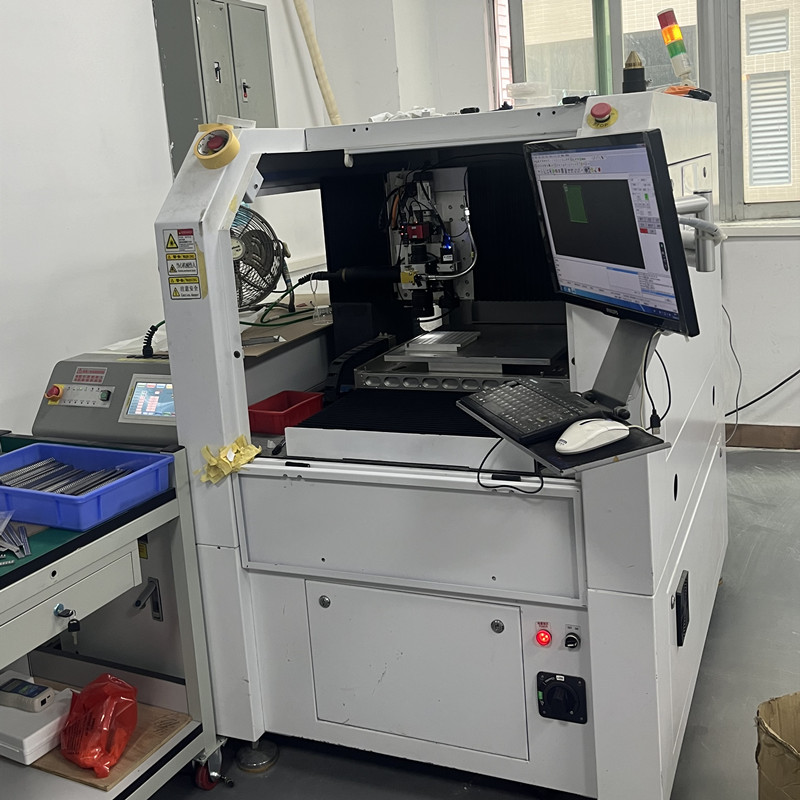

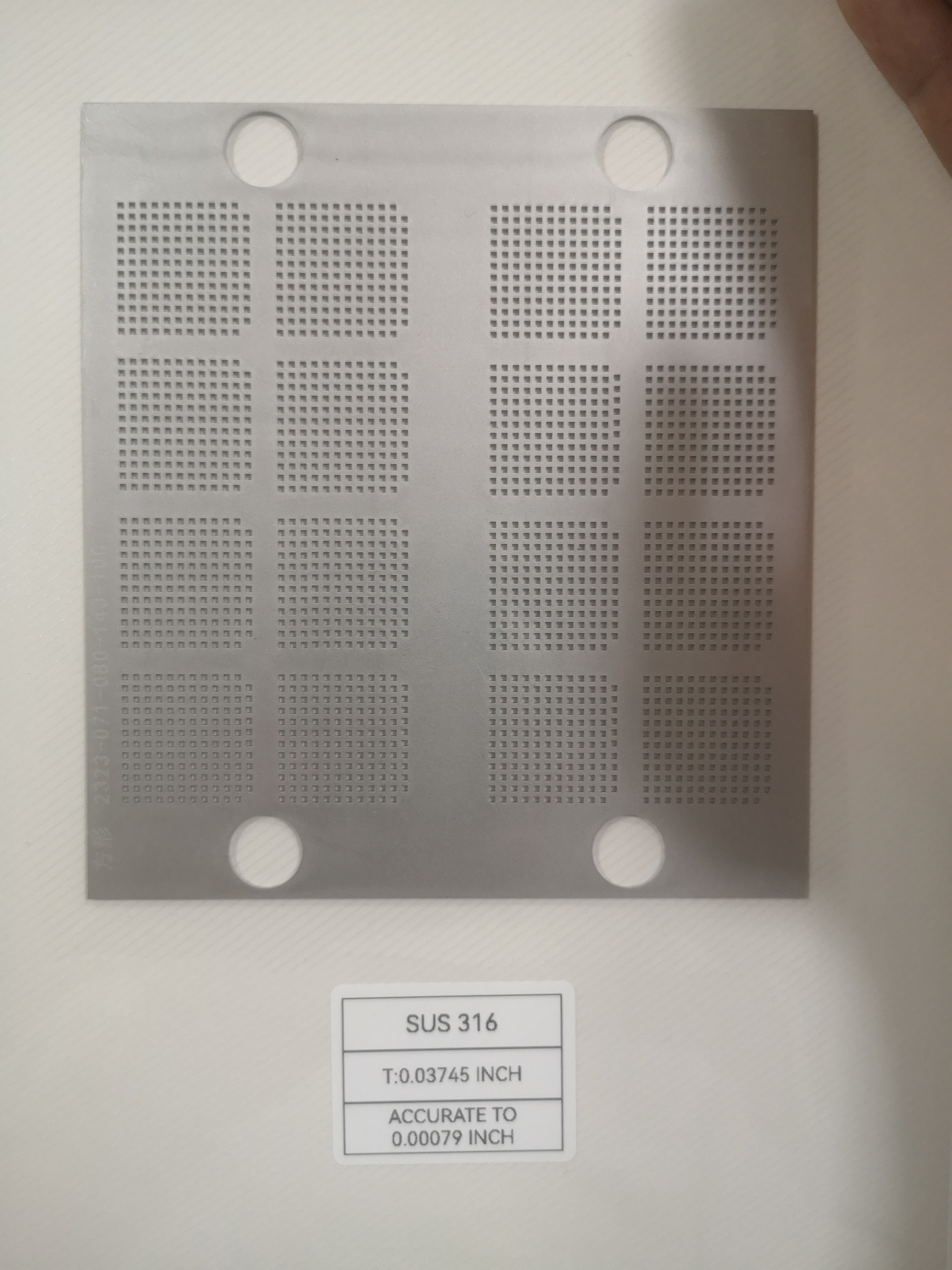

Precision Laser Cutting Services for SMT Inspection Templates / Inspection Overlays

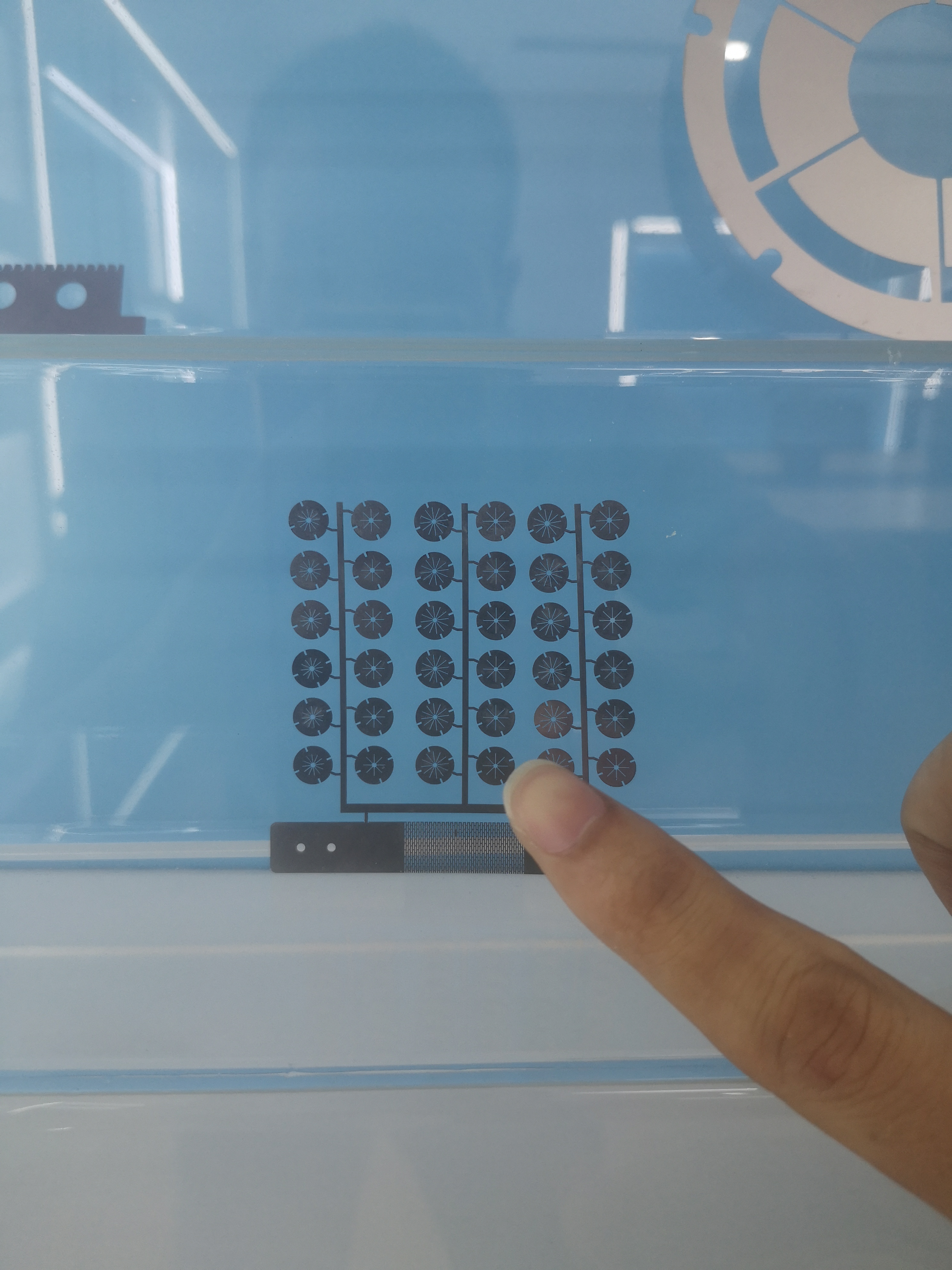

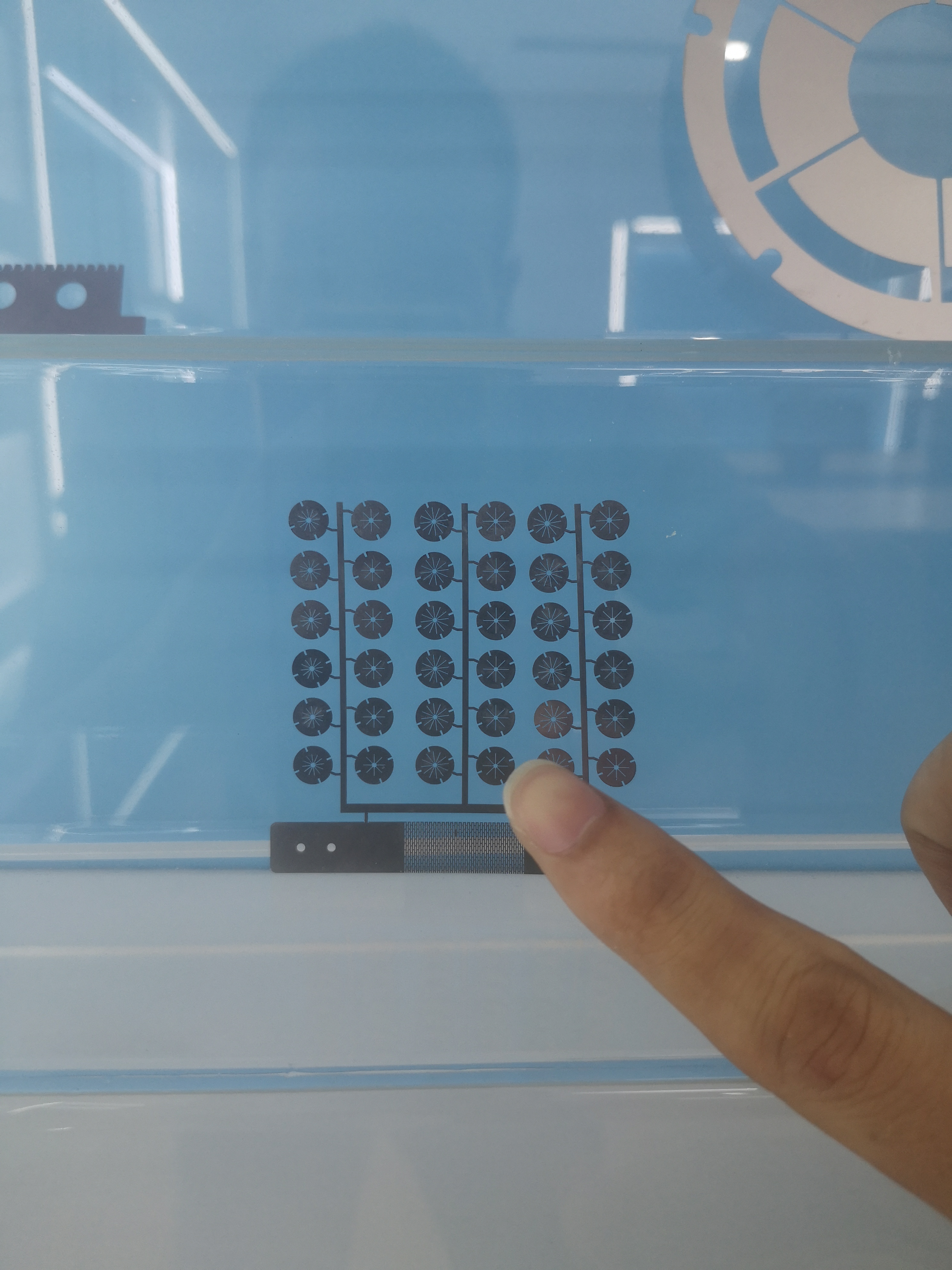

Stencils Unlimited specializes in SMT inspection templates that utilize precision laser cutting technology to create highly accurate openings for easy overlay on assembled printed circuit boards (PCBs). Our inspection templates help verify the correct placement of SMT (Surface-Mount Technology) and PTH (Plated Through-Hole) components on your PCBs. They provide an efficient and reliable alternative to traditional manual visual inspection, improving speed and accuracy in the inspection process.

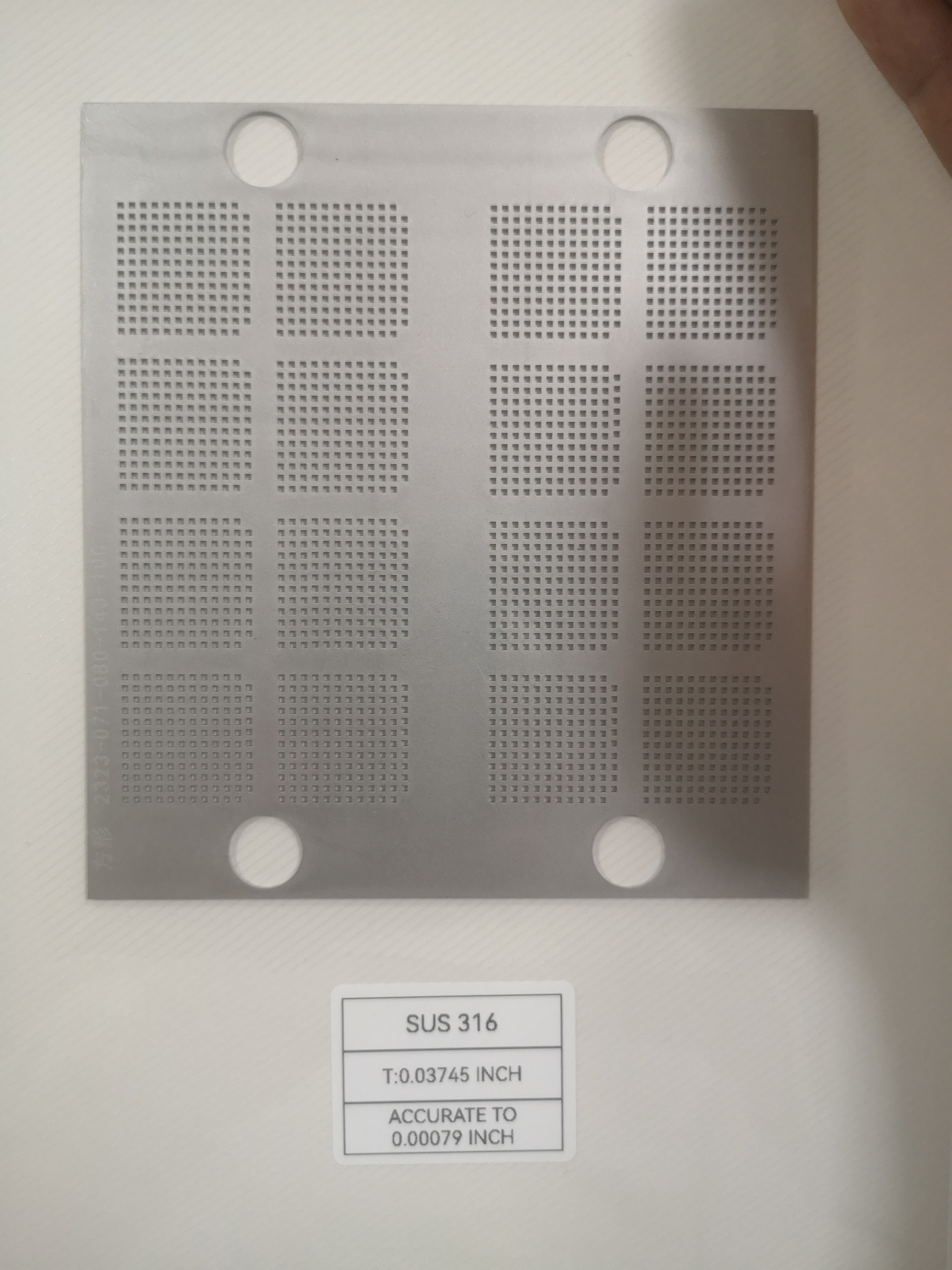

We offer SMT inspection templates in a variety of materials and thicknesses, with stainless steel being the most common choice. Our precision laser cutting ensures:

Minimum feature size of 0.002" (50 microns), ideal for the intricate requirements of SMT and PTH inspection.

Aperture tolerance within 0.00025", ensuring precise openings for component verification.

Custom material thicknesses ranging from 0.002" to 0.020" to suit different inspection needs.

Maximum size of 22.5"x29" for larger PCBs and custom templates.

Laser engraving for adding polarity markings, text (reference designators), and other critical information directly onto the template.

Key Benefits

Faster and More Accurate than Visual Inspection:

Templates help speed up the inspection process and reduce the likelihood of errors that may arise during visual inspection.

By placing the template over the assembled board, the operator can immediately focus on verifying component placement, ensuring alignment and polarity.

Improved Production Cycle Efficiency:

Catch wrong or missing parts early in the production cycle, preventing costly rework or scrap.

By guiding the inspector’s eyes to specific locations, the template helps reduce errors and improve overall inspection accuracy.

Reduced Training Time for New Hires:

Templates serve as clear visual aids, reducing the amount of time new employees need to get trained on inspection procedures.

This leads to faster ramp-up times and a more efficient workforce.

Highly Accurate, Cost-Effective, and Safe:

Our precision laser cutting technology ensures high accuracy while minimizing costs.

The process reduces the chances of missing misaligned or incorrectly placed components, ensuring product reliability.

Reduced Scrapped Parts:

Data and Design Requirements

We require PCB Gerber files to design your SMT inspection template. The necessary layers include:

Outline layer

Soldermask layer

Solder paste layer

Silkscreen layer

We can accept several file formats for the design submission, including Gerber, DXF, HP-GL, and HP-GL2. Including a PDF drawing of the design is recommended for reference. We will send a check plot for your approval before proceeding to production, ensuring that the template is accurate and meets your specifications.

Applications

SMT inspection templates are commonly used in:

PCBA (Printed Circuit Board Assembly) processes to ensure proper placement and orientation of components.

Quality control (QC) checks during or after assembly to ensure the board meets the design specifications.

Production monitoring for high-volume assembly processes, where speed and accuracy are paramount.