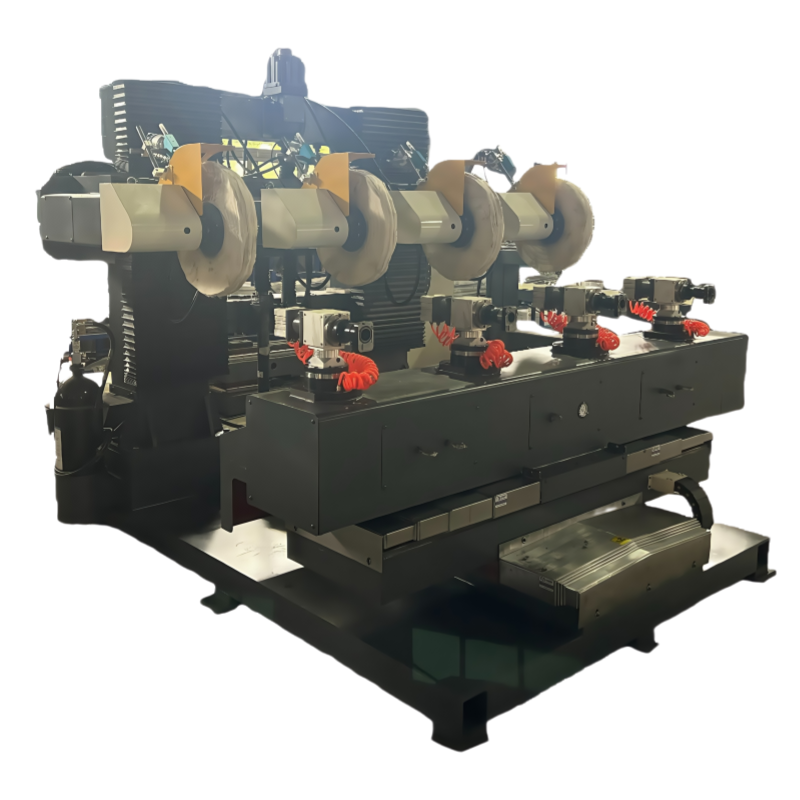

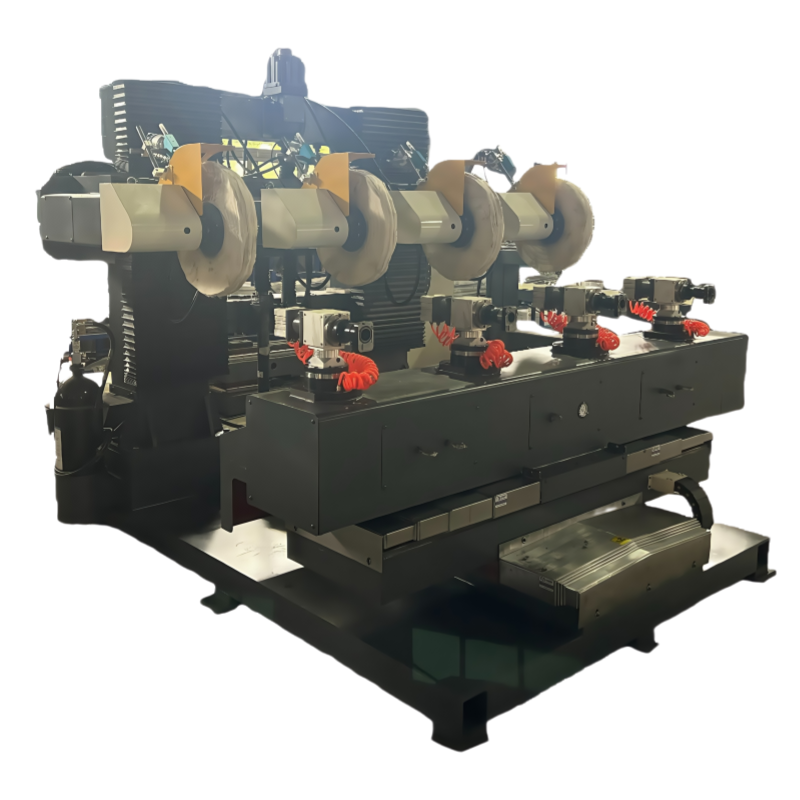

CNC Polishing Machine for Polishing and Brightening Faucet Elements, Faucets, Bathroom Fittings, and Faucet Handles

The CNC Polishing Machine for Polishing and Brightening Faucet Elements is an advanced automated system designed specifically for high-precision polishing, brightening, and finishing of complexly shaped parts. Whether you are polishing faucets, bathroom fittings, faucet handles, or other sanitary components, this machine guarantees optimum finish quality, high production rates, and flexibility, all while maintaining low operating costs.

Equipped with five programmable interpolating CNC axes, this machine allows for extremely precise control over the polishing process. The CNC system provides automated, highly repeatable operations, ensuring consistent results for each part, making it ideal for high-volume production in industries that require consistently high-quality surface finishes. The integration of state-of-the-art technology ensures that even the most complex geometries can be processed efficiently and with outstanding quality.

Key Features and Benefits

Five Programmable Interpolating CNC Axes: The machine is equipped with five programmable interpolating CNC axes, which enable precise movement and polishing control across multiple dimensions. This allows for polishing even the most intricate parts, such as faucet handles with curved surfaces, shower handsets, or complex faucet fittings. The machine’s ability to handle complex geometries without manual intervention reduces labor costs, minimizes errors, and improves overall efficiency.

Automated Polishing of Complex Parts: This CNC polishing machine is specially designed for the automated polishing of parts with complex shapes and intricate surface features. Parts such as bathroom faucets, faucet handles, and shower head fittings often require detailed attention to the polishing process, with special consideration for areas such as seams, curves, and edges. The precision of the machine ensures that even these complex parts receive consistent, high-quality finishes, which would be difficult to achieve manually.

High Production and Flexibility: The machine excels in high production environments, capable of processing four parts simultaneously in each cycle. This not only increases throughput but also reduces cycle time per unit, which is essential for manufacturers looking to optimize production rates. Additionally, the machine is highly flexible, allowing for quick adjustments and reconfigurations to process various parts and finishes. Whether the parts are faucet elements, bathroom accessories, or faucet handles, the machine can handle a variety of components without significant downtime or manual intervention.

Versatile Applications: The machine can handle a wide range of applications, including:

This versatility makes the machine suitable for a variety of industries, including bathroom fixture manufacturing, hardware production, and sanitary ware manufacturing.

Deburring: Removing sharp edges or burrs from parts that are produced through processes like casting, cutting, or machining.

Grinding: Smoothing rough surfaces to prepare for polishing or to achieve a specific finish.

Polishing: Achieving a high gloss, reflective finish, ideal for faucets, handles, and bathroom fittings.

Satin Finishing: Producing a smooth, brushed appearance for products that require a matte finish.

Teach-In Programming: The teach-in programming feature allows operators to easily teach the machine specific movements or operations. This intuitive process eliminates the need for complex programming skills, enabling even non-technical operators to set up the machine with minimal training. The machine can store these parameters and recall them for future use, streamlining the setup process and ensuring consistent results across production runs.

Simultaneous Processing of Multiple Parts: A key feature of this CNC polishing machine is its ability to simultaneously process four parts of the same model in each cycle. This increases the machine's throughput, allowing manufacturers to polish multiple parts at once, reducing cycle time and boosting overall production efficiency. This capability is especially useful for high-volume manufacturers who need to maintain fast turnaround times without compromising on quality.

High-Quality Surface Finish: The machine guarantees a homogeneous surface finish across all parts, ensuring that each piece achieves the desired quality with precision. Whether you require a mirror finish, a satin finish, or a custom polishing standard, the machine can deliver consistent, high-quality results that meet the most demanding specifications. The automated process ensures that each part receives the same level of attention, eliminating human error and improving product consistency.

Automatic Spraying Gun Position Adjustment: The machine features automatic adjustment of the spraying guns to accommodate the diameter of the polishing mops. This ensures that the polishing process is efficient and consistent, regardless of the size of the part or the diameter of the polishing tool. This automatic adjustment feature reduces setup time and ensures a precise and accurate polishing process for each part.

Cost-Effective and Energy Efficient: The machine is designed to operate with low energy consumption and minimal use of consumables, such as polishing mops and compounds. This reduces operational costs and makes it an environmentally friendly choice for manufacturers. The efficiency of the CNC system, combined with its low wear-and-tear, helps extend the machine’s lifespan and lower maintenance costs, making it a sustainable investment in the long term.

Applications

Faucets and Bathroom Fittings: The primary application of the CNC Polishing Machine is in the production of faucets and bathroom fittings. The machine’s ability to polish brass, stainless steel, and other materials commonly used in faucets and fittings makes it an indispensable tool in this industry. The machine’s precision ensures that faucet components are polished to a mirror-like finish, which enhances the aesthetic appeal of bathroom fixtures.

Faucet Handles and Shower Head Polishing: In addition to faucet bodies, this machine is also capable of polishing faucet handles and shower heads. The CNC polishing process ensures that these components achieve a high-quality finish, with no visible defects or inconsistencies. The versatility of the machine allows manufacturers to produce parts that meet a variety of design specifications, from traditional designs to modern, sleek finishes.

Deburring and Grinding: The machine’s deburring and grinding capabilities are essential for cleaning up parts produced through processes like casting, molding, or machining. The removal of burrs or rough edges is crucial for ensuring the functionality and safety of faucets and fittings. This machine can deburr and grind parts quickly and efficiently, ensuring that the surfaces are ready for further finishing processes like polishing or satin finishing.

Benefits

Increased Production Capacity: With the ability to process four parts at once, the machine significantly increases production efficiency and reduces downtime between cycles.

Improved Surface Finish Quality: CNC-controlled polishing ensures a high-quality, homogeneous finish without any imperfections, making it ideal for high-end bathroom fixtures.

Flexibility in Production: The machine can handle a wide variety of parts and finishes, ensuring it can be adapted to meet changing production needs with minimal setup time.

Reduced Operating Costs: With low energy consumption, minimal use of consumables, and automation, the machine helps reduce the overall cost of production while improving efficiency.

Conclusion

The CNC Polishing Machine for Polishing and Brightening Faucet Elements is a cutting-edge solution that combines high production efficiency, low operating costs, and unmatched flexibility. Whether polishing faucets, bathroom fittings, faucet handles, or shower heads, this machine delivers consistent, high-quality finishes with minimal human intervention. Its five programmable interpolating axes, ability to process multiple parts simultaneously, and capability to handle a wide range of materials and finishes make it an indispensable tool for modern manufacturing facilities. The machine is ideal for manufacturers looking to scale production, improve surface finish quality, and reduce operational costs, making it a valuable asset for any factory producing bathroom fixtures and sanitary components.