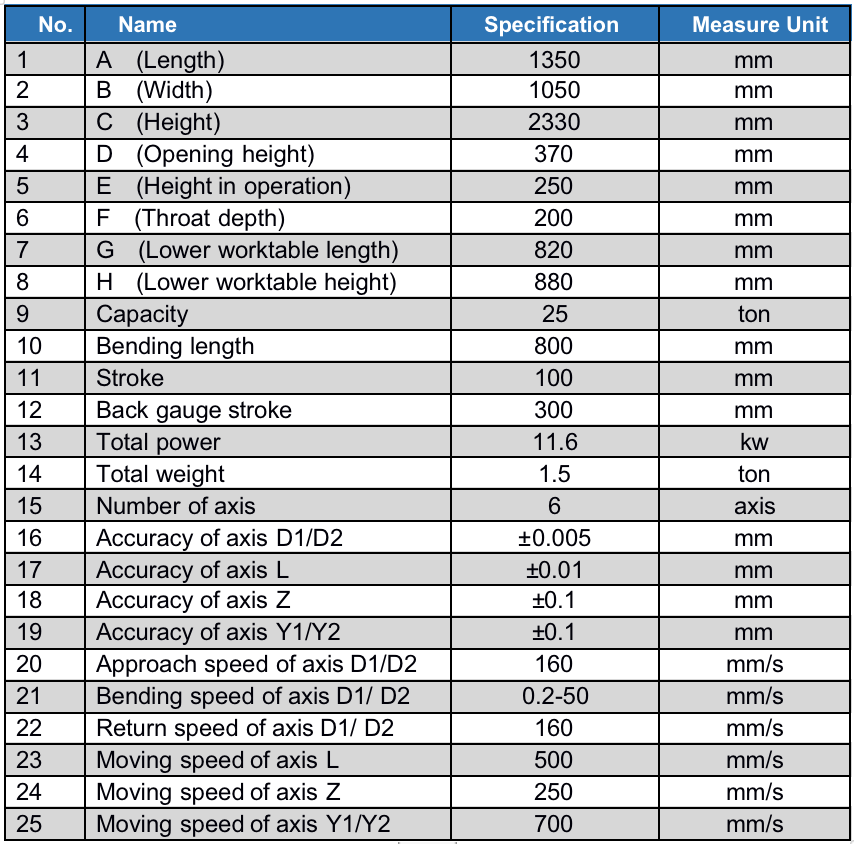

ES2508 CNC Electric Press Brake 6 axis Bending Machine 800mm Automatic press brake

The CNC bending machine is used to bend the metal sheet in cold state into workpieces of various geometric section shapes by using the equipped moulds (general or special moulds). It is a sheet metal forming machine designed for cold rolling sheet metal processing, and is widely used in sheet metal bending processing in automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicle and other industries.

The bending machine is to use the equipped mold (general or special mold) to bend the metal plate in the cold state into workpieces of various geometric cross-section shapes. The bending machine generally uses the special CNC system for the bending machine. The coordinate axis of the bending machine has developed from a single axis to 12 axes. The CNC system can automatically realize the control of the sliding block's running depth, the adjustment of the sliding block's left and right tilt, the front and back adjustment of the rear stopper, the left and right adjustment Pressure tonnage adjustment and slider approaching working speed adjustment, etc. The bending machine can conveniently realize the sliding block downward, inching, continuous, pressure maintaining, return, midway stop and other actions, and complete the multi elbow bending at the same angle or different angles with one feeding.

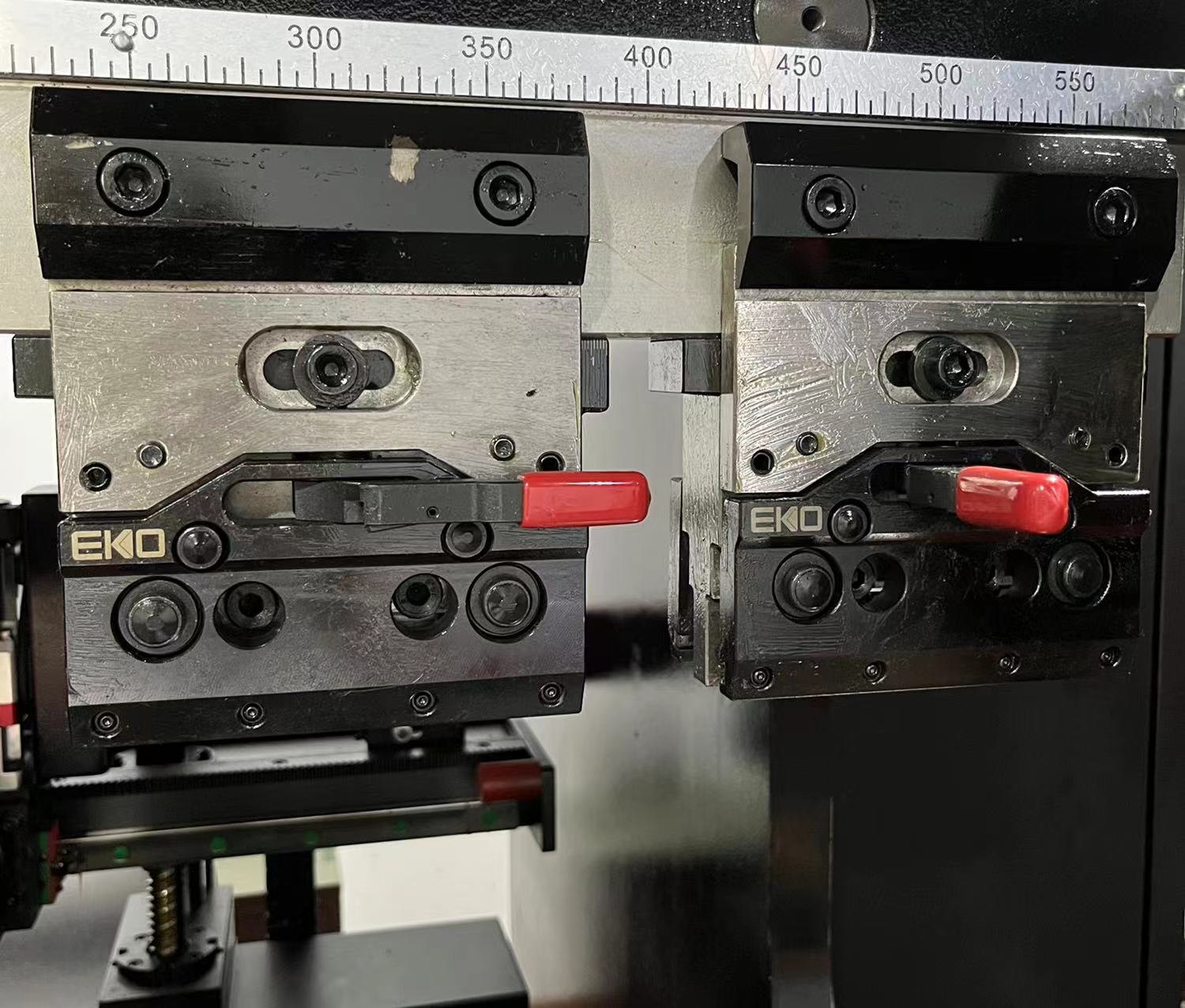

WILA new standard and clamping system

DSP Italy laser protection

The DSP laser guarding system ensures safe operation. Optical protection remains active until the tool opening is reduced to 2mm, thereby preventing fingers and hands from entering the point of operation.The DSP laser guarding system ensures safe operation. Optical protection remains active until the tool opening is reduced to 2mm, thereby preventing fingers and hands from entering the point of operation.

Kyokko quick clamping system

The Japanese style quick clamping system ensures simple, fast and safe front load tool changing, elimi- nating the time-consuming

nature of the traditional tool change method.

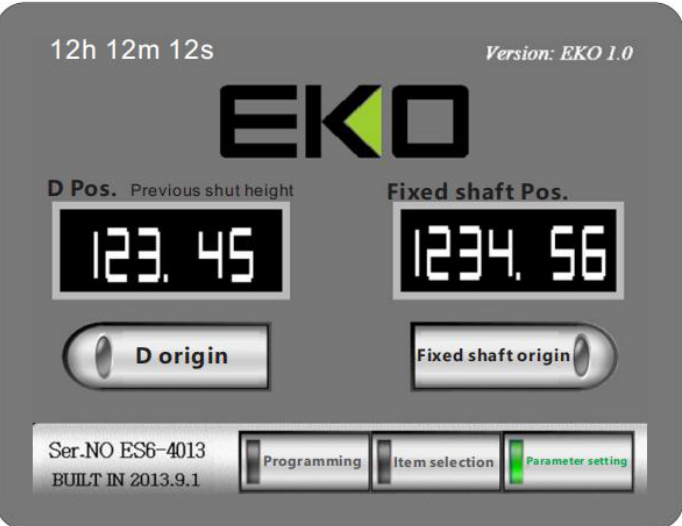

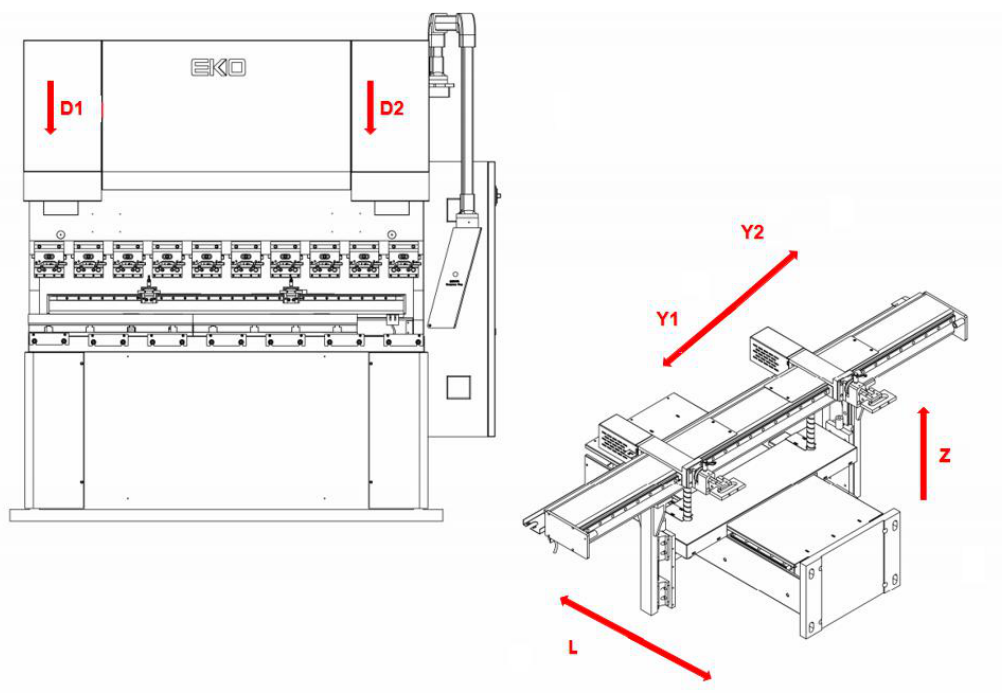

EKO press brake up to 6 axis

ES2508 with 6 axis, D1-D2-Y1-Y2-L-Z. It can meet your mult -type of bending angle.

Powerful SANYO DENKI servos

The left and right ram are controlled by heavy duty servo drives and motors from Japanese giant Sanyo Denki. Unmatched in durability, these large format servo motors allow accurate bending with up to 125 tonnes of force. The left and right ram are controlled by heavy duty servo drives and motors from Japanese giant Sanyo Denki. Unmatched in

durability, these large format servo motors allow accurate bending with up to 125 tonnes of force.

MITSUBISHI servo drives & motor

The back gauge is driven by premium Japanese servo motors from Mitsubishi Electric. These high speed servos ensure rapid and precise move

Q1. What is average life of machine

A1:Under normal use, the lifespan is 10-15 years.

Q2. What are drawback compare to hydraulic servo macjine?

A2:I don't quite understand the second question, is it comparing servo with traditional hydraulic? If so, The biggest disadvantage of our servo compared to hydraulic is expensive. But you get what you pay for.

Q3. What are benefit compare to hydraulic servo?

A3.Compared to hydraulic, the benefit of EKO press brake is high accuracy, high efficiency, Stable and environmental friendly.

(1)We imported servo motors(SANYO, from Japan) making the eqiupment precise,stable and durable;

(2)The lead screws and guide rails are imported C5grade products with high accuracy, excellent performance and log service life;

(3)Environmental friendly does not use hydraulic oil that is a pollution source difficult to be disposed. After the traditional hydraulic pressure is used for a long time, the temperature of the sealing ring is too high, the accuracy will be inaccurate, and oil leakage will occur, resulting in a dirty floor. We have seen it at the customer site.

Q4. What major problem can be faced?

A4.EKO‘s frame is better than all other competitors. We use Q345E steel, which has a high carbon content. This steel ensures the strength and stability of our machine. And the heat treatment of our equipment is the best in China. We use two sets of quenching and tempering heat treatment. The maximum temperature is 1200 degrees, 48 hours. The above two points are the reasons why it is difficult for other companies to do well in servo press brakes. That's why our machines are stable and durable.

Q5. Any safety, if insert thick metal for bend?

A5.We have not encountered any problems. The problem that has occurred is that the customer operating system is not adjusted properly, and the operation is improper. Many programs can be set in the system. Our equipment has no wearing parts. We have showroom or office in Dongguan city, Fujian, Chengdu, Wuhan, Shanghai, Suzhou, Hangzhou, Beijing, Tianjin and Shandong. How could you imagine that we just need 4 after-service man?

Q6. If machine down, can recover quickly?

A6.It depends on the problem. If the problem is small, it is a piece of cake. The specific situation will be analyzed in detail.