3-Belt Metal Wide Belt Sander with Aluminum Oxide Sanding Belts (40/60/80/120/180/240/320/400/600/800 Grits)

The 3-Belt Metal Wide Belt Sander equipped with Aluminum Oxide Sanding Belts is an industrial-grade machine designed for high-efficiency metalworking applications. This versatile sander provides superior surface finishing, deburring, grinding, polishing, and material removal capabilities. It uses Aluminum Oxide belts with a wide range of grit sizes—40 grit to 800 grit—allowing users to adapt the machine to a variety of tasks, from rough sanding and heavy material removal to fine finishing and polishing. The result is a machine that can tackle a broad spectrum of surface treatments and materials, offering flexibility and precision in metal processing.

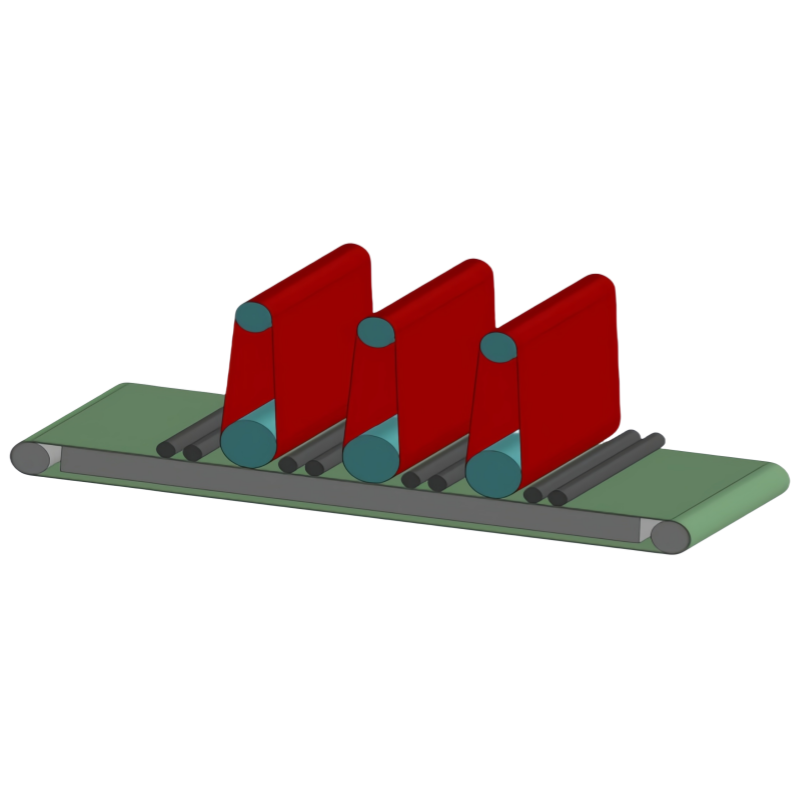

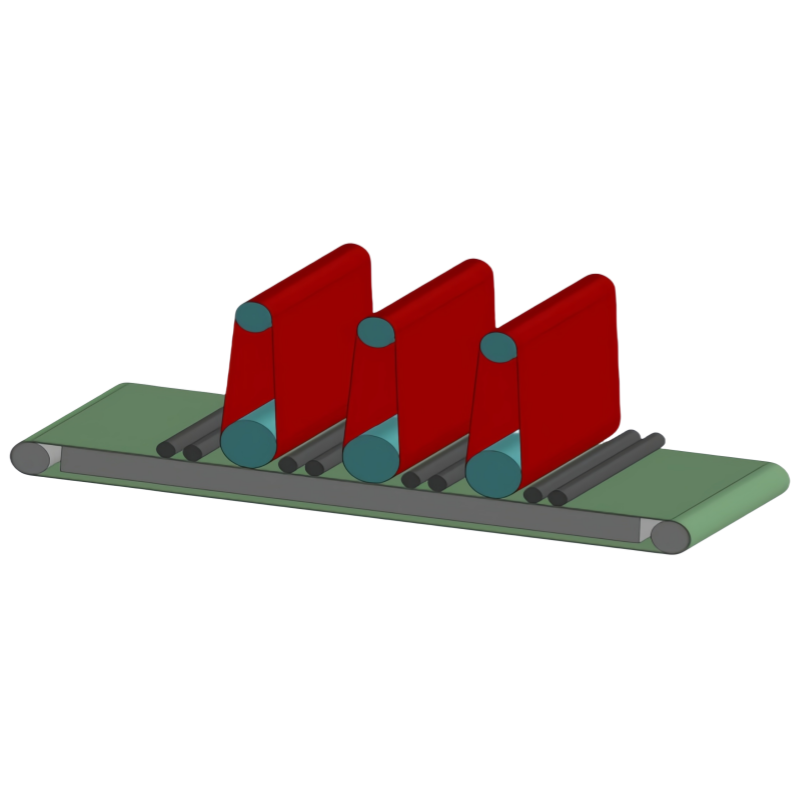

1. 3-Belt System for Versatility and Efficiency

The machine features a 3-belt system, allowing users to perform multiple operations in a single pass. The three sanding belts can be tailored for different levels of abrasion and polishing:

First Belt: Designed for heavy-duty material removal, rough sanding, and deburring.

Second Belt: Ideal for medium-grade sanding and smoothing surfaces, eliminating imperfections created by the first stage.

Third Belt: Provides a fine finish for final surface treatment, smoothing out any remaining scratches or marks.

The multi-stage sanding system ensures that the machine can handle a variety of tasks with ease, from aggressive sanding to fine finishing.

2. Wide Range of Grit Sizes (40 to 800 grit)

The sanding belts in this sander range from 40 grit (very coarse) to 800 grit (extremely fine), providing a comprehensive set of abrasives for different stages of material processing. This wide selection of grits makes the machine suitable for a range of materials, including metals, alloys, wood, and plastics. The different grit sizes allow for:

Coarse sanding (40-120 grit): Ideal for initial material removal, aggressive deburring, oxide skin removal, and heavy surface imperfections.

Medium grit (180-240 grit): Used for smoothing rough surfaces and preparing materials for finer finishes.

Fine grit (320-800 grit): Designed for polishing and achieving ultra-smooth finishes, often used in final sanding before coating or painting.

By combining these various grits, users can achieve consistent and precise results, making this sander ideal for high-end metalworking, wood finishing, and composite material treatments.

3. Aluminum Oxide Abrasive Material

The Aluminum Oxide abrasive used in the sanding belts is one of the most durable and cost-effective materials available. It is known for its hardness, resistance to wear, and long lifespan, making it perfect for both coarse and fine sanding operations. The properties of aluminum oxide include:

Longer Lifespan: Aluminum oxide belts maintain their cutting efficiency and durability over extended periods of use, reducing the need for frequent replacements and ensuring consistent performance.

High Cutting Power: The abrasives offer exceptional cutting power, making them ideal for aggressive sanding and heavy-duty material removal tasks.

Versatility: Aluminum oxide is effective on a wide range of materials, including steel, stainless steel, aluminum, brass, copper, plastic, wood, and composite materials.

This combination of grit selection and abrasive material ensures that the 3-Belt Metal Wide Belt Sander provides efficient results on a variety of substrates.

4. High Precision and Consistency

Precision is key when working with metal surfaces, and the 3-Belt Metal Wide Belt Sander excels in this area. Each belt is adjustable, ensuring that users can control the intensity of the sanding process and achieve highly accurate results.

Automated Feed System: The machine is equipped with a high-precision feed system that automatically adjusts the workpiece speed, ensuring uniform sanding and consistent results across large workpieces.

Constant Belt Pressure: The sander’s design ensures that sanding belts maintain consistent pressure on the workpiece, preventing uneven surfaces and ensuring smooth, consistent finishing.

Fine Adjustment Controls: Operators can make fine adjustments to the sanding belts to tailor the machine to specific tasks, ensuring the correct amount of material removal and avoiding over-sanding.

These precision features make the sander ideal for industries that require high-quality finishes, such as aerospace, automotive manufacturing, and metal fabrication.

5. Multiple Applications for Metalworking and Beyond

The 3-Belt Metal Wide Belt Sander is designed to meet the diverse demands of metalworking and other industries. Its versatility allows for the handling of various tasks, such as:

Deburring: The machine can effectively remove burrs, sharp edges, and imperfections caused by machining or cutting processes, ensuring smooth and safe parts.

Finishing: The sander provides a high-quality finish on a variety of metal surfaces. Whether polishing stainless steel or finishing aluminum, the sander is capable of delivering exceptional results.

Oxide Removal: The sander is highly effective at removing oxide layers, which are commonly found on steel, aluminum, and other metals.

Sanding and Grinding: It can also be used for light grinding and material removal, particularly for rust removal, surface preparation, and surface contouring.

Polishing: With finer grits, the sander can perform polishing tasks, leaving metal surfaces with a smooth and even finish.

This wide range of functions ensures the sander is suited for use in numerous industries, including automotive, aerospace, metal fabrication, and manufacturing.

6. Durable Construction for Heavy-Duty Use

The 3-Belt Metal Wide Belt Sander is built for industrial use, ensuring long-term durability and performance. The machine features a heavy-duty frame and robust components, capable of withstanding continuous operation in demanding environments.

Heavy-Duty Motors: The sander is equipped with powerful motors for each sanding belt and feeding system, ensuring smooth, reliable operation even under heavy loads.

Strong Support Structure: The solid construction of the machine minimizes vibrations and ensures stability during operation, even when sanding large or heavy workpieces.

Long-Lasting Belts: The sanding belts are designed to withstand prolonged use, providing consistent results over time and reducing the frequency of belt changes.

This durability ensures that the machine can handle the rigorous demands of industrial environments, making it an excellent investment for businesses looking to increase productivity and performance.

7. Easy Operation and Maintenance

The 3-Belt Metal Wide Belt Sander is designed with ease of use and maintenance in mind. The machine features an intuitive interface and user-friendly controls, allowing operators to quickly adjust settings for optimal results. Key user-friendly features include:

Adjustable Speed Controls: The machine offers adjustable belt speeds for different materials and tasks, ensuring the operator has complete control over the sanding process.

Dust Extraction System: A robust dust extraction system is incorporated to capture debris and dust generated during the sanding process, improving air quality and extending the lifespan of the machine.

Simple Belt Replacement: The sanding belts are easy to replace, and the machine's design allows for quick and hassle-free maintenance.

Automatic Belt Tracking: The machine features an automatic belt tracking system to ensure that the sanding belts remain centered and function optimally throughout the sanding process.

These features make the 3-Belt Metal Wide Belt Sander easy to operate, reducing training time and increasing productivity in the workshop.

Wet Belt Sander:

| Specification | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm |

| Max Working Height | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| Min Working Length | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| First Abrasive Belt Power | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW | 7.5 kW |

| Second Abrasive Belt Power | - | 5.5 kW | - | 5.5 kW | 5.5 kW | 5.5 kW |

| Third Abrasive Belt Power | - | - | - | 5.5 kW | - | 5.5 kW |

| Polishing Wheel Power | - | - | - | - | 5.5 kW | 5.5 kW |

| Rotating Motor Power | - | - | - | - | - | - |

| Feed Motor Power | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Lift Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW |

| Swing Motor Power | - | - | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Vacuum Motor Power | - | - | - | - | - | - |

| Machine Dimensions (L×W×H) | 1.8×1.5×1.8 m | 2.1×1.5×1.8 m | 2.1×1.5×1.8 m | 2.4×1.5×1.8 m | 2.4×1.5×1.8 m | 2.7×1.5×1.8 m |

| Machine Weight | 1000 kg | 1200 kg | 1200 kg | 1500 kg | 1500 kg | 1800 kg |

| Abrasive Belt Size | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm | 1520×400 mm |

Applications

The 400mm Wet Type Wide Belt Sander is highly versatile and can be used in various industries for a broad range of applications:

Automotive Manufacturing: Surface finishing of automotive parts, including body panels, engine components, and other precision parts.

Metal Fabrication: Ideal for deburring, polishing, and grinding metal parts used in machinery and equipment.

Stainless Steel Processing: Used for polishing stainless steel surfaces, removing oxide layers, and creating consistent surface textures.

Industrial Metal Parts: Great for deburring, cleaning, and finishing industrial metal components used in construction, aerospace, and heavy machinery.