MK-400PLUS Fully Automatic 5-Axis Complex Insert Grinder

Advanced Solution for Precision Grinding of Indexable Inserts

The MK-400PLUS is a cutting-edge, fully automatic 5-axis CNC insert grinder, purpose-built for high-precision, high-efficiency grinding of standard and complex indexable inserts. With capabilities for periphery grinding, double-sided chamfering, and intricate 3D profile machining, the MK-400PLUS brings unparalleled flexibility and automation to the world of precision tool manufacturing.

Engineered for the processing of superhard materials such as carbide, cermet, ceramic, and CBN, this grinder is ideal for insert manufacturers requiring tight tolerances, stable productivity, and high automation in mass production environments.

⭐ Application Scope

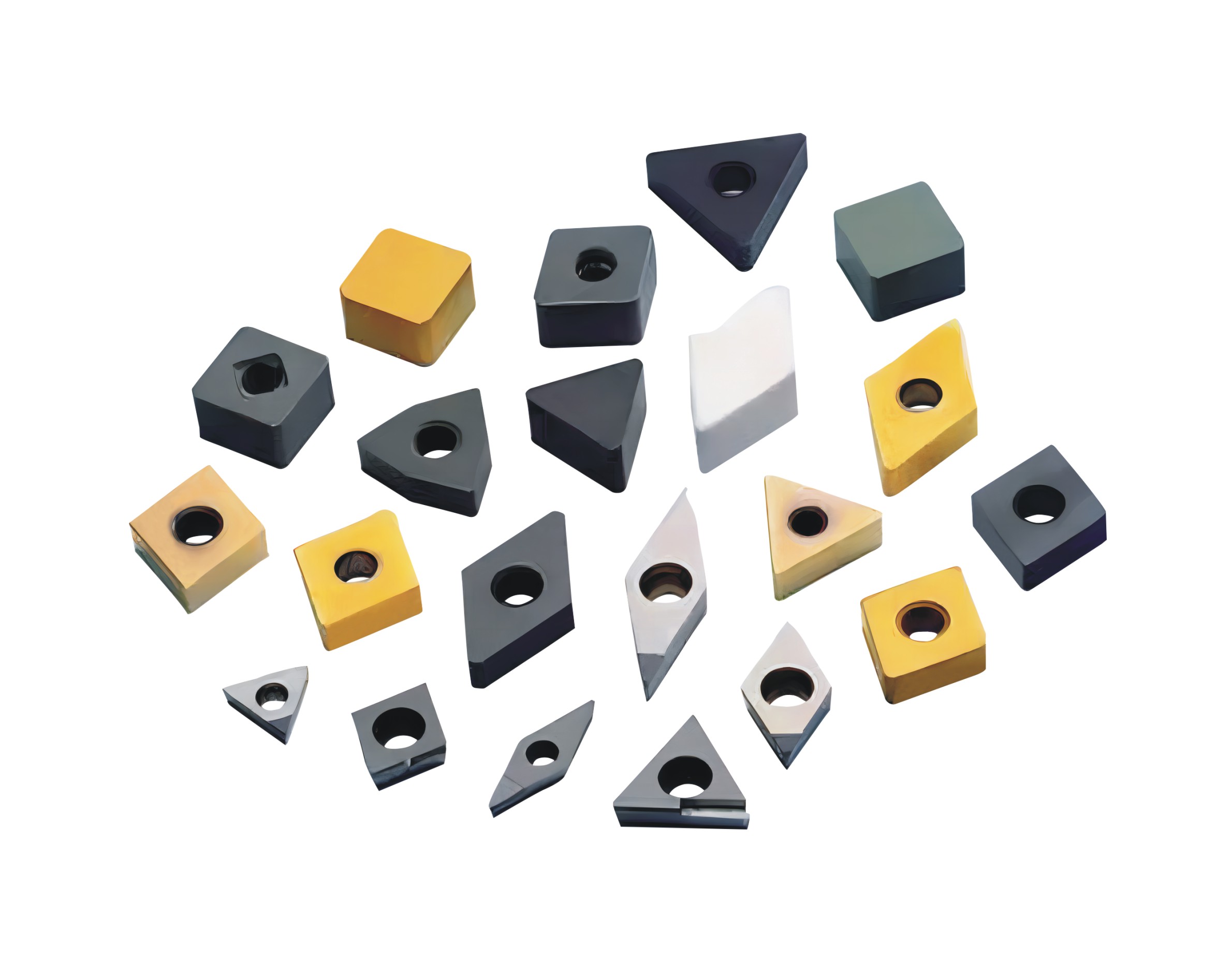

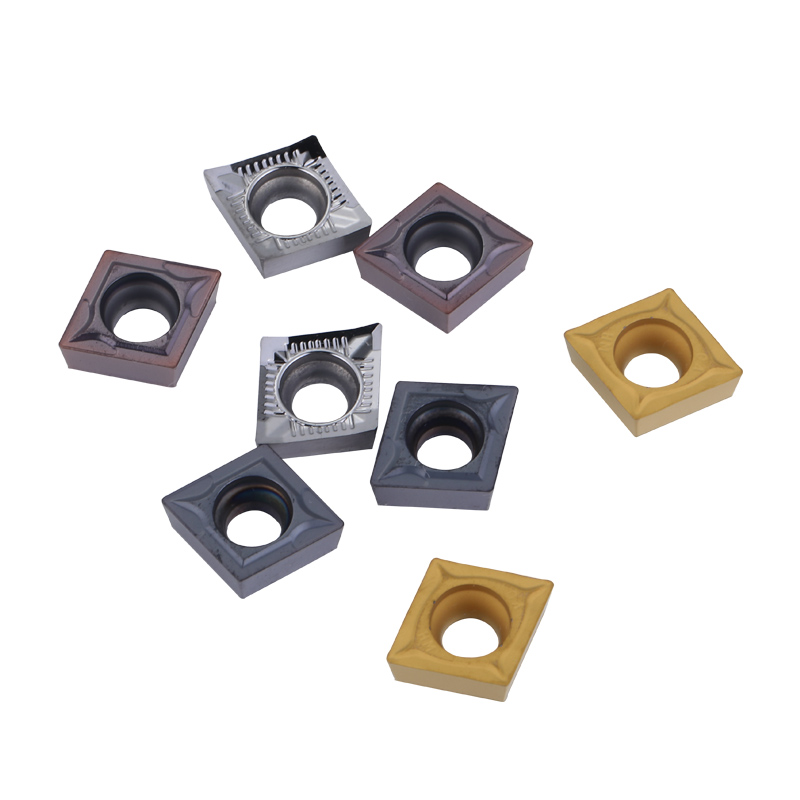

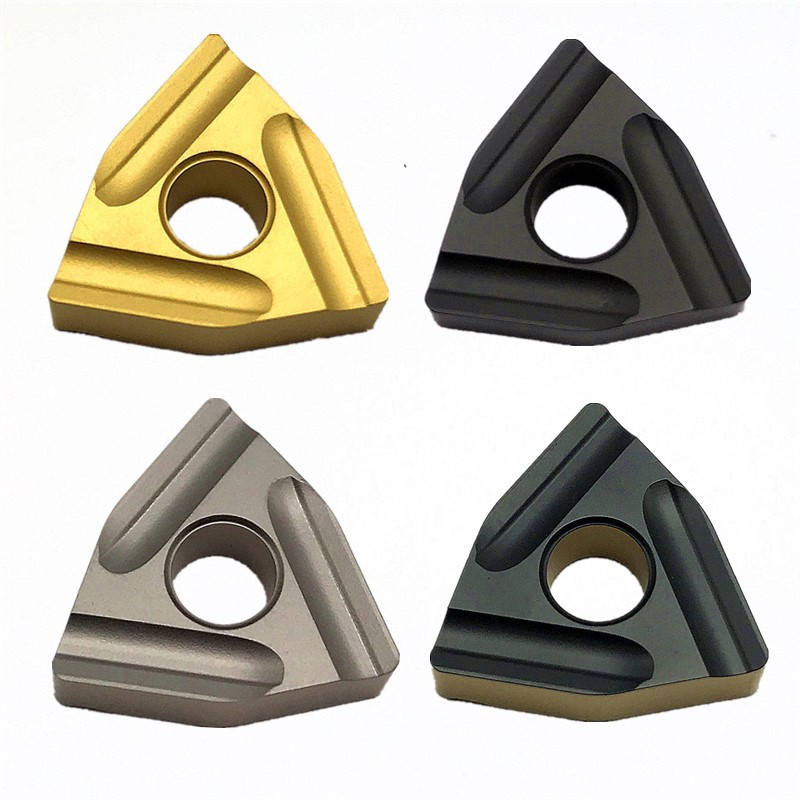

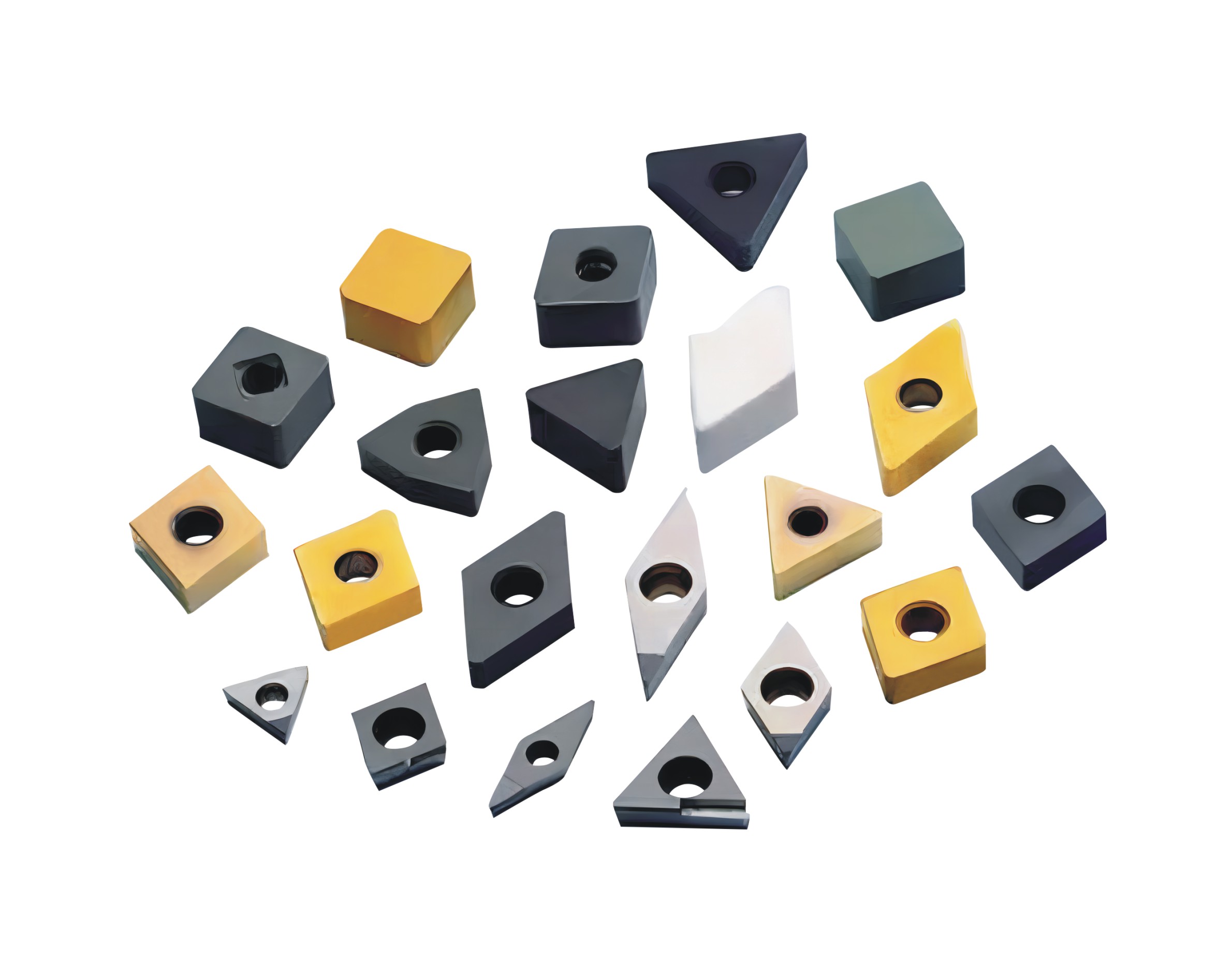

Insert Types: Standard indexable inserts, complex-shaped inserts with 3D geometries

Operations: Full periphery grinding, double chamfering, chipbreaker profiling

Materials Supported:

Technical Specifications

| Parameter | Specification |

| Minimum Inscribed Circle | 3.5 mm (equilateral triangle), 4.7 mm (other shapes) |

| Maximum Circumscribed Circle | 45 mm |

| Maximum Insert Thickness | 15 mm (Can process up to 3 pieces of 4.76 mm simultaneously) |

| Main Spindle Motor | 7.5 kW 3-phase induction motor, V3 class |

| Tailstock Clamping Pressure | Max. 10 kN (at 7 MPa hydraulic pressure) |

| Machine Dimensions | 2,475 mm (W) × 2,250 mm (D) × 2,160 mm (H) |

| Machine Weight | 5,500 kg |

| Power Supply | AC 380V (50/60Hz), 25 kVA |

| Air Supply | ≥ 0.5 MPa, Air Consumption: 250 N/min |

| Hydraulic Pressure | Max. 7 MPa |

⚙️ Axis Configuration & Motion Control

| Axis | Function |

| X-axis | Left-right oscillation – with automatic centralized lubrication |

| Y-axis | Feed axis – direct drive with centralized lubrication |

| A-axis | Workpiece rotation – extended swivel for complex contour grinding |

| C-axis | Table angle adjustment: -91° to +91° |

| V-axis | On-line cleaning for the main grinding wheel |

| W-axis | Core positioning axis – manual blade positioning |

| B1-B3 axes | Control axes for robotic tray handling (tray transfer, lifting, feeding) |

Max. Simultaneous Control Axes: 9 axes via a built-in CNC control system (non-PC-based)

Automation & Workpiece Handling

Robotic Workpiece Loader

Type: 3-axis linear coordinate robotic arm

Functions: Automated supply and unloading of inserts

Gripper: Single gripper for insert pick-up and placement

Tray Options:

This fully automated loading/unloading system ensures continuous production with minimal operator intervention—ideal for mass production and lights-out manufacturing.

Measurement, Correction & Quality Control

Integrated Detection System:

This closed-loop quality assurance ensures dimensional accuracy and production consistency.

️ Dressing & Blade Positioning

Grinding Wheel Dressing Device

Motor: 1.5 kW electric spindle

Dressing includes side and profile restoration

Supports long continuous production without compromising grinding quality

Insert Core Positioning System

️ Design, Build & Safety

High Rigidity Structure: Ensures mechanical stability and micron-level repeatability even under heavy-duty loads.

Compact Footprint: Space-saving layout (under 2.5m wide), suitable for various factory configurations.

Fully Enclosed CE-Compliant Design: Provides operator safety, dust protection, and noise isolation, supporting cleanroom or precision workshop standards.

Optimized Maintenance: Centralized lubrication and component accessibility simplify service and reduce downtime.

Energy Efficiency: Powered by high-efficiency components and energy-saving control systems.

Software Compatibility & Programming

The MK-400PLUS is designed with operator usability and software continuity in mind:

Fully compatible with Agathon’s ToolLab application (standard)

Seamless integration with Evo platform accessories and tooling

Smooth transition for users of other brands, with intuitive UI and guided programming

Flexible programming:

ToolLab enables:

Standardized insert parameter entry

Automatic toolpath generation

Real-time simulation and geometry preview

Reuse and adjustment of existing programs

✅ Key Advantages

Grind periphery, chamfers, and chipbreakers in a single clamping

Support for up to 3 inserts simultaneously

9-axis CNC control for high-precision 3D geometry machining

Integrated in-process measurement and correction

Compatible with PCD, CBN, ceramic, carbide and more

Optional 3D probing for automatic geometric verification

Automated robotic tray system for high-volume production

CE-certified safe, enclosed environment

Minimal operator involvement with maximum productivity

Ideal For

Insert manufacturers seeking to automate and scale

Tooling companies focused on tight tolerances and complex geometries

High-mix, low-volume as well as large batch production

Global companies seeking a Swiss-quality precision grinding platform

MK-400PLUS: Redefining Insert Grinding Performance

With full 5-axis control, intelligent automation, industry-leading accuracy, and smart integration, the MK-400PLUS is not just a grinder—it’s a next-generation solution for manufacturers who refuse to compromise on quality, efficiency, or flexibility.