160 Tons of Bending Force: This press brake provides a bending force of 160 tons, capable of handling large and thick metal sheets with ease. It is designed to meet the demands of heavy-duty metal bending applications.

4100mm Bending Length: With a bending length of 4100mm, it can accommodate long sheet metal pieces, making it perfect for larger metalwork projects.

CNC Control System: The advanced CNC control system offers precise control over the bending process, allowing for easy setup, quick adjustments, and high repeatability in production runs. It ensures high precision in bending angles and tolerances.

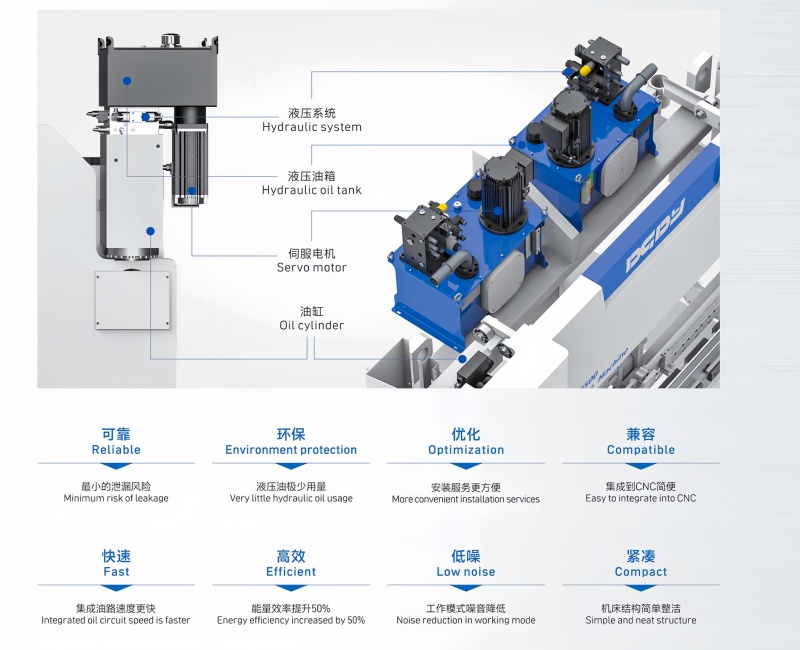

Hydraulic-Electro Servo Hybrid Drive: The hydraulic-electro servo hybrid system integrates hydraulic power with electric servo motors to provide on-demand energy usage, reducing overall energy consumption and increasing the efficiency of the bending process.

Servo Hydraulic System: The servo motors optimize the performance of the hydraulic system by adjusting pressure and flow rates in real time, ensuring precise control of the bending force and cycle time.

Precision and Accuracy: The machine features advanced backgauge systems, ram positioning technology, and automatic die compensation for precise and repeatable results, ensuring minimal deviation in bending angles and shapes.

High Productivity: With rapid downstroke and return speeds, this press brake offers excellent productivity for high-volume operations, improving throughput while maintaining high-quality standards.

Energy Efficiency: The integration of servo motors ensures reduced power consumption compared to traditional hydraulic press brakes, making it a more eco-friendly and cost-effective solution.

Safety Features: The press brake is equipped with advanced safety features, including light curtains, safety shields, and emergency stop buttons, providing a safe working environment for operators.

User-Friendly Interface: The CNC control system is easy to operate, featuring an intuitive touch screen interface that simplifies programming, adjustments, and operation.