DP GROUP, founded in 2016, offer professional laser solutions and sheet metal fabrication machinery. Headquartered in Hong Kong, we operate three factories in mainland China:

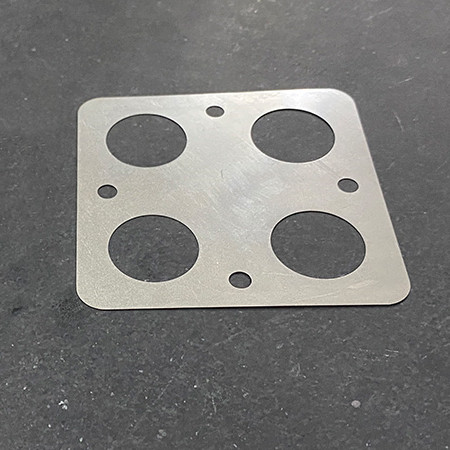

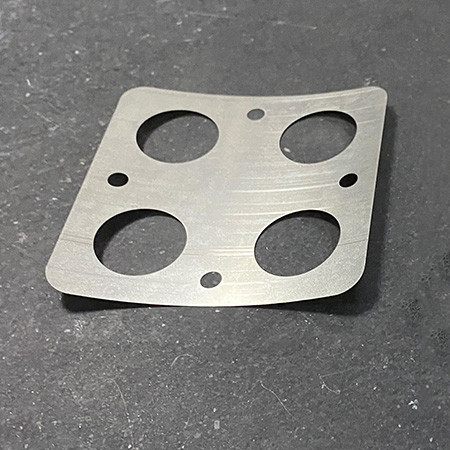

DPMach (Dongguan): Specializes in laser cutting, welding, and marking.

DGDY (Dongguan): Focuses on press brake machines with advanced Panel Bender technology.

DPQG (Foshan): Manufactures large tube laser cutting machines for pipes up to 800mm in diameter and 30 meters lenth.