12-axis 4100mm High-Quality CNC Metal Stainless Steel Sheet Metal Bending Machine, specifically designed for bending and folding metal plates:

Key Features

Bending Capacity

Length: Up to 4100mm, suitable for large stainless steel sheets.

Thickness: Capable of handling various thicknesses, typically from 0.5mm to 10mm, depending on material type.

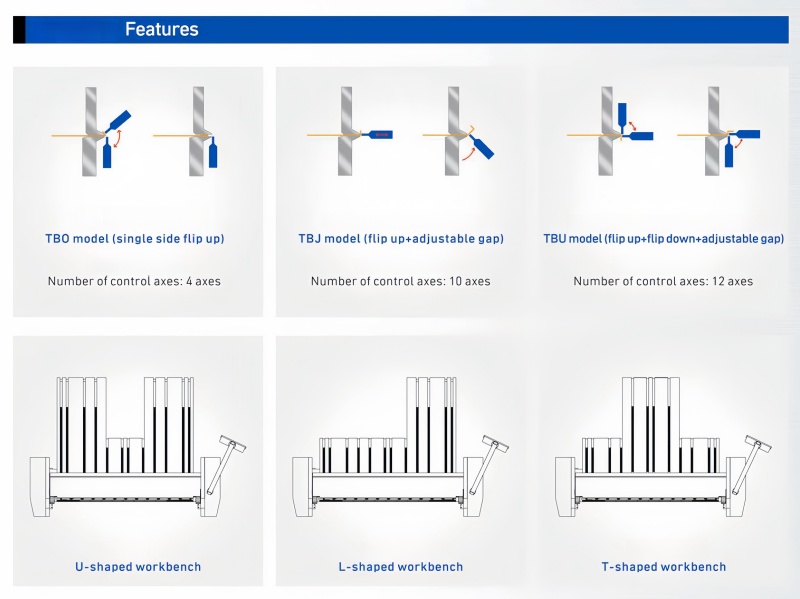

12-Axis Control

Multi-Axis Functionality: The machine features 12 axes for complex bending operations, allowing for intricate designs and shapes.

Precision Servo Drives: Each axis is controlled by servo motors, ensuring high accuracy and repeatability.

High-Quality Construction

Robust Design: Made with a strong and rigid frame to maintain stability during operation, resulting in high-quality bends.

Stainless Steel Compatibility: Specifically designed for bending stainless steel sheets, ensuring optimal performance and longevity.

Advanced Tooling

Customizable Tools: Equipped with various bending tools, including sharpnose and segmented tools, to accommodate different angles and widths.

Automatic Tool Change: Features may include an automatic tool-changing system for increased efficiency and reduced downtime.

Control System

CNC Control Panel: User-friendly interface, often with a touchscreen that allows for easy programming and operation.

Graphic Software: Advanced graphical representation for better visualization of the bending process, making programming intuitive.

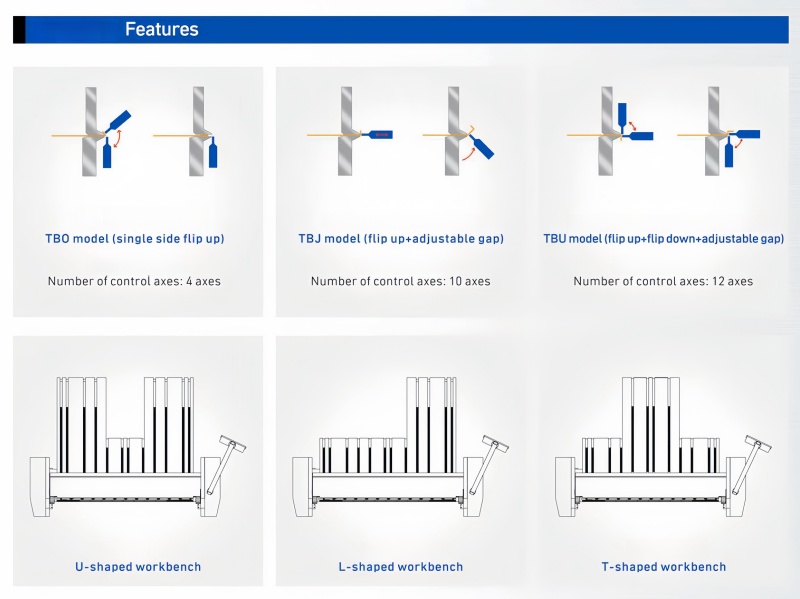

Backgauge System

Servo-Driven Backgauge: A precise backgauge system to ensure accurate positioning of sheets before bending.

Support Table: Includes a rectangular sheet support table to stabilize large workpieces during operation.

Safety Features

Applications

Manufacturing: Ideal for producing components in industries like automotive, aerospace, and HVAC.

Custom Fabrication: Perfect for shops needing to produce bespoke metal parts and prototypes.

High-Volume Production: Suitable for batch production due to its fast cycle times and high precision.

Benefits

Increased Efficiency: With multi-axis control and automatic features, the machine reduces setup times and increases throughput.

Enhanced Quality: Precision bending minimizes waste and improves the consistency of the finished product.

Versatile Applications: Able to handle various stainless steel grades and thicknesses, making it suitable for a wide range of projects.

Applications

This type of CNC folding machine is commonly used in industries such as:

Automotive: For producing parts like brackets, frames, and enclosures.

Aerospace: Manufacturing components that require high precision and quality.

HVAC: Creating ductwork and other components.

Metal Fabrication Shops: General-purpose bending and folding for custom projects.

Electronics: Producing enclosures and mounts for electronic devices.

Recommended Brands

When considering a 10-axis, 2500mm CNC sheet metal folding machine, look for reputable manufacturers such as:

Amada

Trumpf

Bystronic

EHT

LVD

Technical Parameter

| Item | Unit | TB025 | TB032 | TB041 | TBJ25 | TBJ32 | TBJ41 | TBU25 | TBU32 | TBU41 |

| Bending thickness (carbon steel) | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Bending thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending angle range | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | -45...+45 | -45...+45 | -45...+45 |

| Max. bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Rear positioning length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Open height | mm | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Bending tool height | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| Control axis number |

| 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Pressing speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Bending speed | m/s | 5.0 | 5.0 | 5.0 | 6.5 | 6.5 | 6.5 | 7.0 | 7.0 | 7.0 |

| Motor energy consumption | kW | 3.5 | 4.5 | 6.1 | 3.5 | 4.5 | 6.1 | 5.5 | 7.0 | 10.0 |

| External dimensions (L × W × H) | mm | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5300×2150 | 3100×1650 | 3800×1950 | 5700×2150 |

| Weight | kg | 4500 | 5300 | 7500 | 4500 | 5300 | 7500 | 4900 | 7000 | 11000 |

This table provides information on various models of CNC sheet metal folding machines, highlighting their specifications such as bending thickness, bending angle range, maximum bending length, open height, speed, motor energy consumption, dimensions, and weight.

Recommended Models:

Some well-regarded brands that manufacture high-quality CNC sheet metal folding machines include:

Amada: Known for advanced technology and high-quality machines suitable for various bending applications.

Trumpf: Offers innovative solutions and robust machines for efficient sheet metal processing.

Bystronic: Features user-friendly interfaces and reliable performance for bending and folding tasks.

EHT: Provides a range of CNC folding machines with customizable features to meet specific production needs.

Applications:

CNC folding machines are widely used in industries such as:

Automotive manufacturing

Aerospace components

HVAC systems

Electrical enclosures

Furniture manufacturing